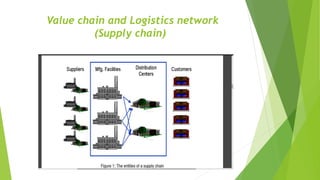

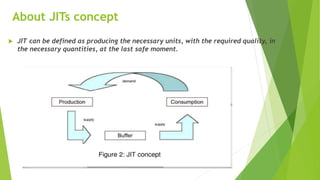

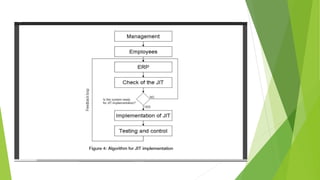

This document discusses just-in-time (JIT) manufacturing. It defines JIT as producing the necessary units with the required quality and quantities at the last safe moment. The technique was first used by Ford in the 1920s and adopted by Toyota in 1954. JIT requires accepting a philosophy of maintaining the right materials, at the right time, at the right place, and in the exact amount. Benefits include reduced waste and improved efficiency, while problems include susceptibility to interruptions. Successful implementation requires employee acceptance, an ERP system, and dependable suppliers. Real-life examples that achieved success with JIT principles are Toyota, Dell, and Harley Davidson.