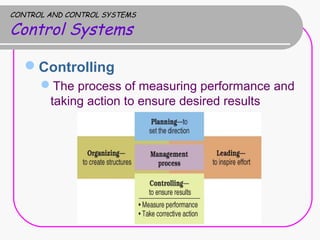

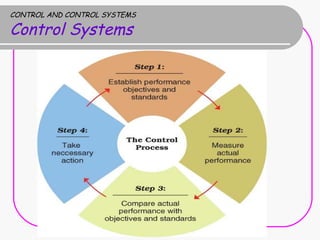

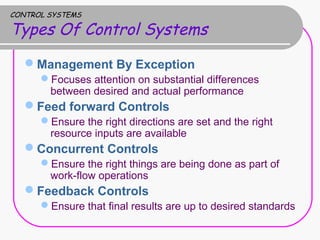

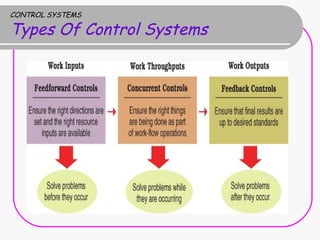

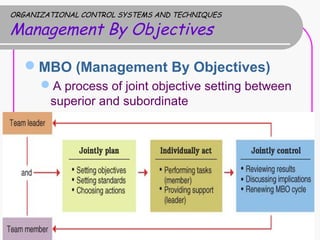

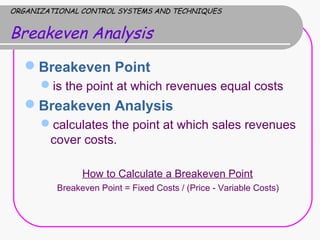

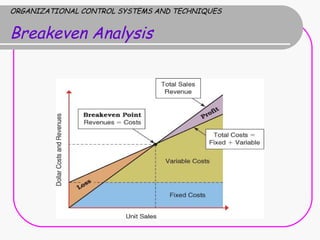

The document discusses control systems and techniques used in organizations. It defines controlling as measuring performance and taking action to ensure desired results. There are four main types of control systems: management by exception which focuses on substantial differences between goals and results; feed forward which ensures the right directions and resources; concurrent which ensures the right processes; and feedback which ensures final results meet standards. Some organizational control techniques discussed include management by objectives, employee discipline, quality control, purchasing/inventory controls, and breakeven analysis.