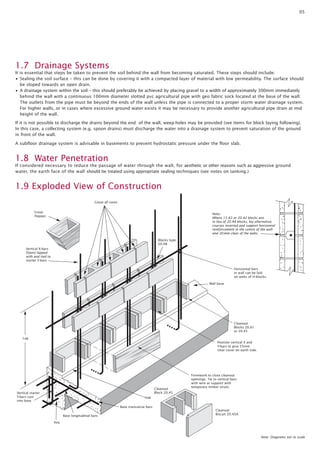

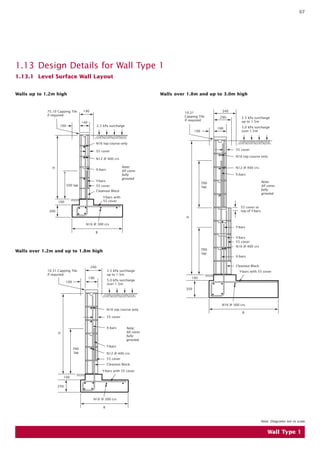

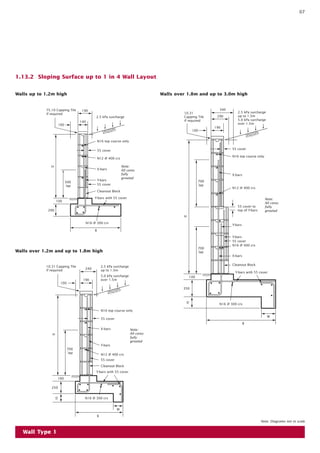

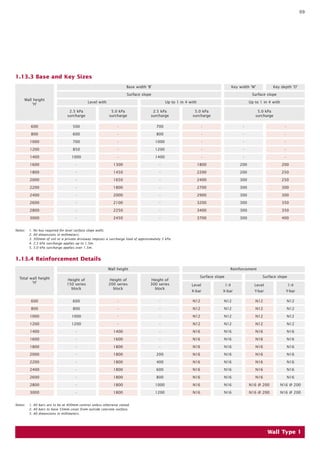

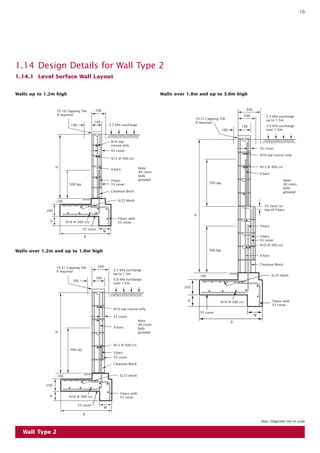

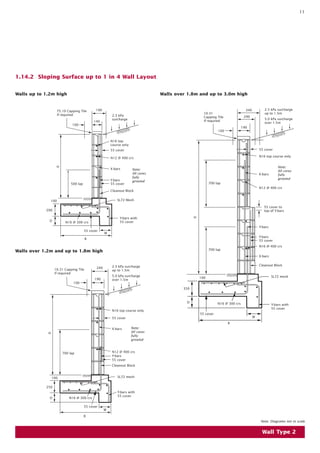

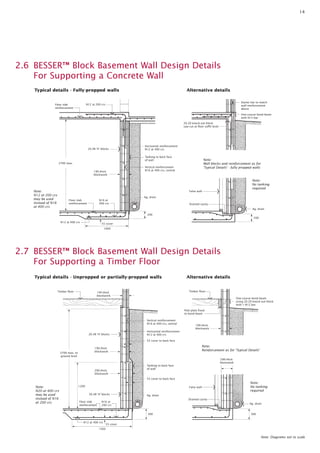

This document provides comprehensive guidance on building besser block walls, including reinforced retaining walls and basement walls, detailing design specifications, materials, and construction steps. It emphasizes the importance of proper drainage systems, soil classification, and foundational considerations while adhering to Australian standards. Additionally, it contains design details for various wall types and construction techniques to ensure structural integrity and performance.