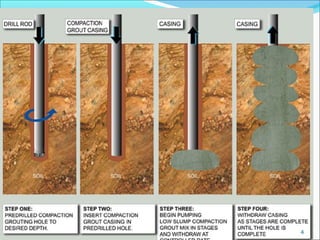

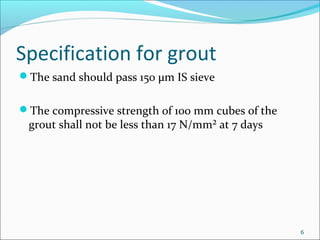

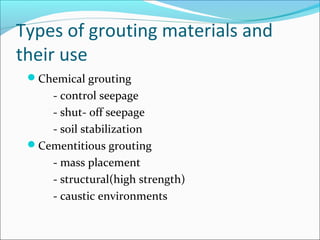

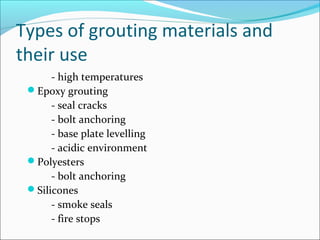

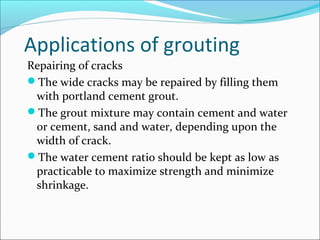

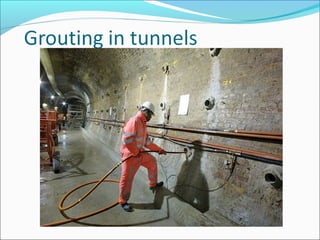

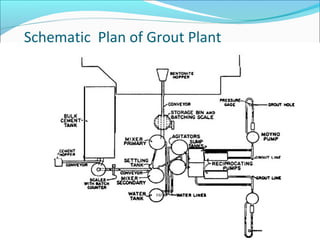

This document provides information on grouting and guniting processes. It defines grouting as placing a cementitious material into cavities to improve load capacity or repair structures. Grouting mixtures are described along with categories, properties, specifications and applications. Guniting is introduced as a technique using pneumatic application of cementitious mortar to rehabilitate structures like bridges and buildings. The document outlines equipment, procedures and processes for mixing, pumping and applying grouts and shotcrete.