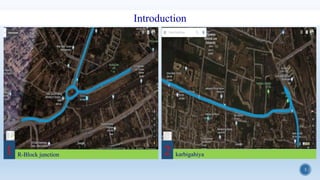

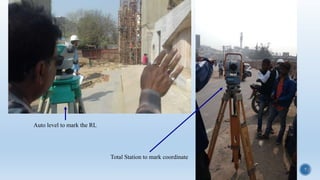

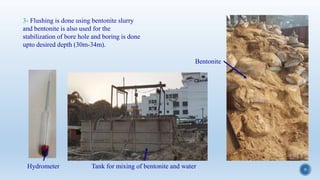

This document presents information on the construction of a flyover in Patna, Bihar, India. It discusses two proposed flyover projects connecting Mithapur flyover to Bhikhari Thakur flyover and Mithapur flyover to Chiraiyatand flyover. The contractor for the project is Rachna Construction Co. from Bharuch, Gujarat. The document then provides details on the execution of the project, including surveying, piling, pile cap construction, pier shaft construction, and testing procedures to ensure quality. It concludes by noting that flyovers make transportation easier but constructing them inside cities is difficult due to traffic interruptions during foundation work.