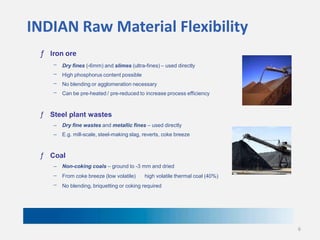

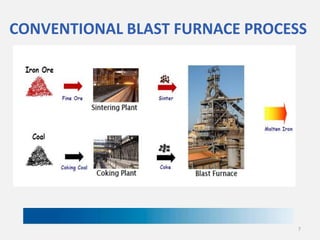

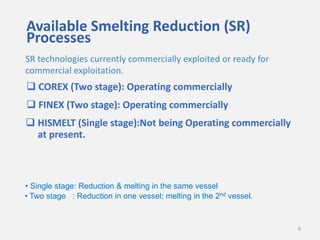

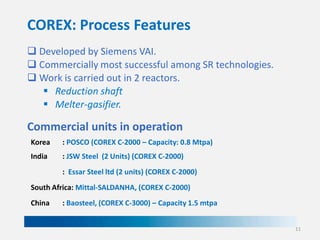

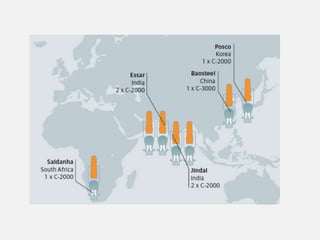

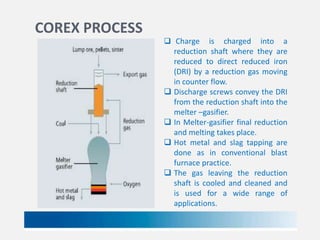

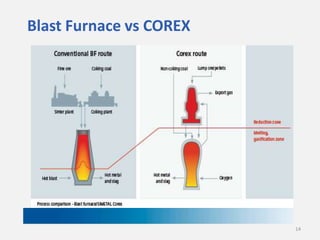

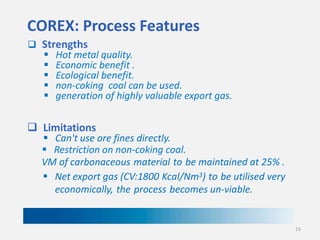

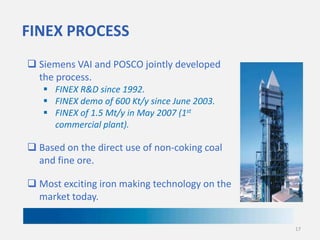

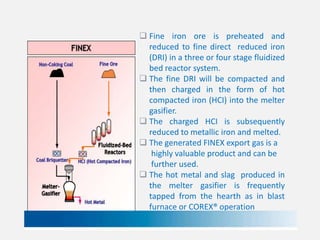

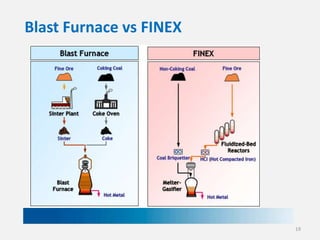

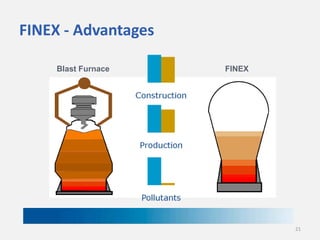

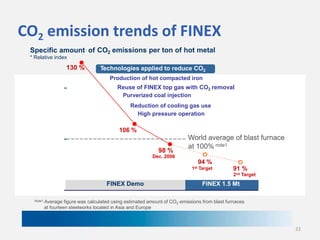

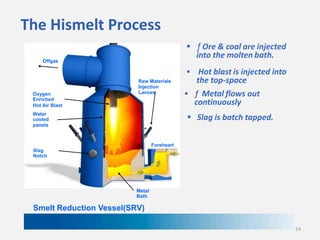

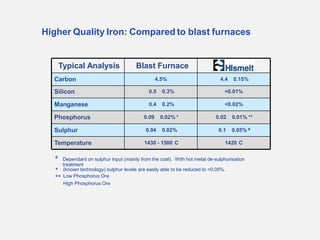

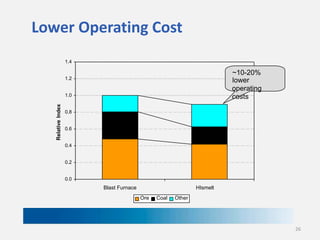

This document discusses alternative iron making processes that are more relevant for India given concerns over resource depletion, rising energy demands, and environmental regulations. It describes several emerging smelting reduction technologies including COREX, FINEX, and Hismelt that allow for more flexible use of raw materials like iron ore fines and non-coking coal. These processes aim to eliminate sintering and coke-making while producing high quality iron. COREX and FINEX have been implemented commercially while Hismelt offers potential cost savings over blast furnaces and lower environmental impact. Overall, alternative technologies are needed to sustainably meet India's growing steel demand given restrictions on raw material quality and availability.