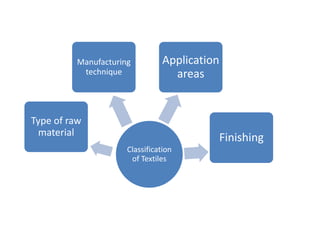

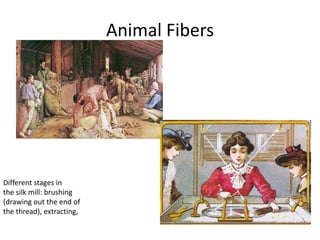

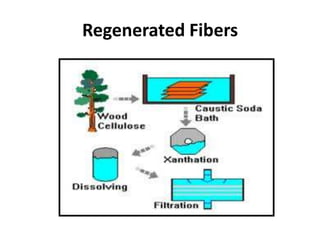

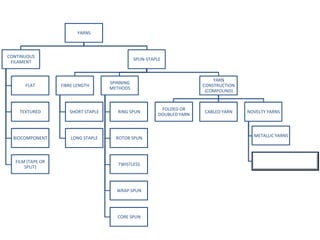

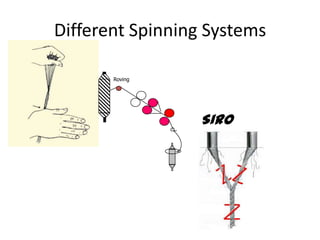

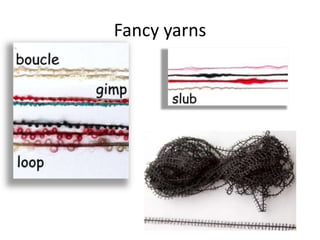

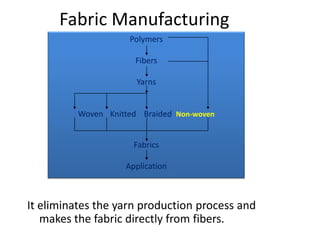

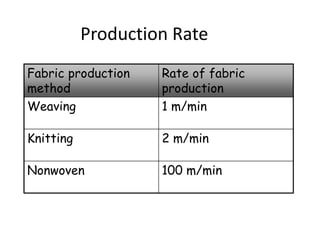

This document provides an overview of textile classification. It discusses the origins and types of fibers, including natural fibers from plants and animals and man-made fibers. The key fiber types are plant bast fibers, animal fibers like silk and wool, and man-made fibers including regenerated cellulose fibers and synthetic fibers. It also covers yarn production methods and the different types of yarns that can be produced. The main methods of fabric formation are discussed as well as different finishing techniques and applications of textiles.