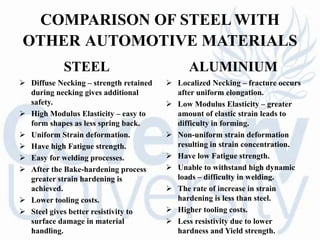

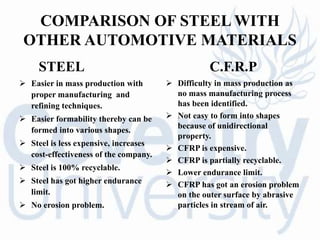

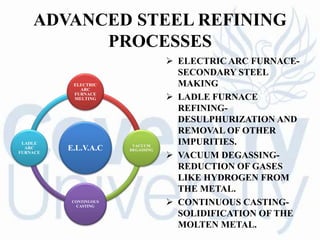

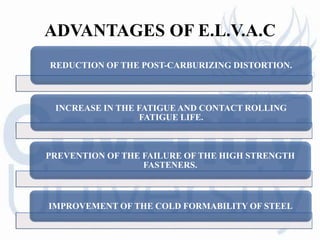

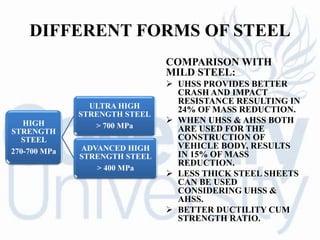

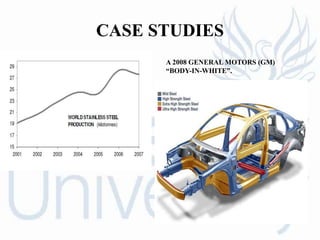

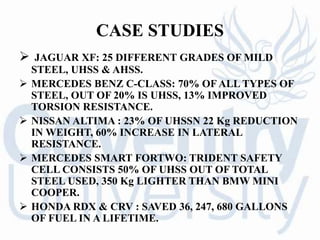

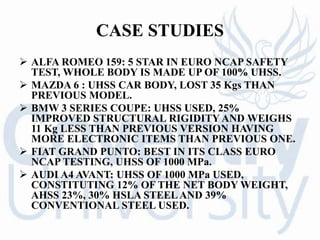

The document discusses steel used in manufacturing lightweight automobiles. It provides an overview of modern steelmaking processes and compares steel to other materials like aluminum and carbon fiber. Key points include that steel is the most cost-effective material, it is fully recyclable, and advanced steel refining processes like vacuum degassing improve properties. Case studies show how automakers are using newer high-strength steels to reduce vehicle weight while improving crash performance.