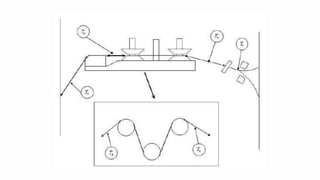

The document discusses different types of pirns and bobbins used in weaving fabrics. It explains that pirns are tapered on one end and used in shuttle looms, while bobbins are uniform in shape and wound back and forth. The process of winding weft yarn onto pirns is described, including how the yarn is tensioned and wound half an inch at a time to create parallel coils. Advantages and disadvantages of using pirns compared to bobbins are provided.