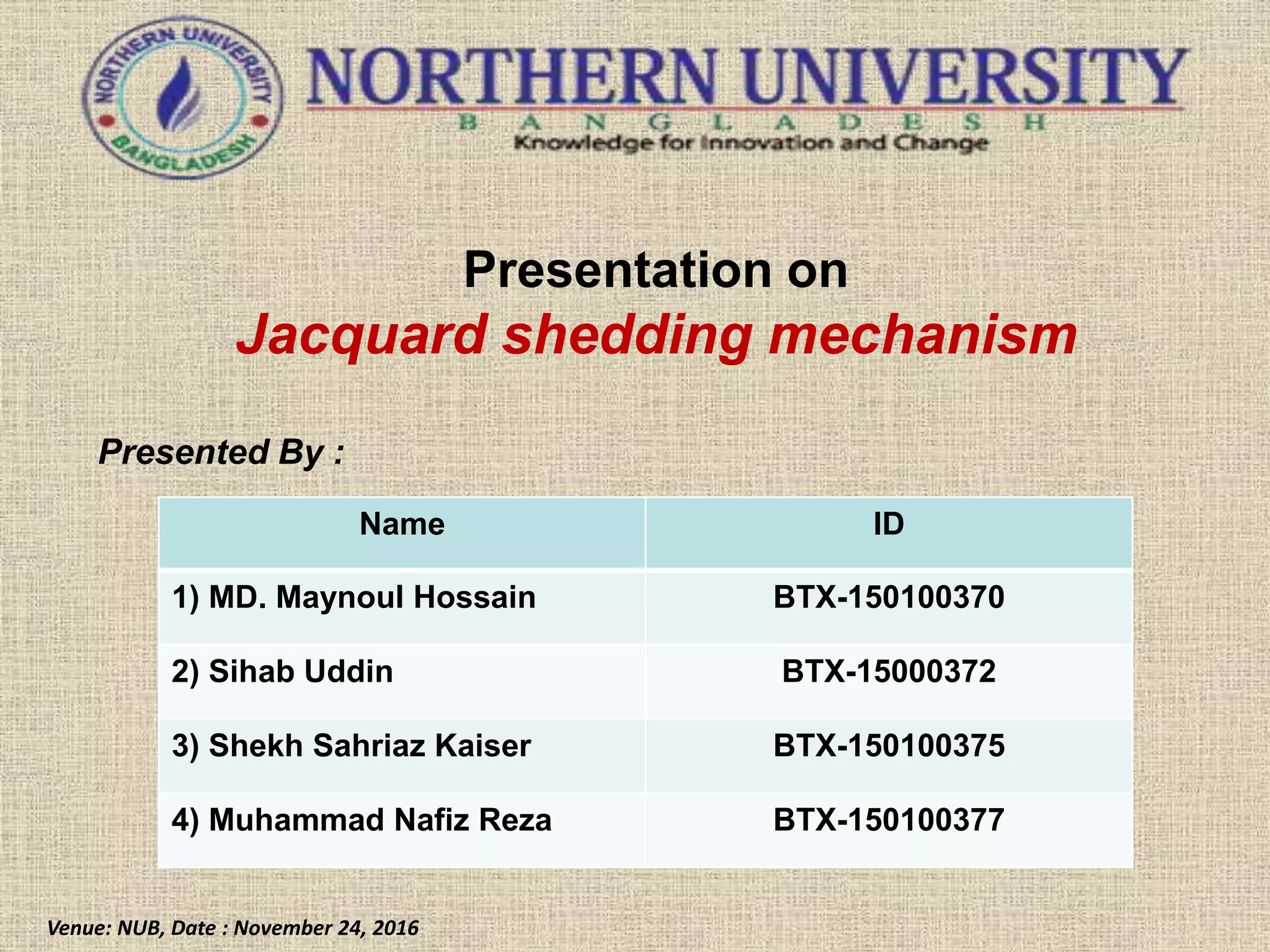

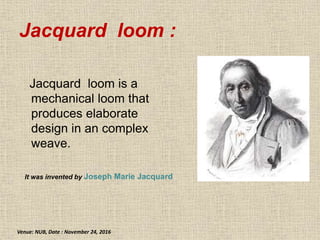

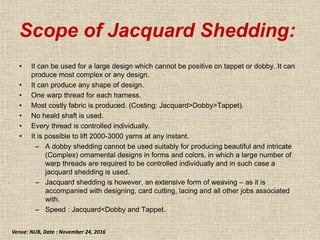

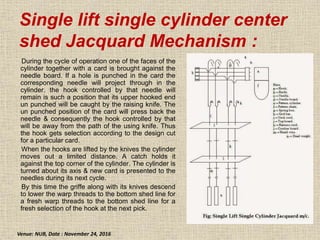

This presentation summarizes the Jacquard shedding mechanism. It introduces the four presenters and provides background on the Jacquard loom, which can produce complex woven designs through individual control of warp threads. The presentation then covers the scope of Jacquard shedding, including its ability to control thousands of yarns and produce intricate designs. It also classifies different types of Jacquard looms based on their lifting capacity, design capacity, shed formation, and other features. Key aspects of the single lift Jacquard mechanism are explained. Advantages and disadvantages of the Jacquard loom conclude the presentation.