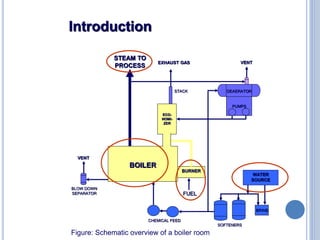

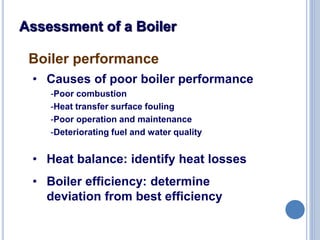

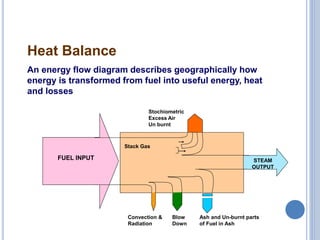

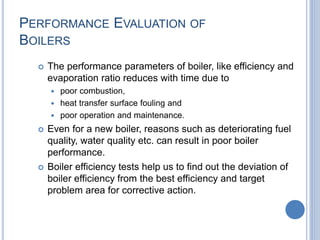

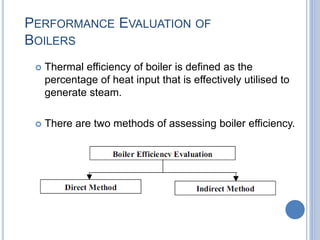

A boiler provides a means for combustion heat to be transferred to water and turned into steam or hot water. It has three main systems - the feed water system, steam system, and fuel system. Heat is transferred from the burning fuel via radiation, convection and conduction to heat the water inside the boiler. Boilers can be evaluated to determine their efficiency and identify areas for improvement, such as reducing stack gas temperature, preheating feed water, improving combustion, and reducing heat losses.

![ENERGY CONSERVATION

Topic “Boiler”[ 1 ]](https://image.slidesharecdn.com/energyconservationboiler-190301092256/75/Energy-conservation-boiler-1-2048.jpg)

![[ 20 ]

PERFORMANCE EVALUATION OF

BOILERS](https://image.slidesharecdn.com/energyconservationboiler-190301092256/85/Energy-conservation-boiler-20-320.jpg)

![[ 37 ]

ENERGY CONSERVATION

OPPORTUNITIES](https://image.slidesharecdn.com/energyconservationboiler-190301092256/85/Energy-conservation-boiler-37-320.jpg)

![[ 52 ]

Engr. Ahsanullah Soomro](https://image.slidesharecdn.com/energyconservationboiler-190301092256/85/Energy-conservation-boiler-52-320.jpg)