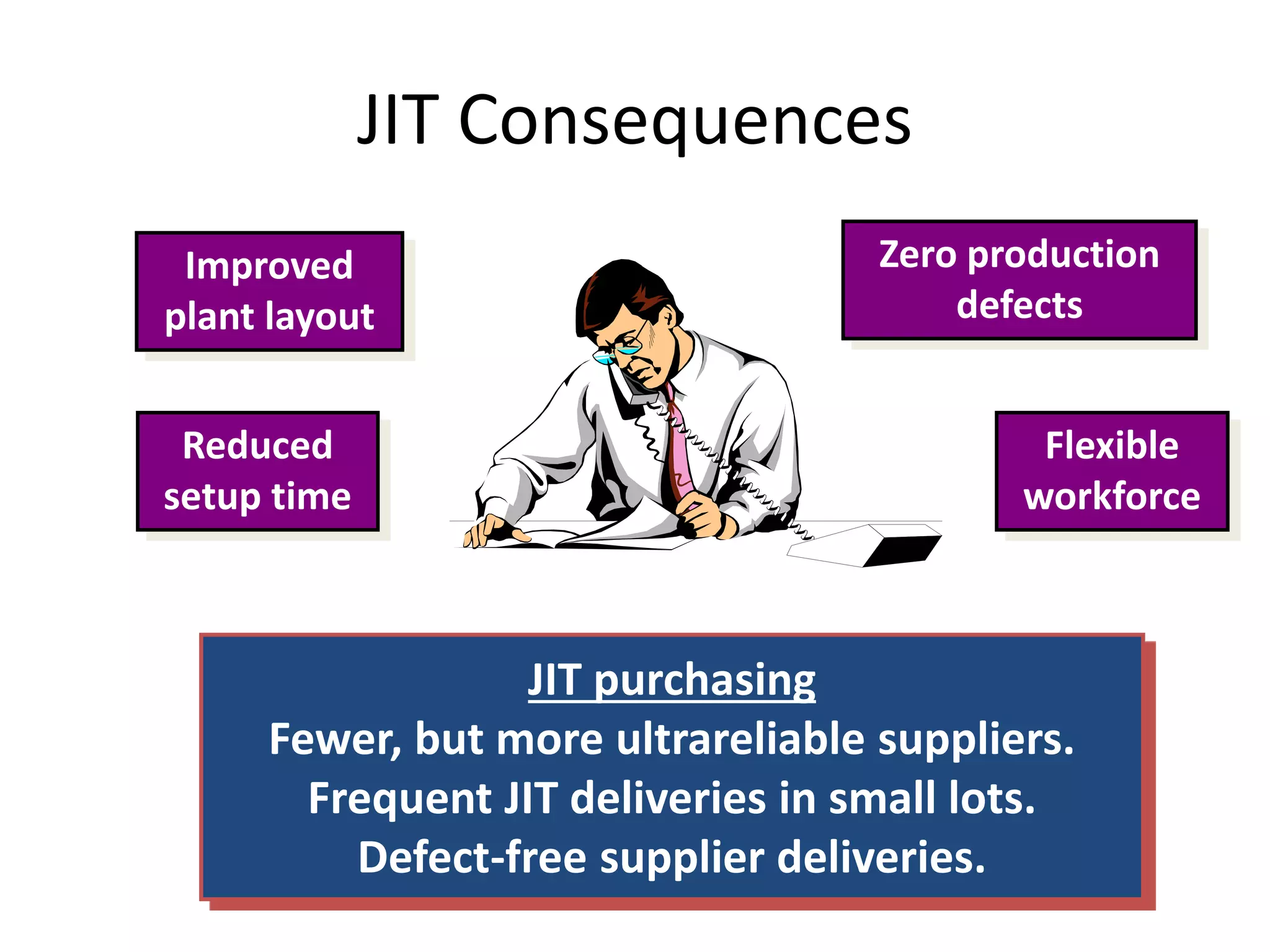

Just-in-Time (JIT) is a set of techniques to increase productivity, improve quality, and reduce costs through eliminating waste and continuous improvement. Key characteristics of JIT include a pull method of production, small lot sizes, close supplier ties, and flexible workforces. The goals of JIT are to have complete products and parts arrive just in time for assembly or production by receiving customer orders, materials, and production schedules. Benefits of JIT include reduced inventory costs, higher quality products, and more rapid responses to customer orders.