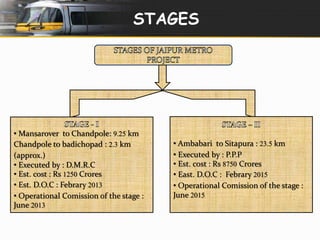

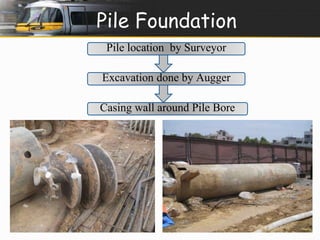

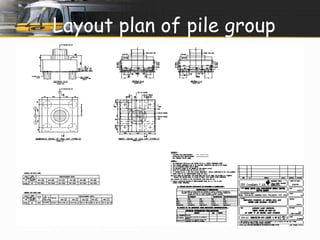

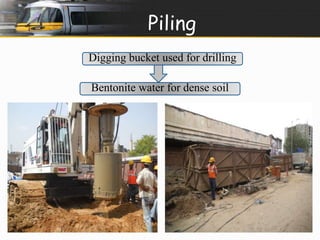

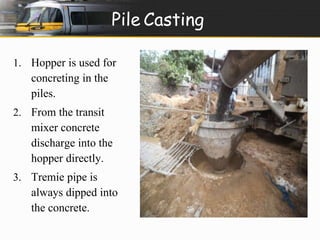

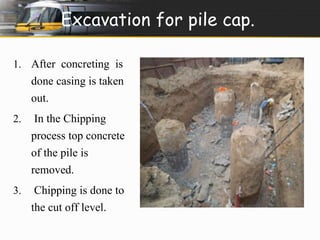

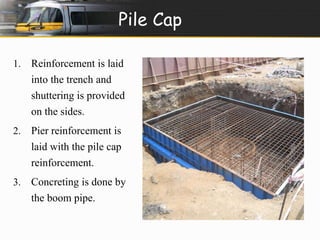

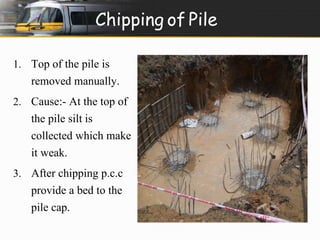

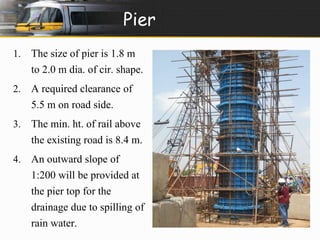

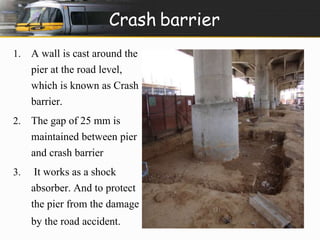

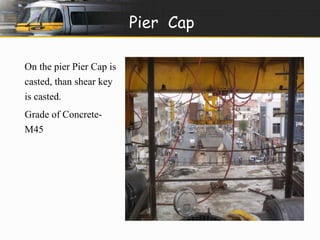

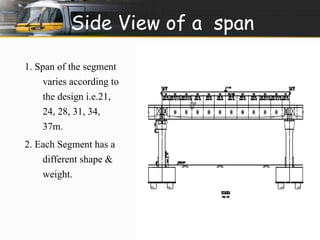

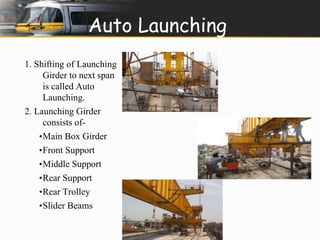

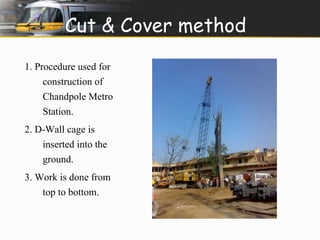

The document summarizes the Jaipur Metro Rail project. It discusses that the project was incorporated in 2010 as Jaipur Metro Rail Corporation Limited. The project has two stages - the first stage from Mansarover to Badichopad will be 11.55 km and operational by June 2013, and the second stage from Ambabari to Sitapura will be 23.5 km and operational by June 2015. It then provides details about the various construction methods used for the project, including piling, pile caps, piers, precast segmental construction, cut-and-cover construction, and ramp construction.