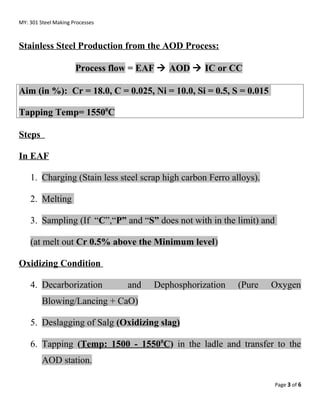

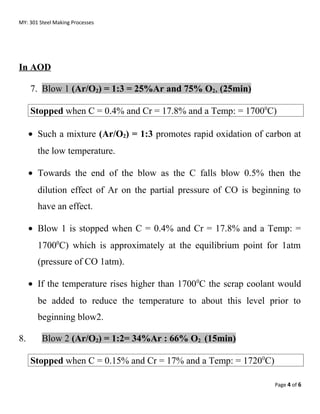

The document describes the argon-oxygen decarburization (AOD) process used in stainless steel production. The AOD process allows for precise control of carbon and alloy element levels by diluting oxygen with argon, enabling carbon to be removed while minimizing oxidation of chromium. The process involves melting scrap in an electric arc furnace, then transferring to an AOD vessel for multiple blows using varying ratios of argon and oxygen to sequentially lower carbon levels from 0.4% to 0.018%, while maintaining the target chromium level of 16.5%, before final adjustments and tapping.