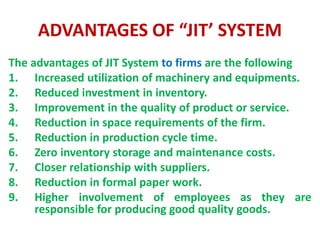

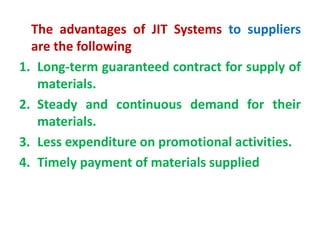

The Just-In-Time (JIT) manufacturing system aims to achieve high production volumes with minimal inventories. It eliminates raw material, work in progress, and finished goods inventories by producing goods only as needed. Successful implementation requires transforming work methods, responsibilities, and organization, and is based on continuous improvement through employee involvement and total quality control.