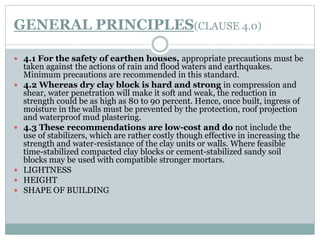

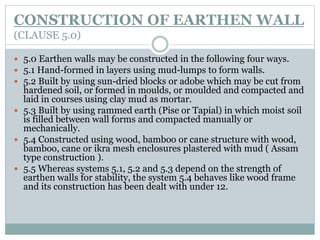

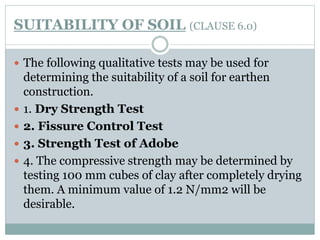

This document provides guidelines for improving the earthquake resistance of earthen buildings according to Indian Standard IS 13827:1993. It covers terminology, general principles, and recommendations for construction features, wall types, and seismic areas. Key recommendations for seismic areas include limiting building height, restricting wall length and openings, adding buttresses and bands, and using reinforced wood or cane structures.