The document is a presentation by Marek Piatkowski on supply chain management strategy and materials management strategy based on lean transformation principles. It discusses traditional issues with materials handling, purchasing, inventory management and production practices. It proposes implementing a materials management strategy and organization based on 5 key principles: control and command, inventory control using plan for every part, supermarket-style inventory storage, engineered delivery routes, and production/delivery based on a pull signal. The objectives are to produce what customers want when they want it with minimal waste and inventory costs.

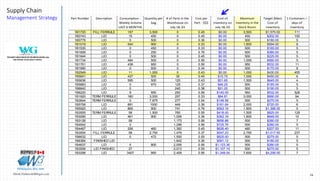

![19Marek.Piatkowski@Rogers.com

Supply Chain

Management Strategy

Thinkingwin, Win, WIN

Komora "411" / Cavity "411"

0

200

400

600

800

1000

1200

1400

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

Zapas[szt]/Stock[pcs]

Supermarket Inventory Reduction](https://image.slidesharecdn.com/1-161120160517/85/Supply-chain-management-strategy-November-2016-19-320.jpg)

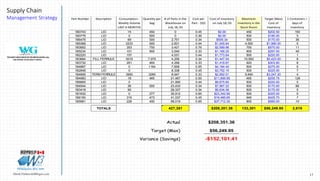

![20Marek.Piatkowski@Rogers.com

Supply Chain

Management Strategy

Thinkingwin, Win, WIN

Komora "321" / Cavity "321"

0

200

400

600

800

1000

1200

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

Zapas[szt]/Stock[pcs]

Supermarket Inventory Reduction](https://image.slidesharecdn.com/1-161120160517/85/Supply-chain-management-strategy-November-2016-20-320.jpg)

![21Marek.Piatkowski@Rogers.com

Supply Chain

Management Strategy

Thinkingwin, Win, WIN

Wszystkie komory / All cavities

0

1000

2000

3000

4000

5000

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29

Zapas[szt]/Stock[pcs]

Charts of inventory in supermarket

> 50% Reduction

of Inventory](https://image.slidesharecdn.com/1-161120160517/85/Supply-chain-management-strategy-November-2016-21-320.jpg)