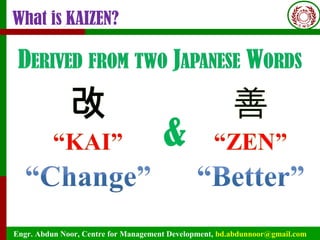

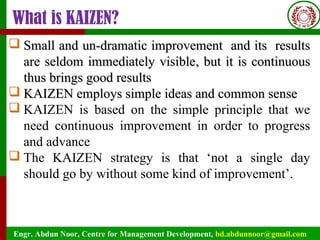

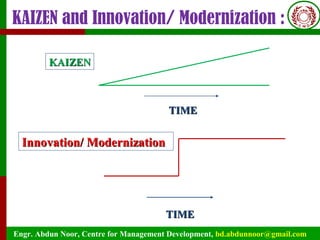

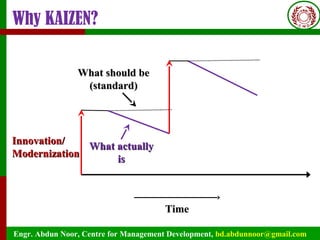

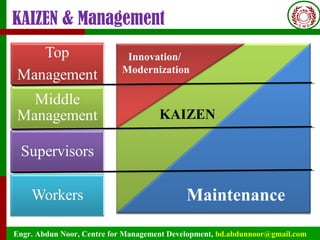

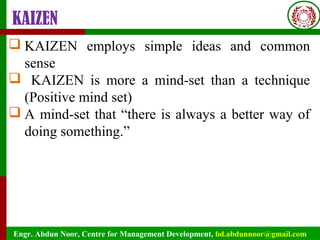

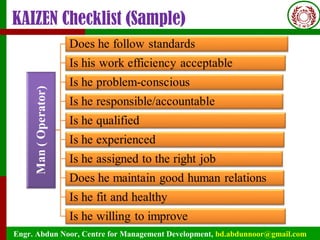

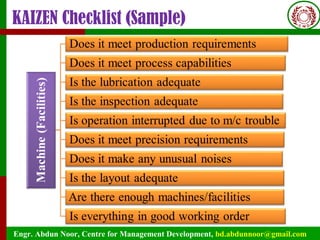

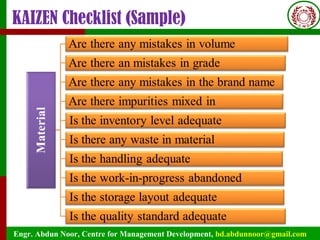

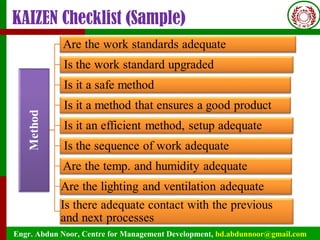

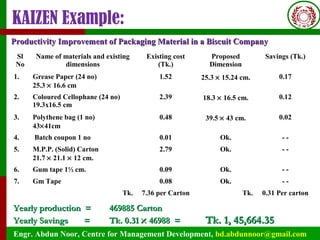

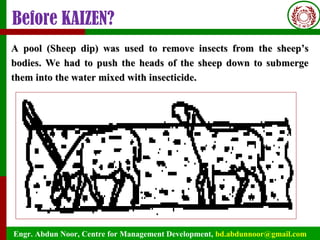

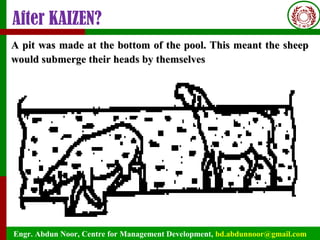

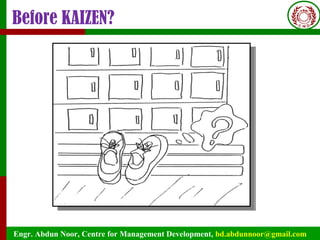

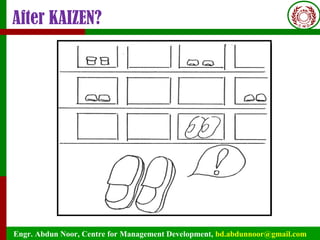

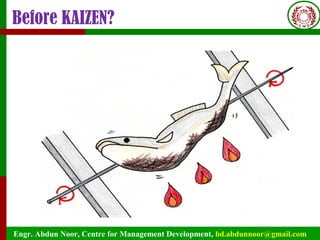

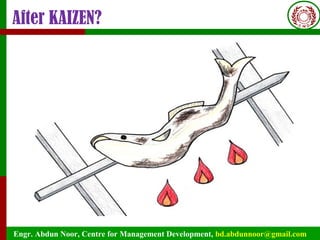

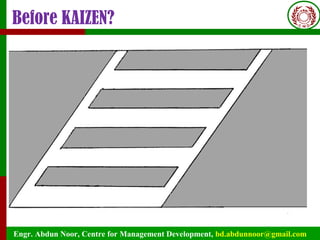

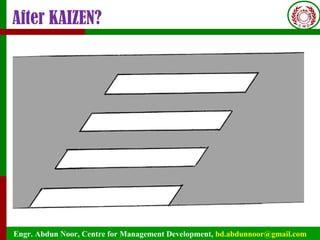

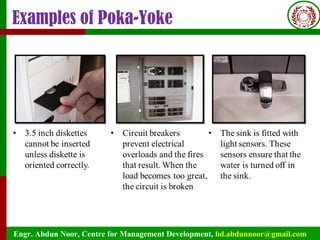

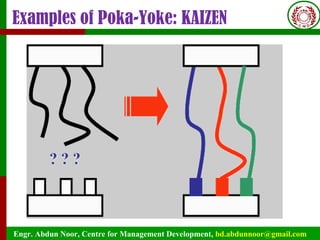

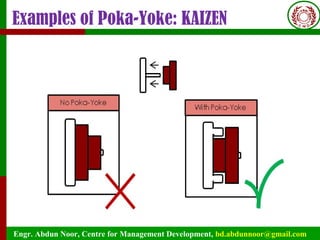

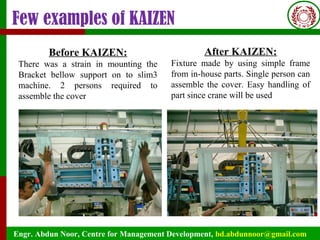

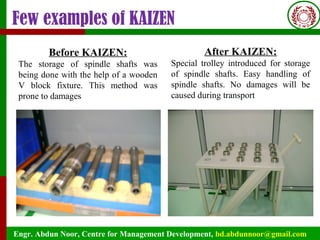

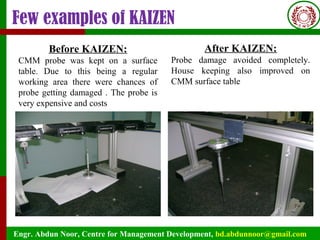

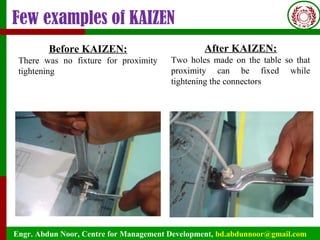

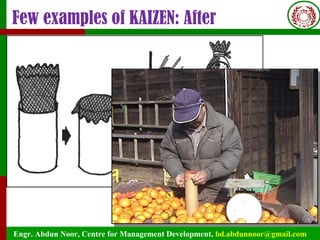

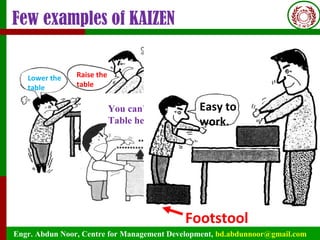

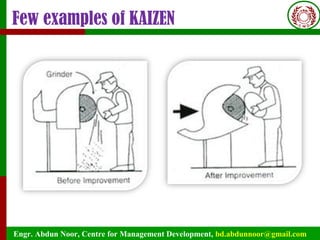

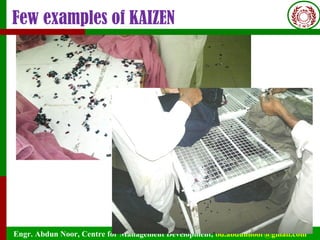

The document discusses the concept of 'Kaizen,' emphasizing continuous, small improvements in processes and practices for better efficiency and productivity. It outlines critical principles of Kaizen, such as the avoidance of waste, strain, and errors, while differentiating it from innovation, which requires significant investment. Examples illustrate how Kaizen can lead to tangible improvements in various contexts, from packaging materials to operational efficiency.