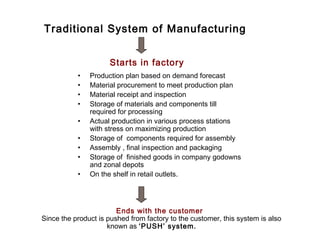

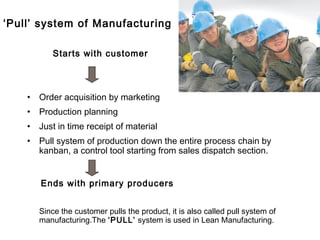

The document describes the traditional 'push' system of manufacturing and its weaknesses compared to the 'pull' system. The traditional system starts in the factory with production based on demand forecasts, involves storage of materials and components, and ends with finished goods in storage until purchased by customers. This pushes products from the factory to customers. In contrast, the 'pull' system starts with customer orders and uses a pull system of production down the process chain triggered by customer demand. The key principles of the 'pull' system emphasize minimizing waste and maximizing flow, utilization, flexibility, and communication.