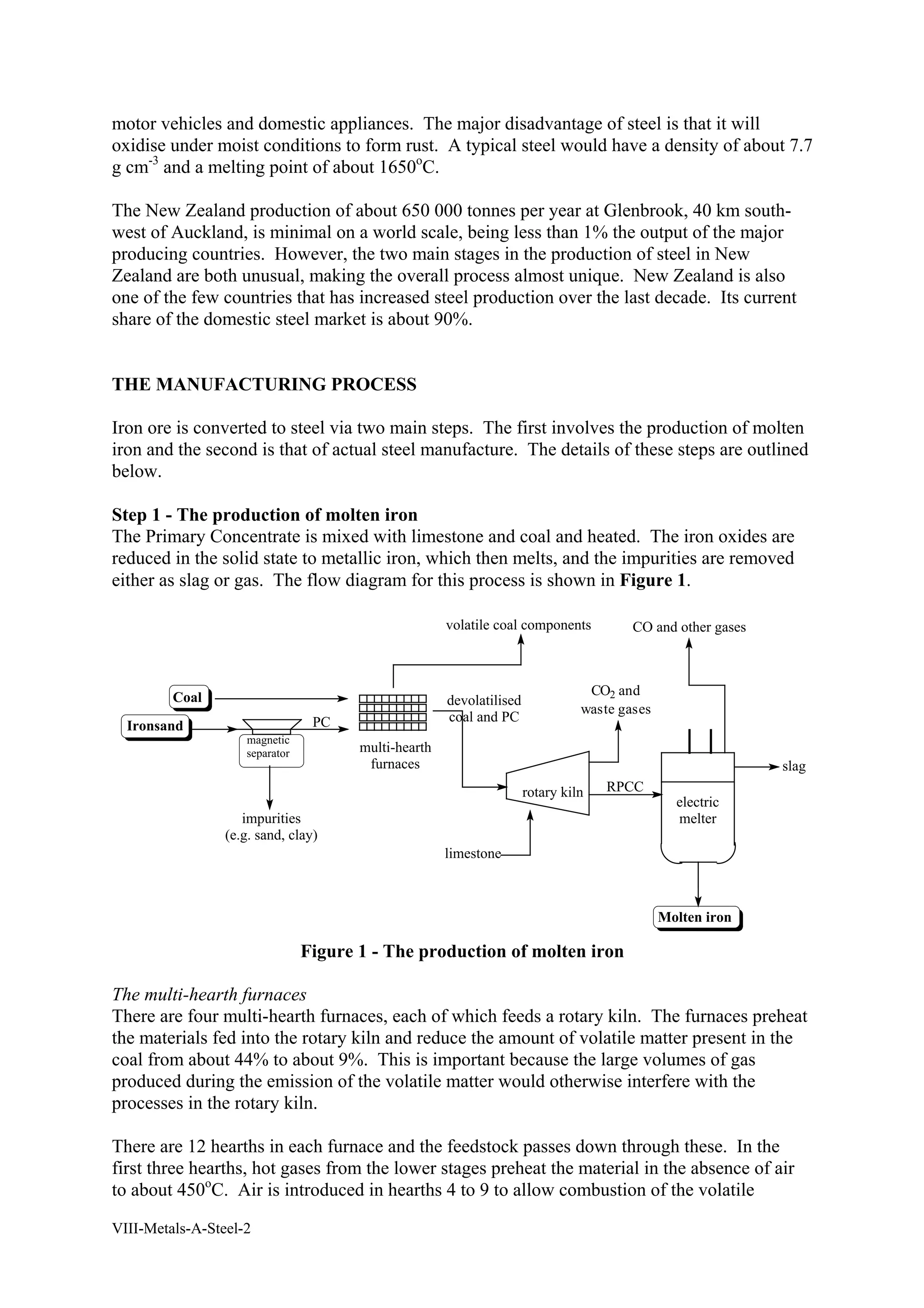

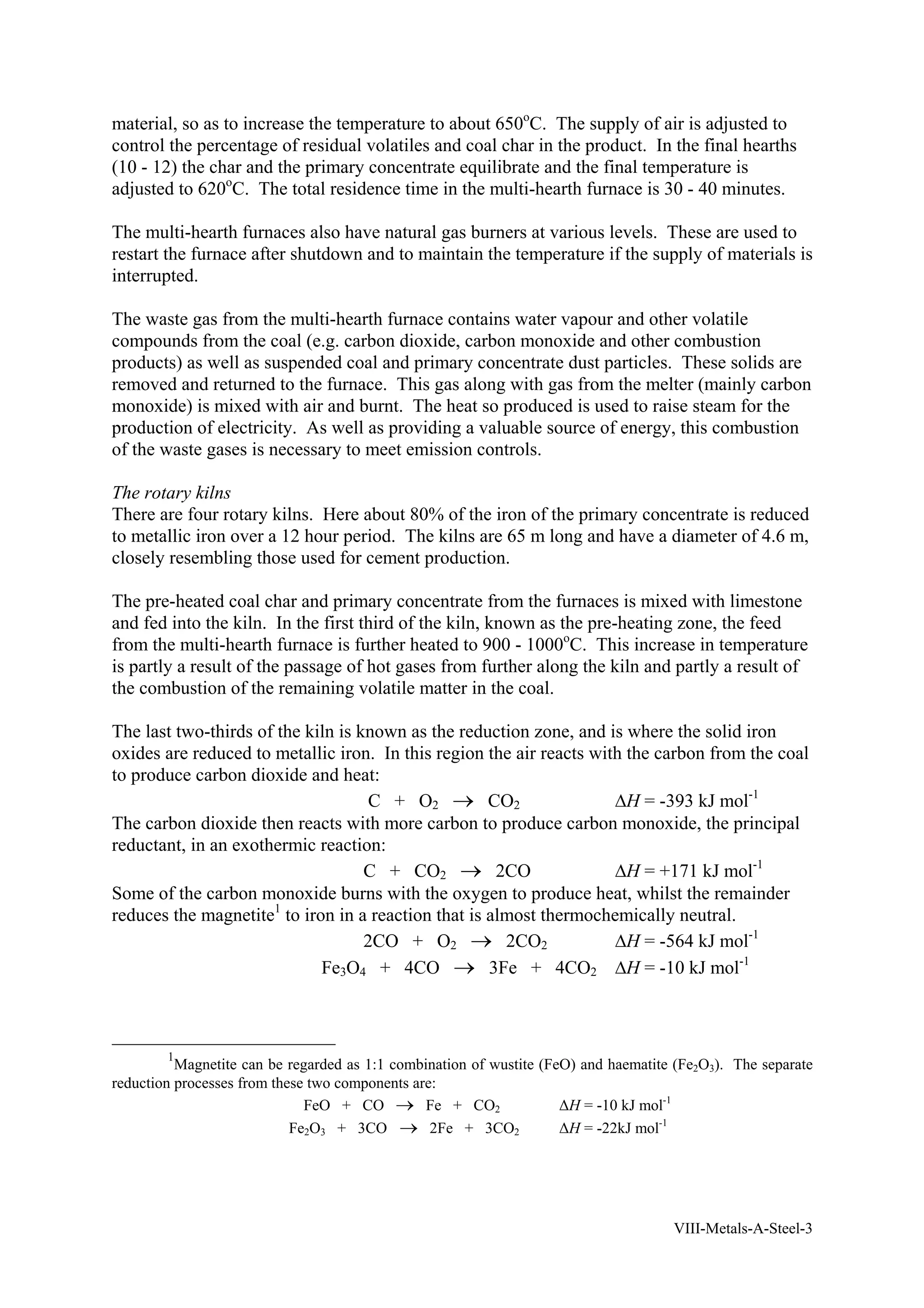

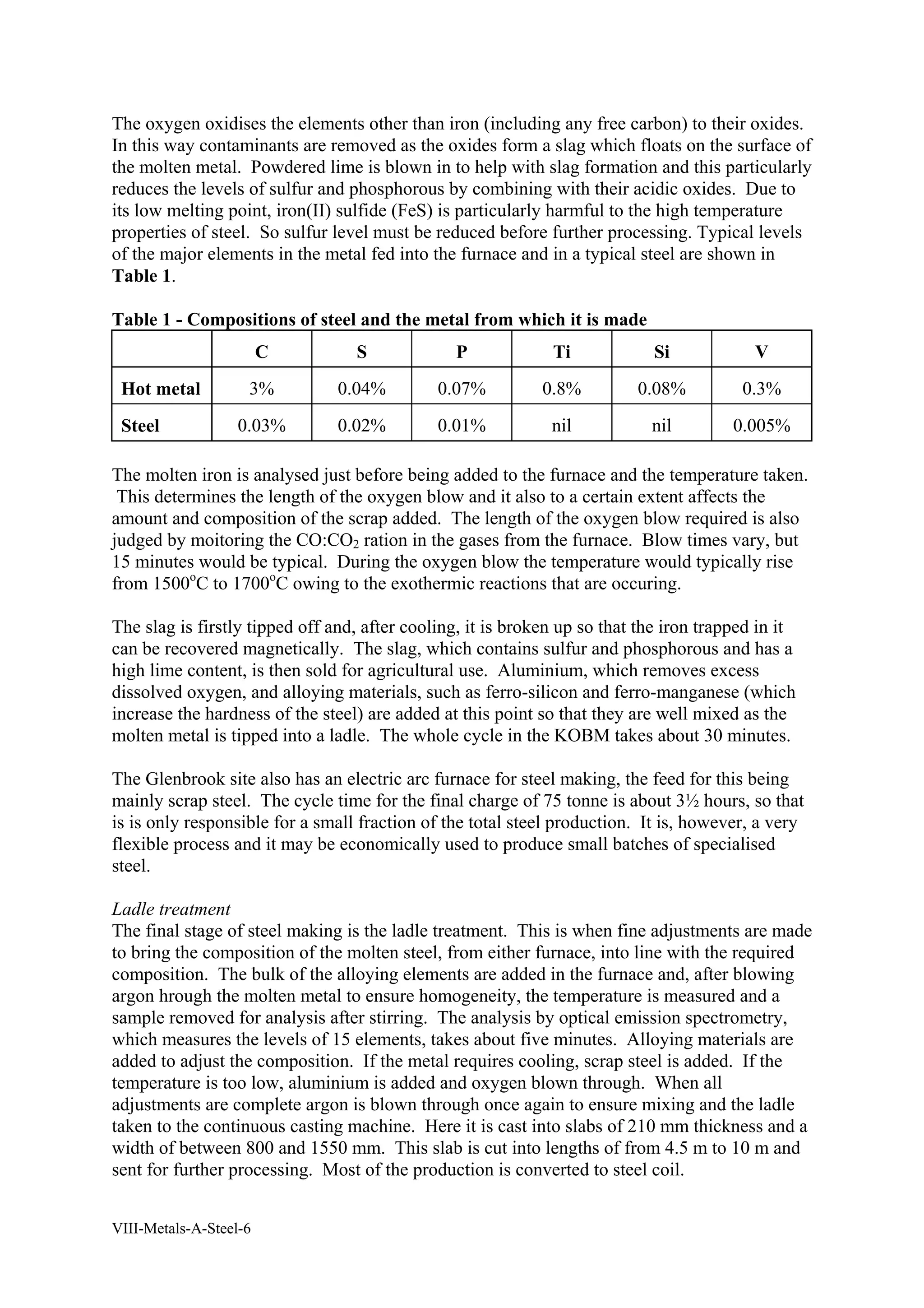

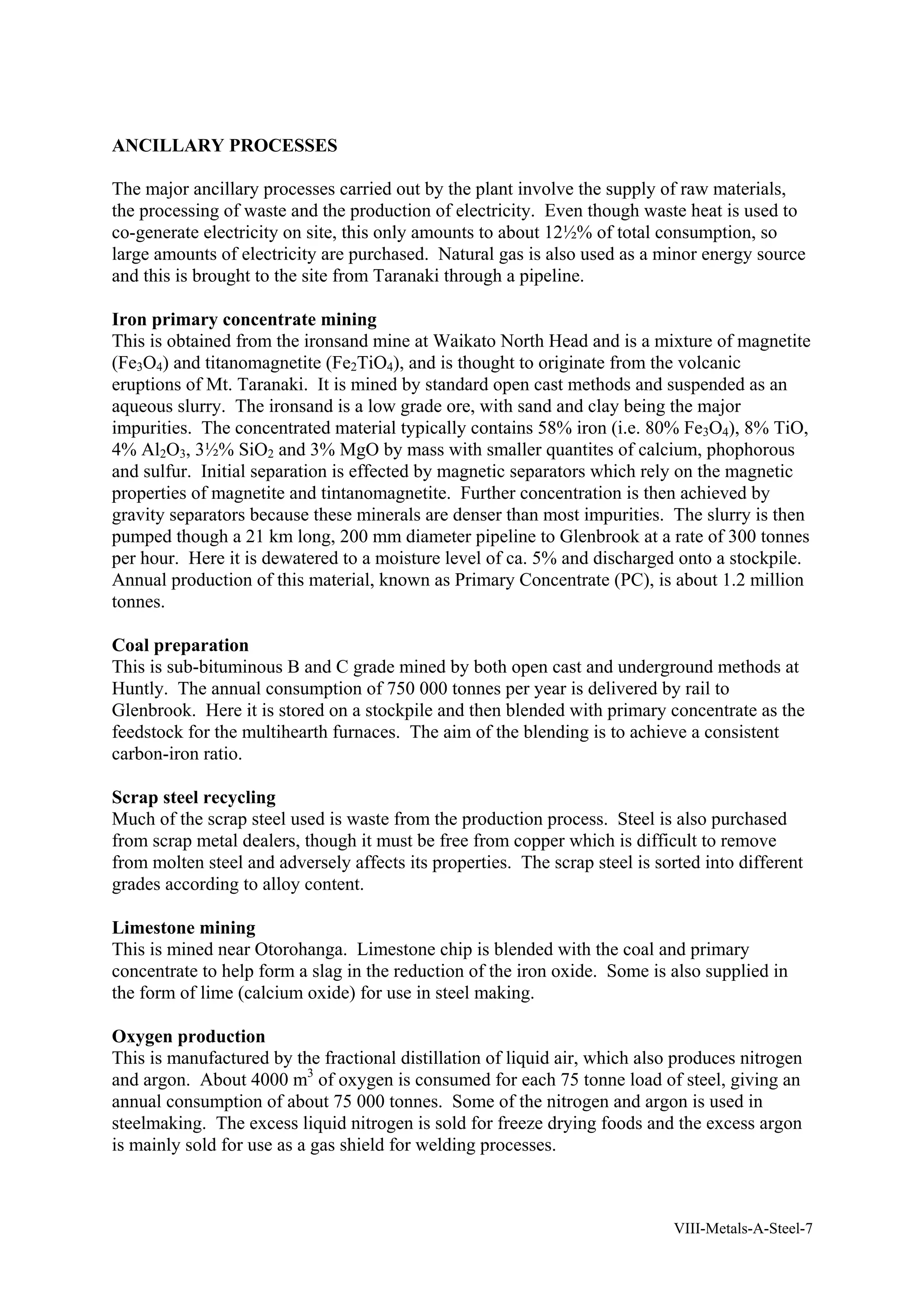

This document summarizes the process of steel manufacturing in New Zealand. Iron ore is first reduced to iron in rotary kilns, producing a substance called reduced primary concentrate and char. This is then melted into molten iron in electric melters. The molten iron undergoes vanadium recovery and is then converted to steel in a Klockner Oxygen Blown Maxhutte furnace. Oxygen is blown through the furnace to oxidize impurities, which are separated as slag. Alloying elements are then added to produce the final steel product.