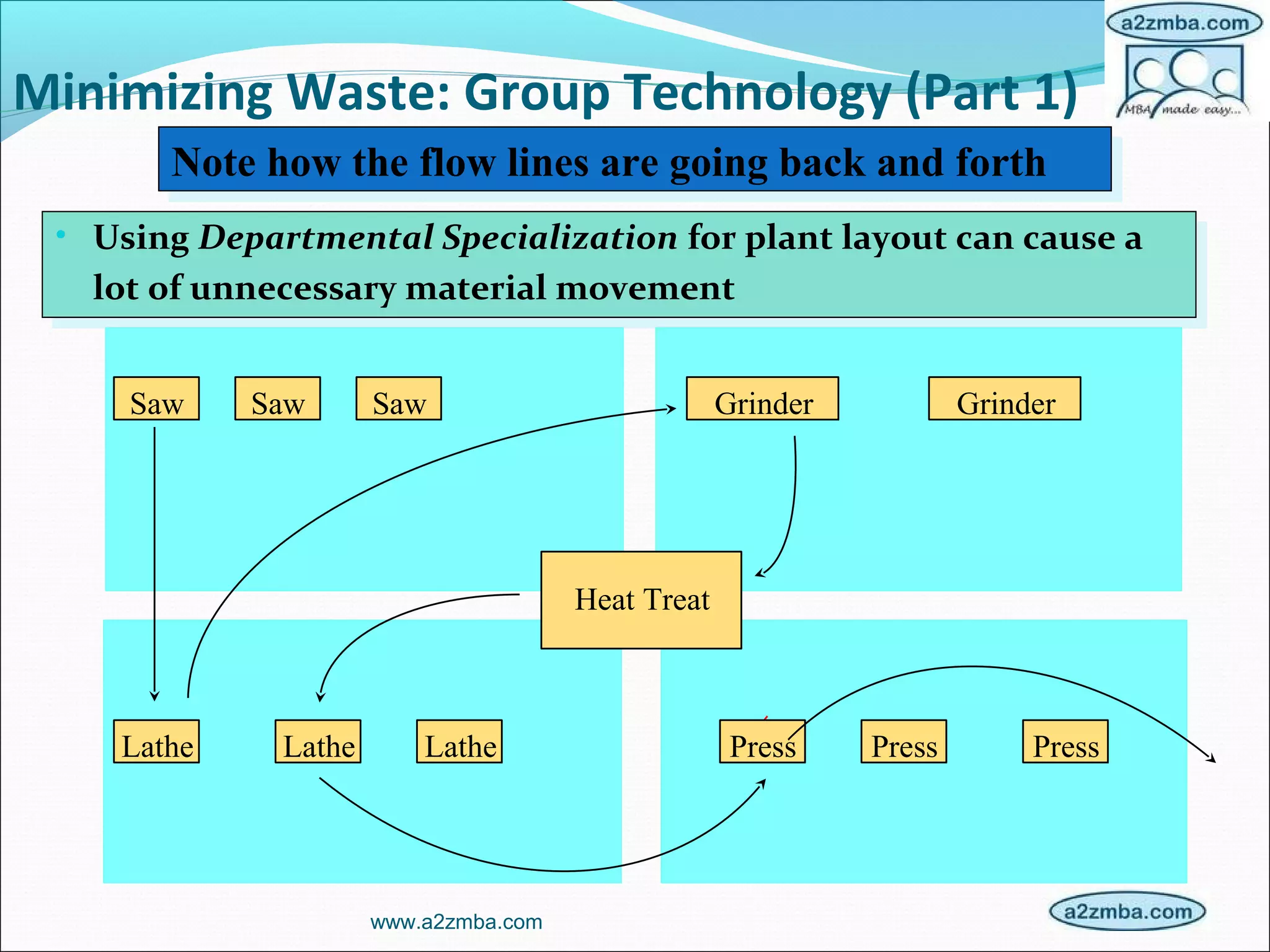

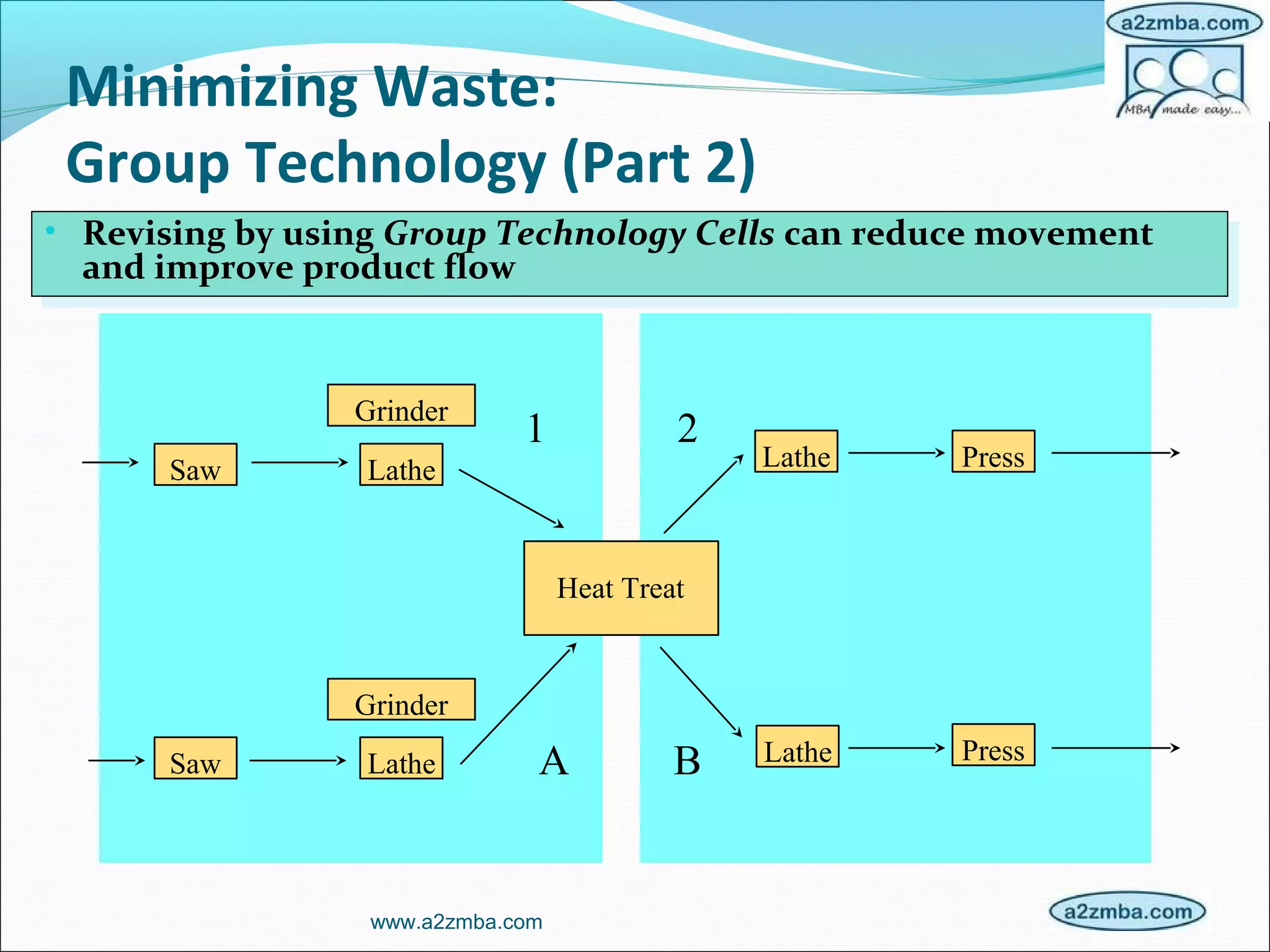

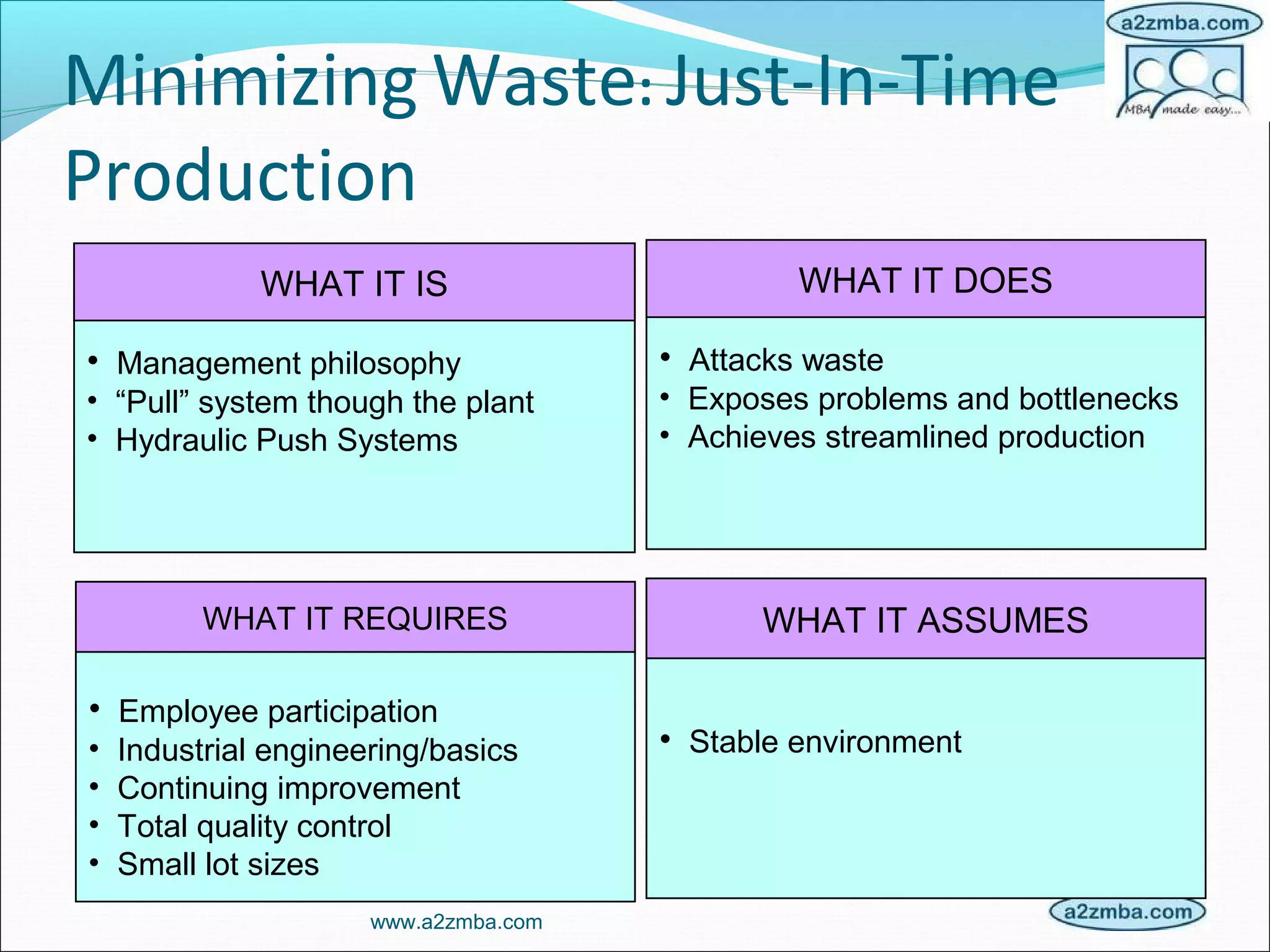

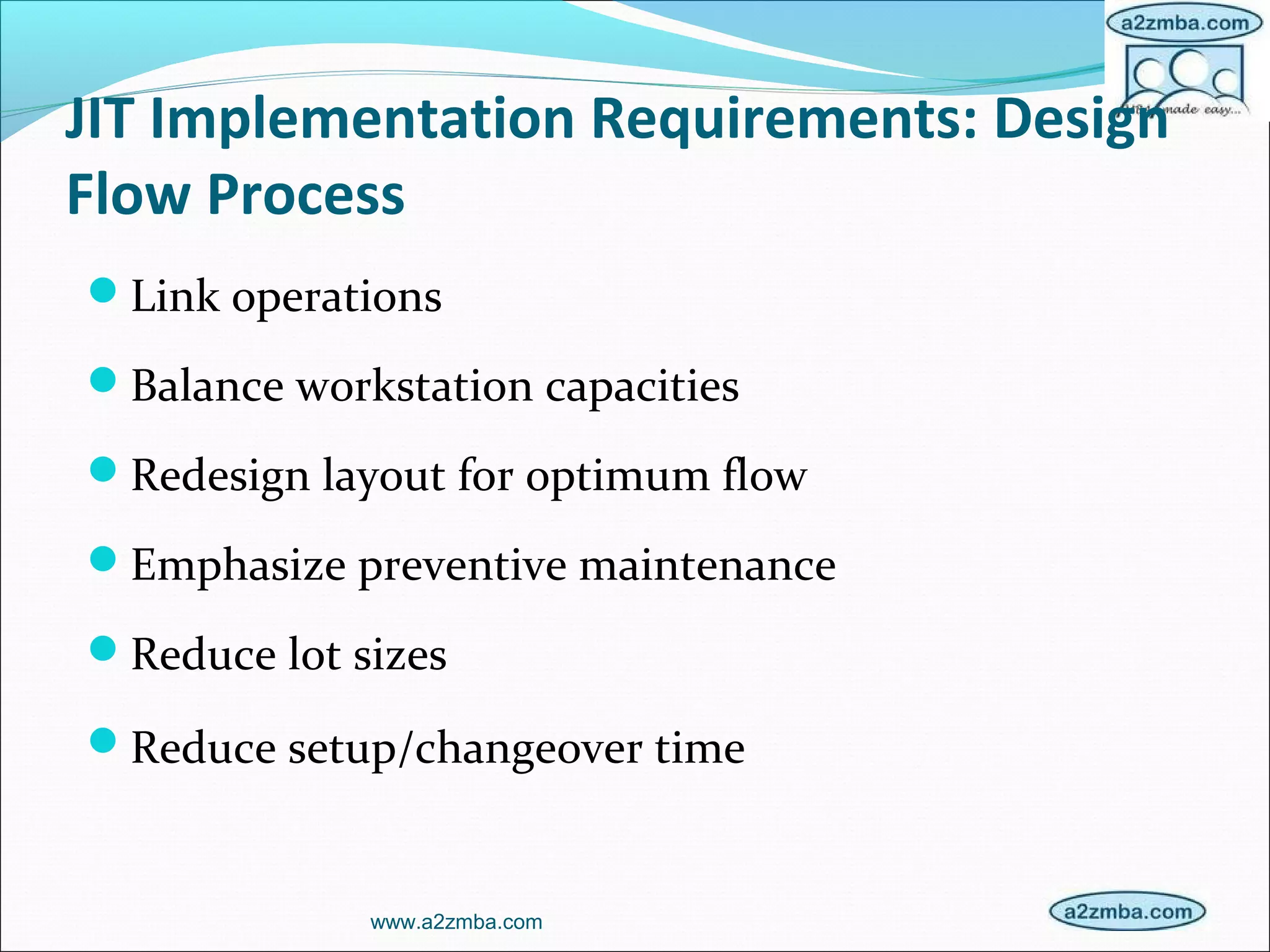

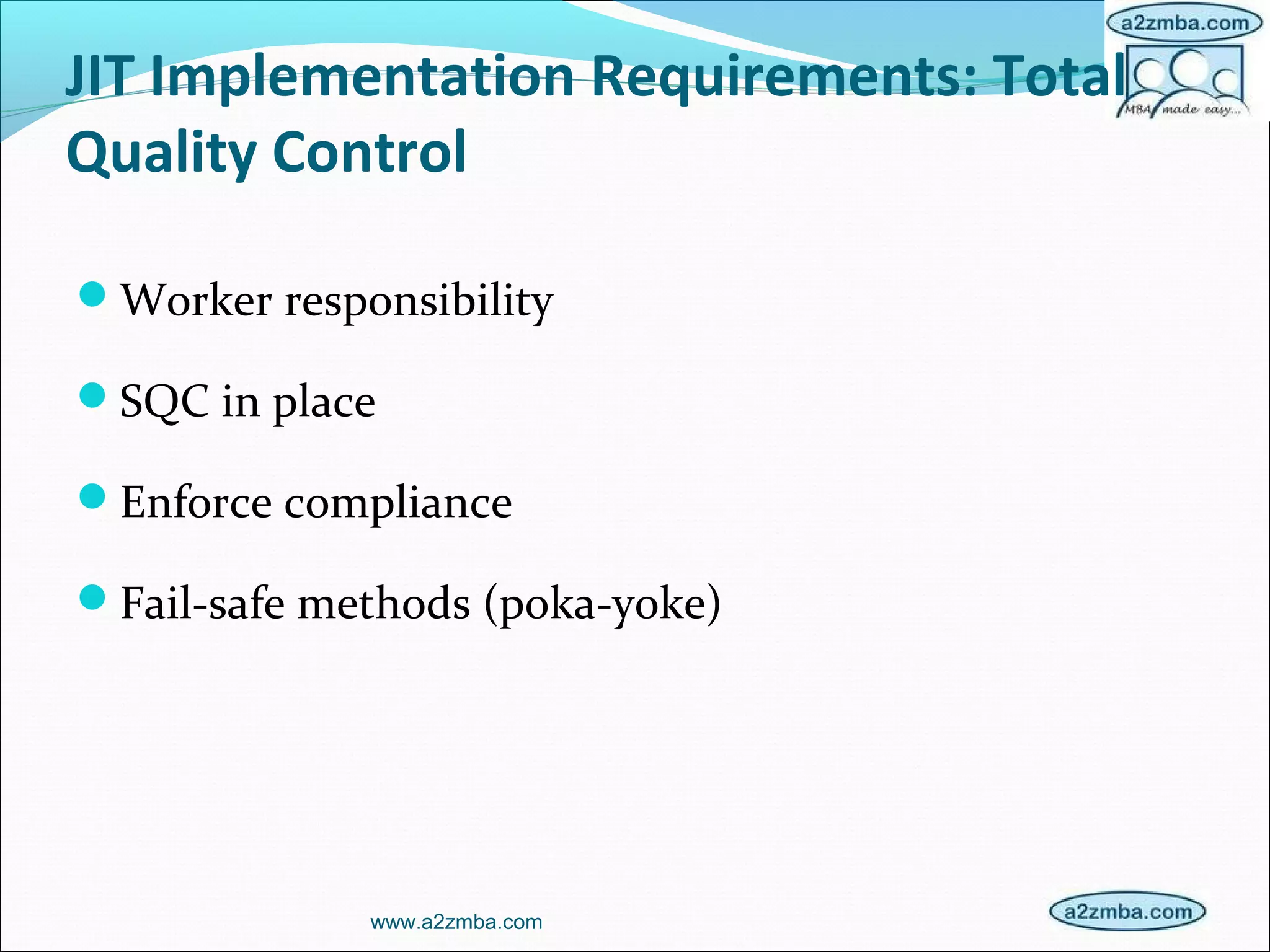

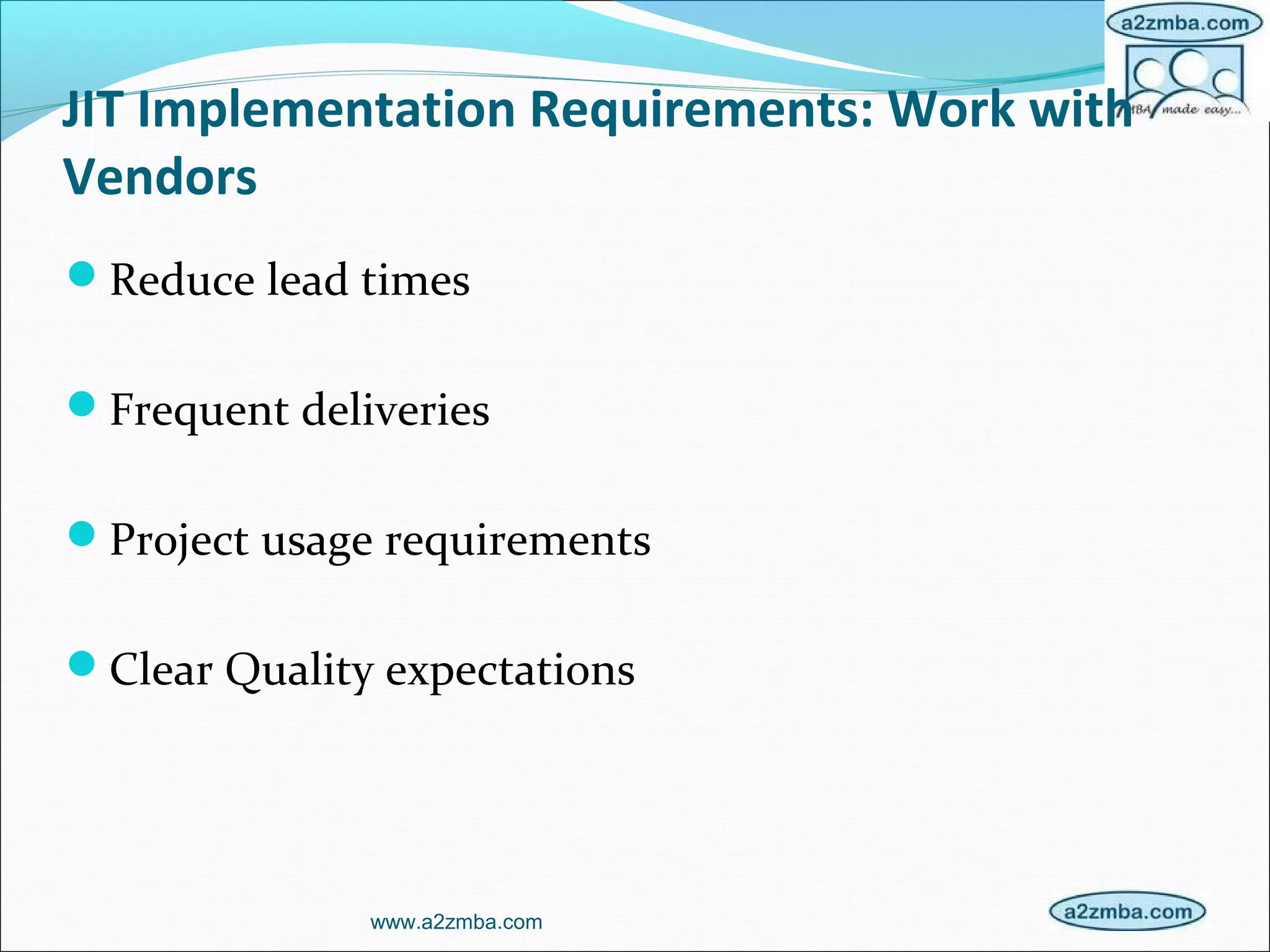

Just-in-Time (JIT) manufacturing is a philosophy aimed at eliminating waste by producing only what is needed when it is needed. It emphasizes reducing inventory, defects, transportation, and other non-value added activities. The evolution of JIT in Japan was driven by resource scarcity following World War 2. JIT identifies seven types of waste and techniques like group technology, small lot sizes, continuous improvement, and quality control to minimize waste in production processes and the flow of materials. Proper implementation of JIT requires redesigning operations for optimal flow, reducing setup times, developing supplier partnerships, and ongoing performance measurement.