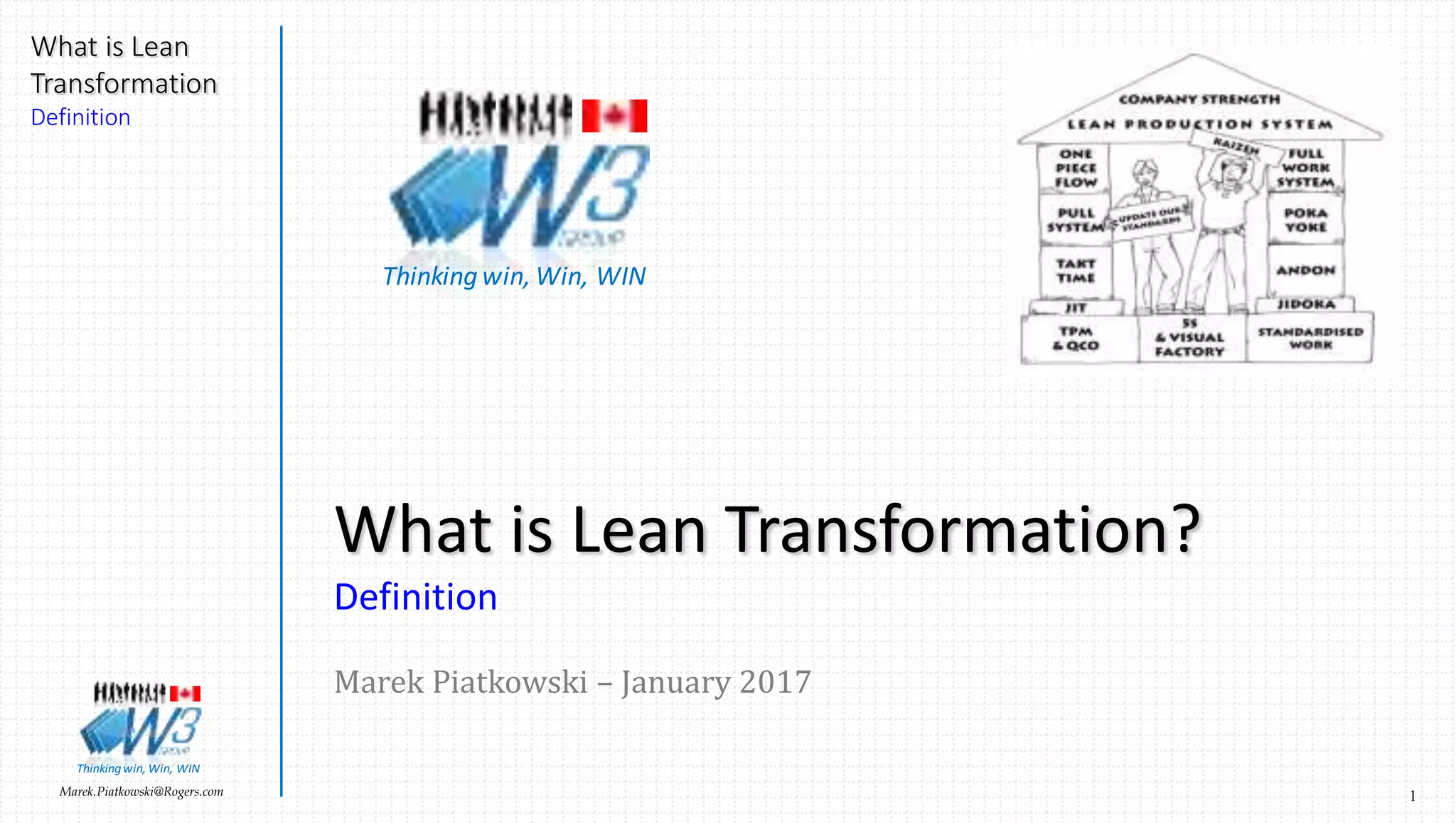

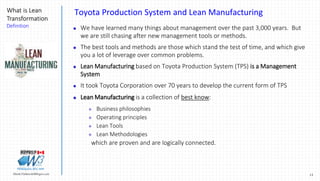

The document defines Lean Transformation as a systematic methodology for implementing rapid process changes and improvements by eliminating waste. It is based on principles from the Toyota Production System including putting customers first, treating people as the most valuable resource, embracing continuous improvement (kaizen), and focusing on the shop floor (gemba). Lean Transformation utilizes business philosophies, operating principles, Lean tools and methodologies to guide companies towards higher profits, success, stability and growth. The document traces the historical development of management systems and Lean thinking over centuries, from early Venetian shipyards to Toyota.