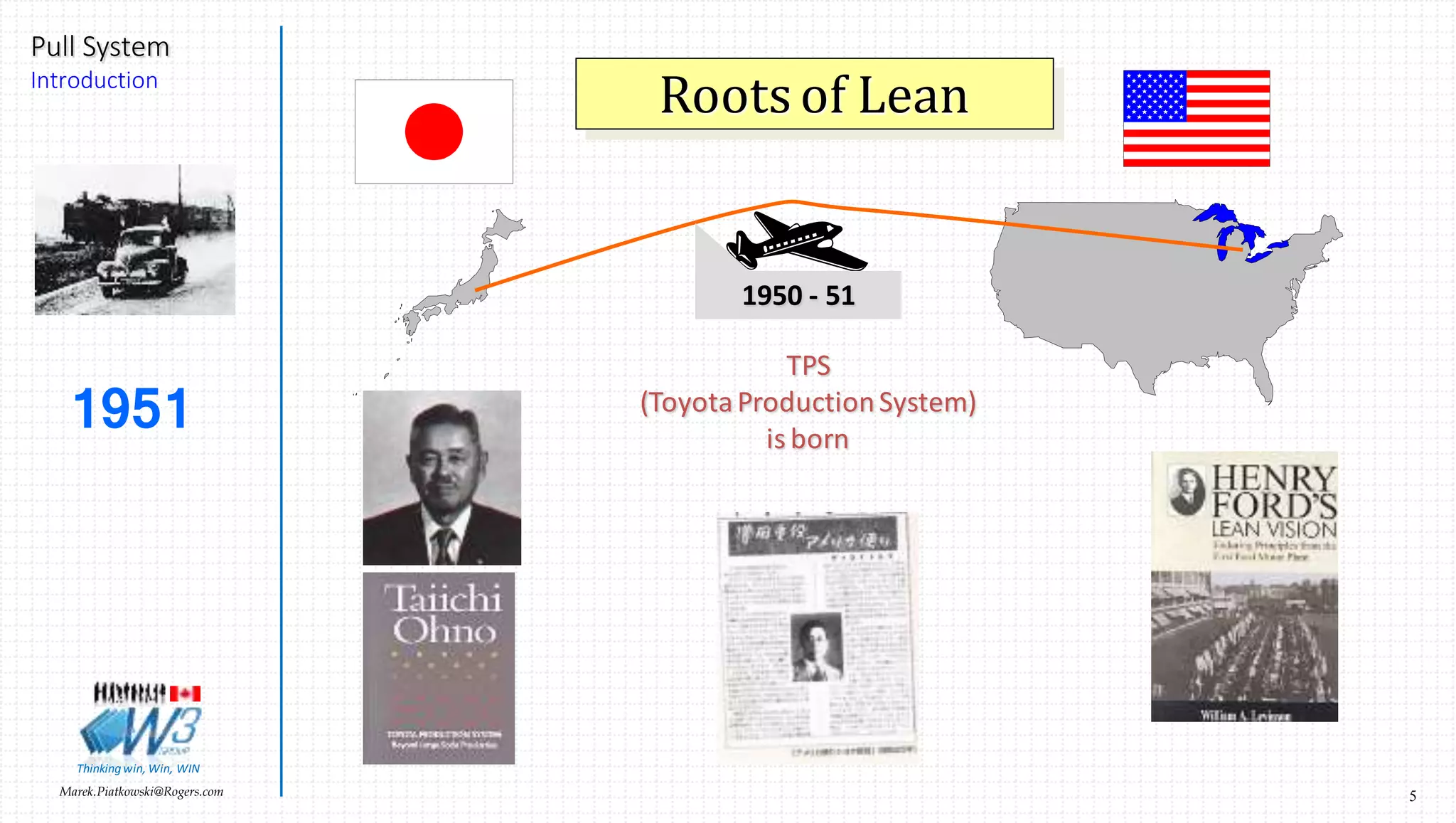

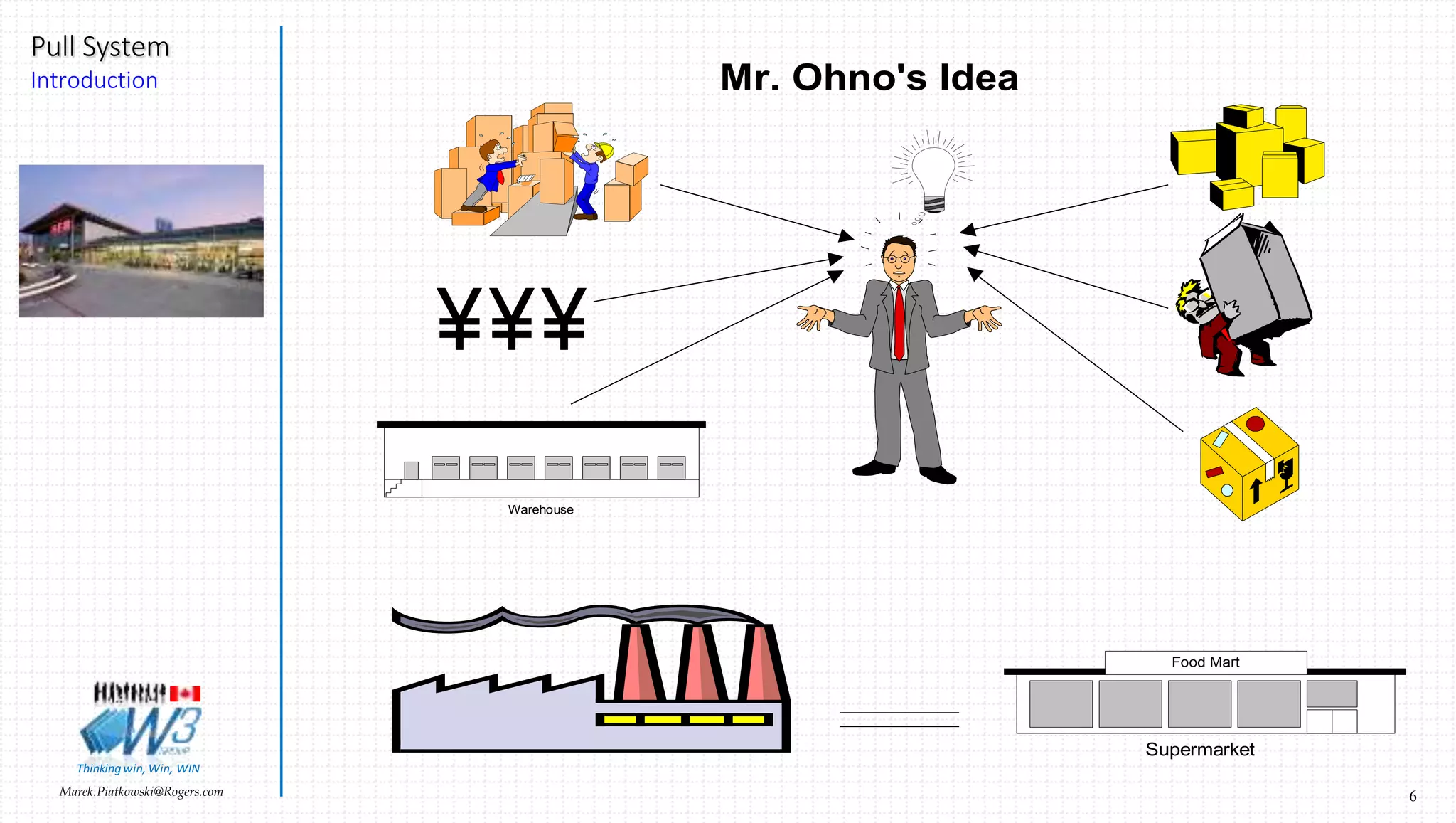

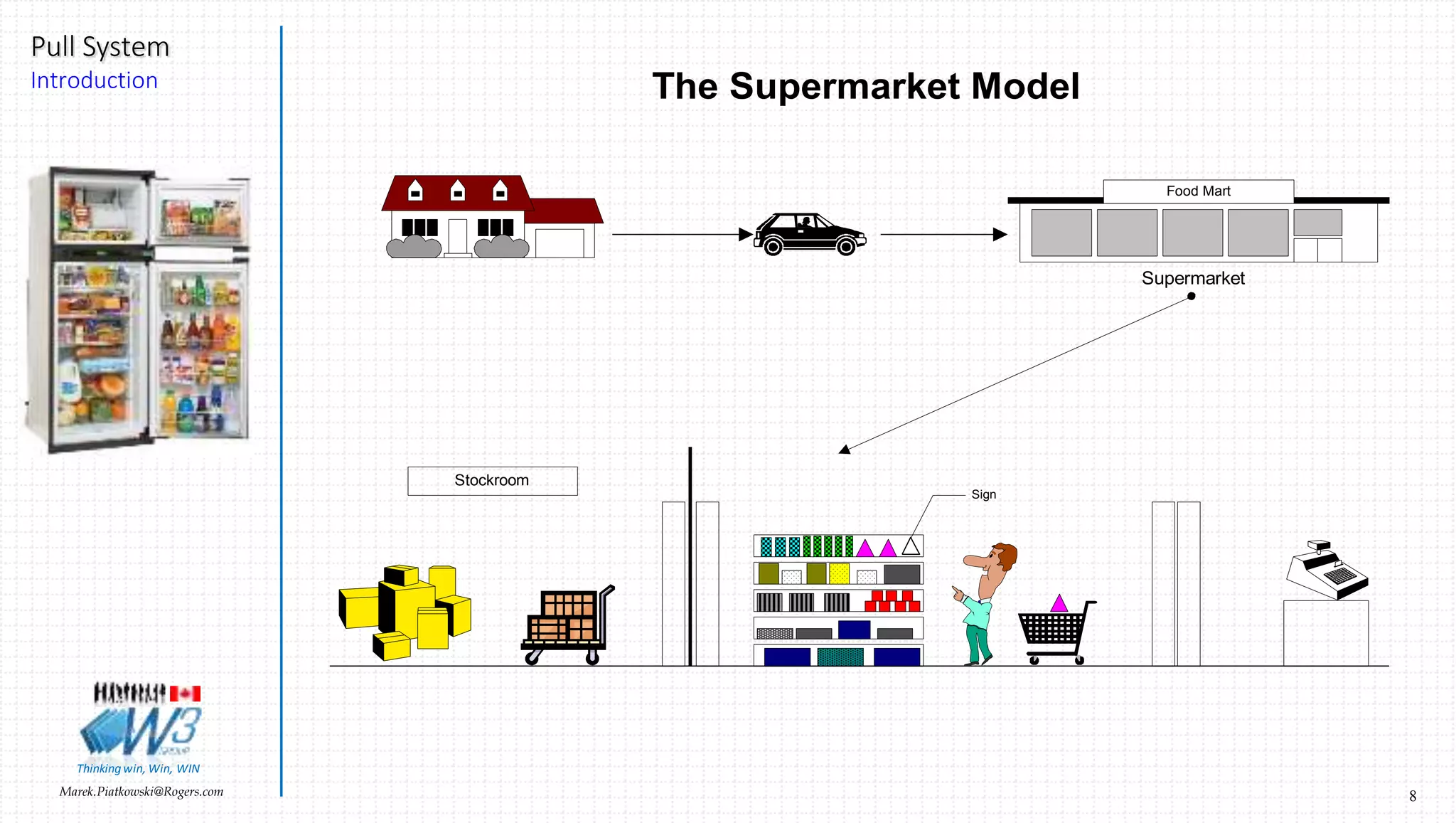

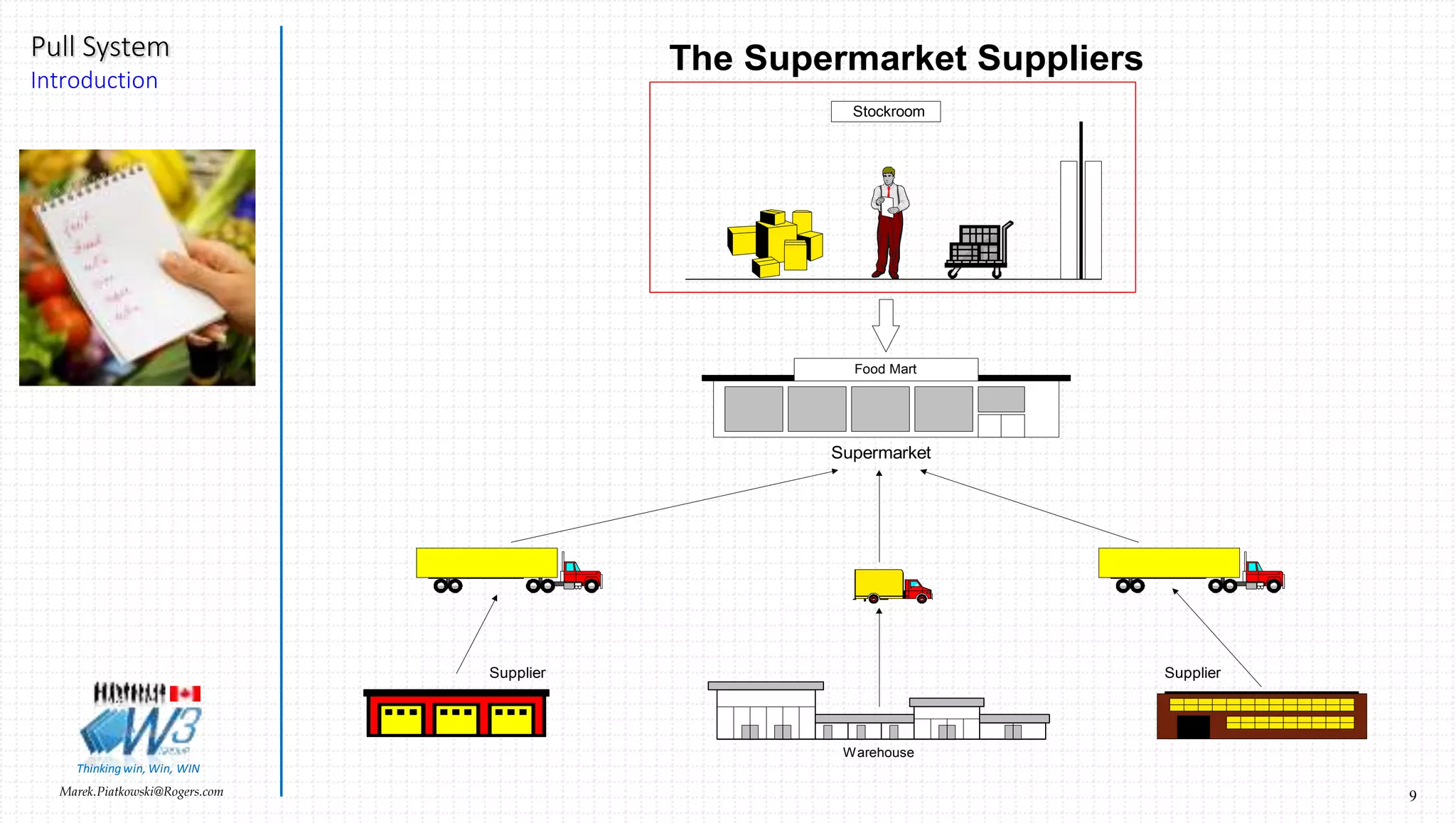

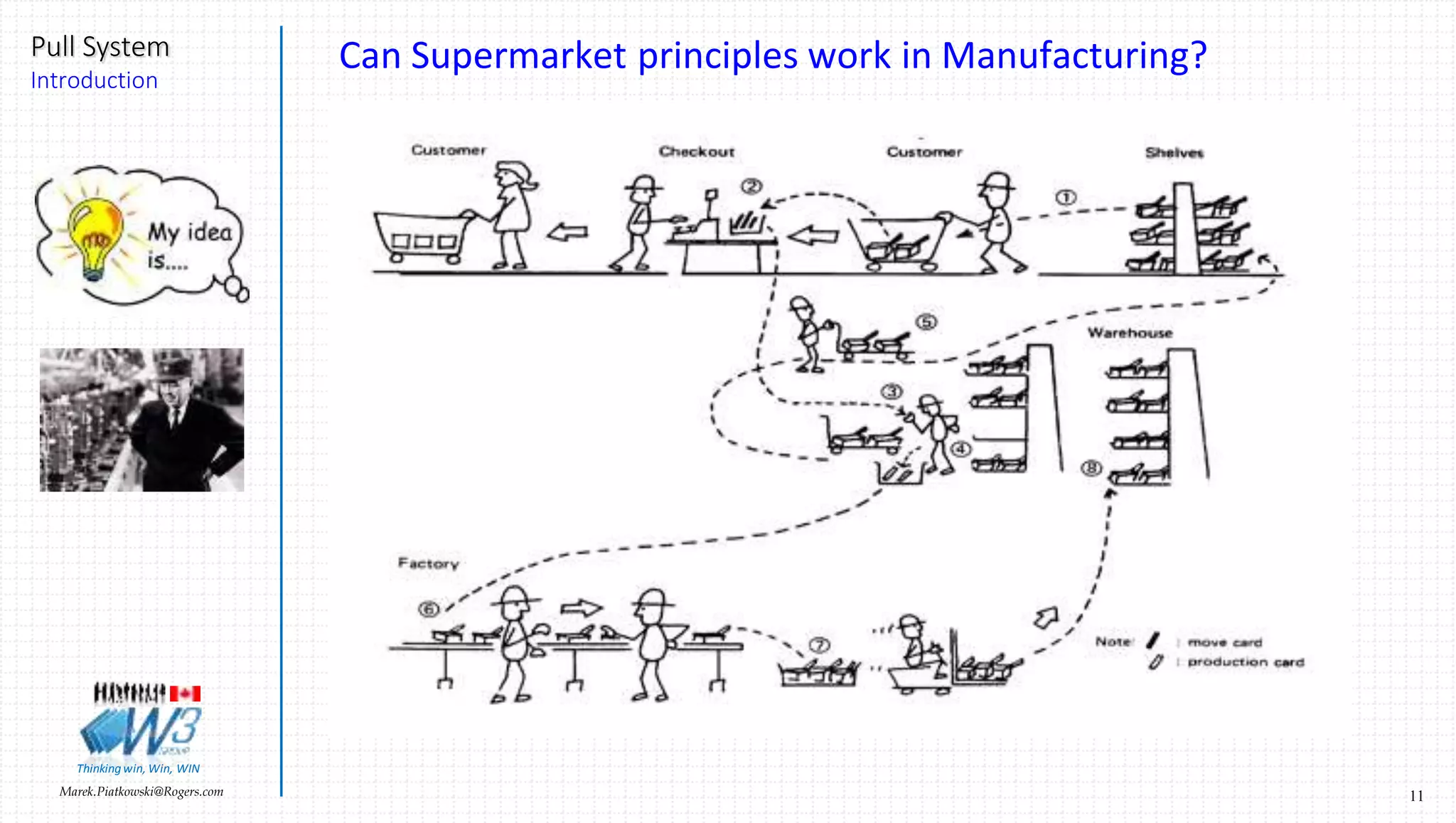

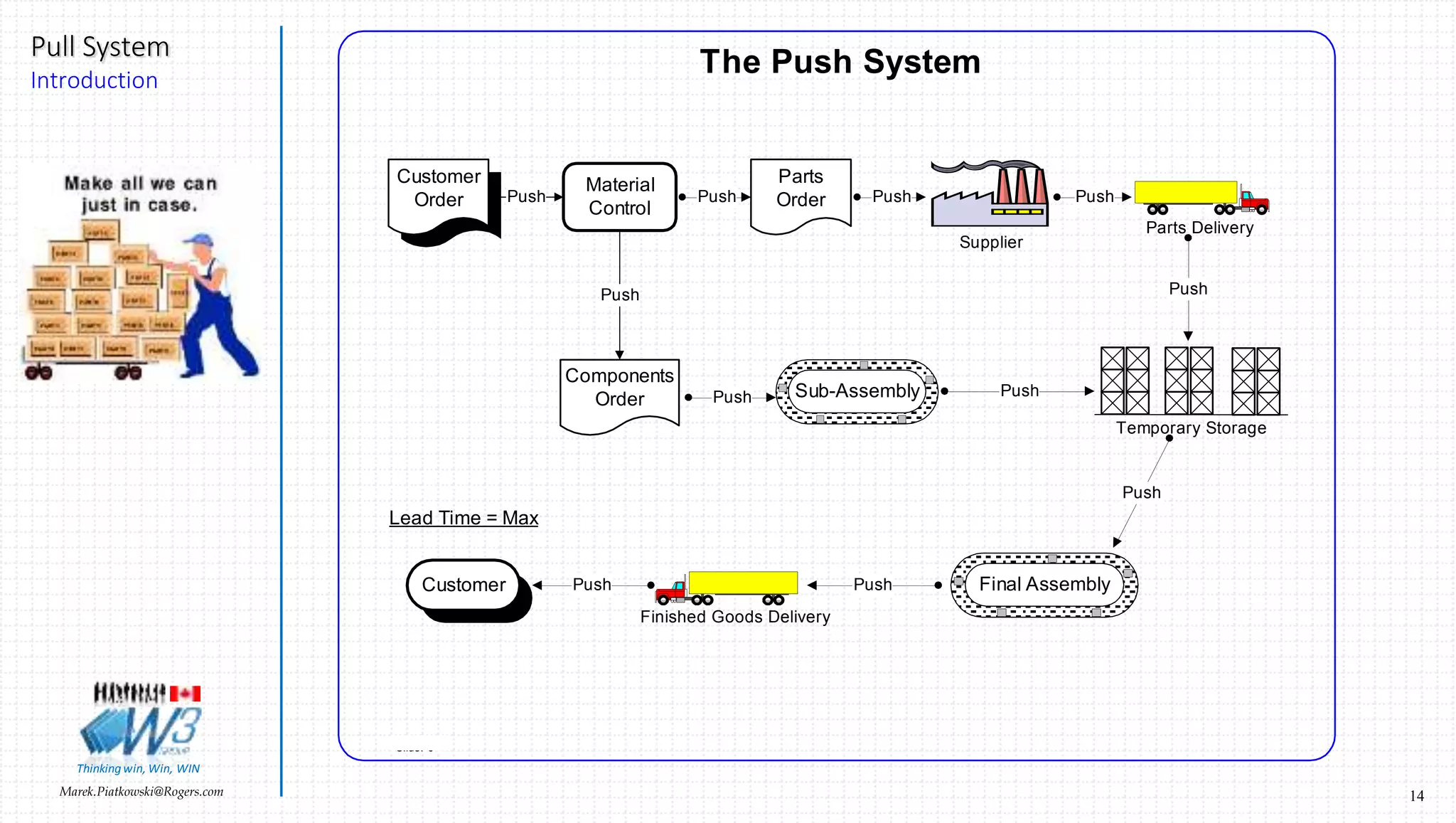

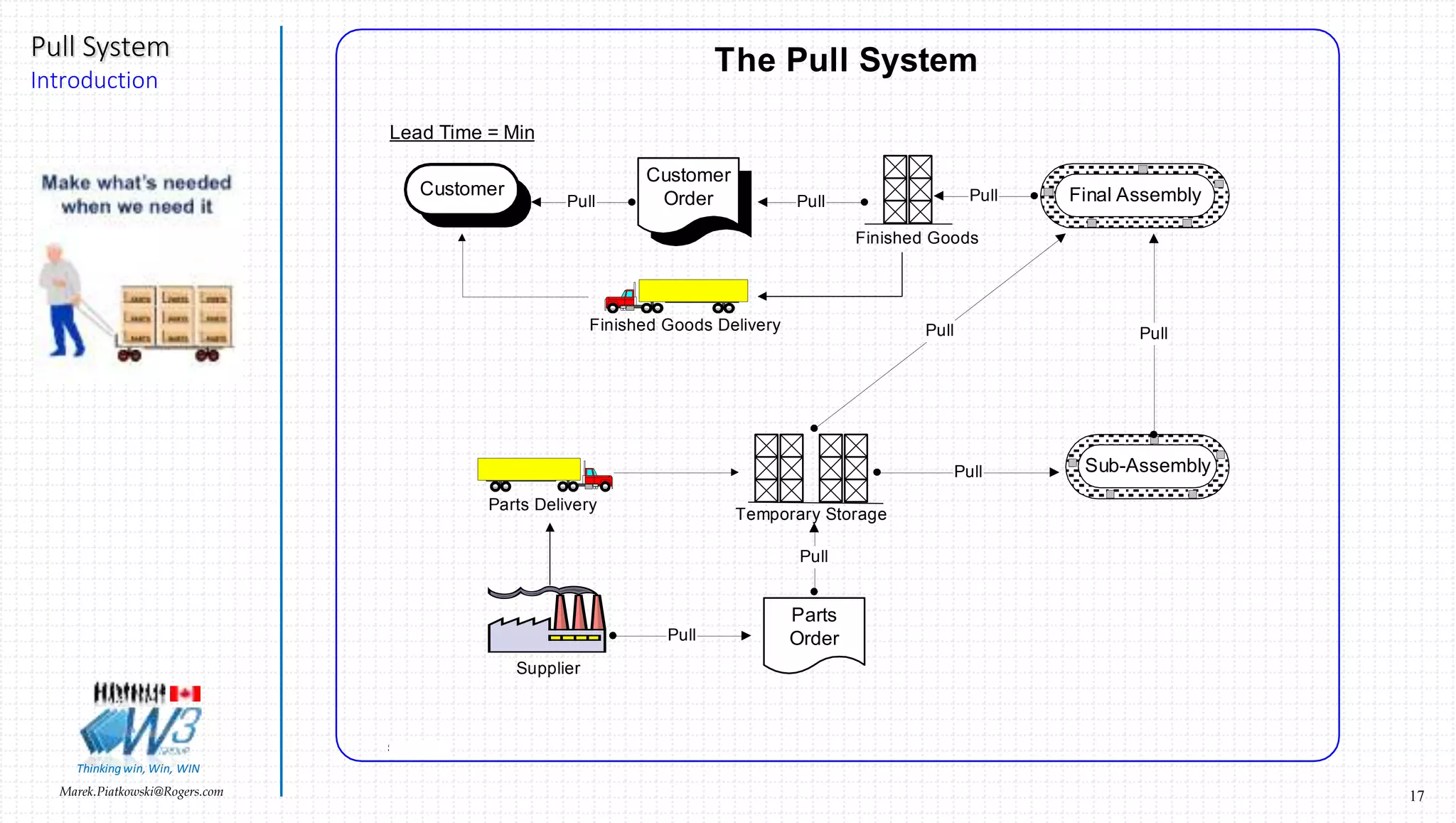

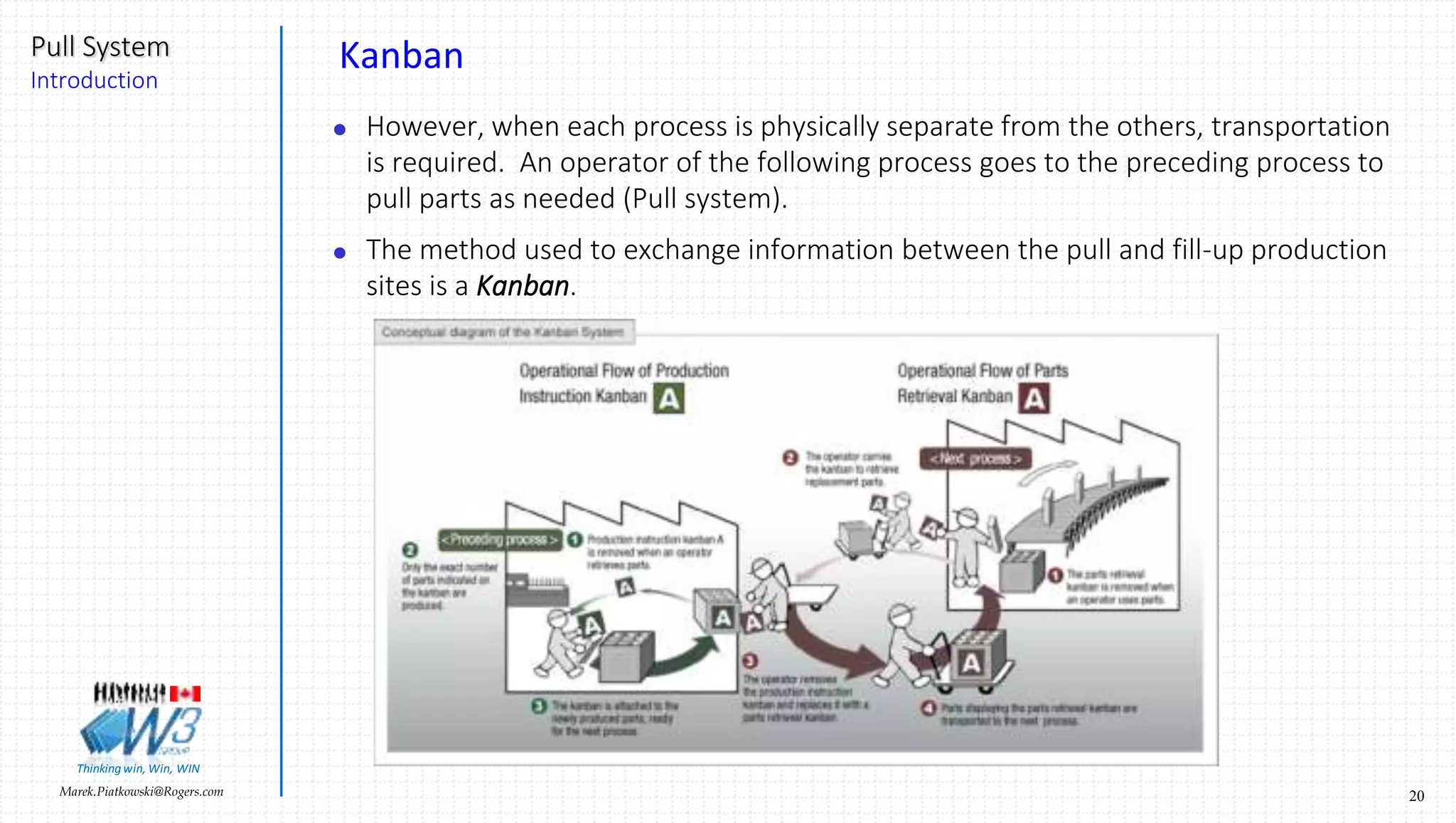

The document introduces the concept of a pull system in manufacturing. It explains that a pull system models production after a supermarket, where the downstream process "pulls" parts as needed from the upstream supplier or process. This contrasts with a traditional push system where parts are produced and pushed to downstream processes based on a schedule. The key advantages of a pull system include only producing what is needed, eliminating overproduction and waste, and ensuring good flow of materials through the process. Kanban cards are also introduced as the mechanism for signaling production requests between processes in a pull system.