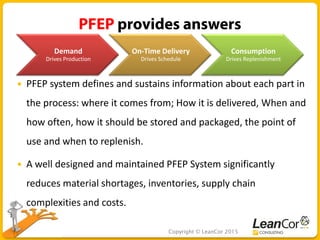

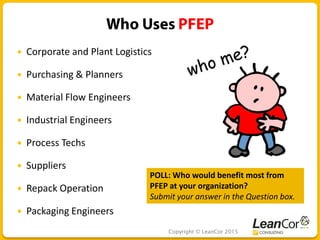

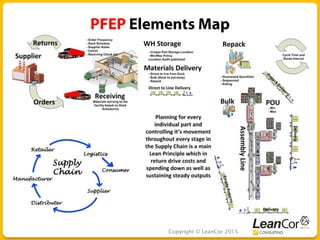

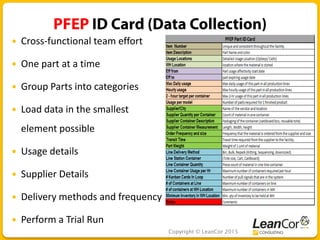

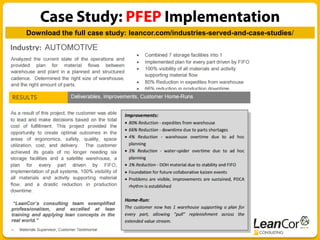

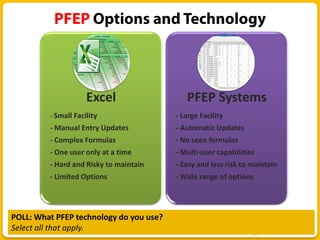

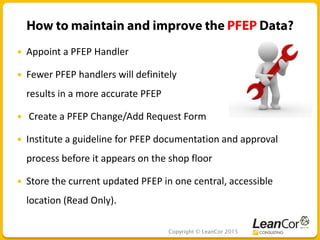

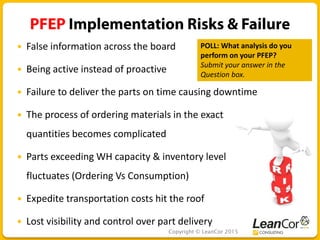

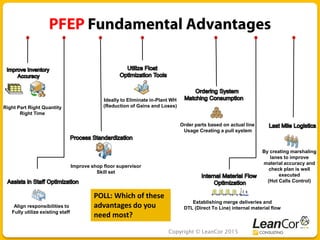

The document discusses the optimization of supply chain processes through the implementation of a Plan for Every Part (PFEP) system, which enhances material flow and reduces costs. It emphasizes the importance of standardization, education, and continuous improvement in supply chain management. LeanCor provides training and tailored supply chain solutions to improve operational excellence across various industries.