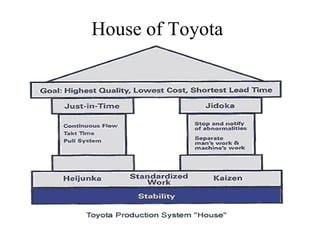

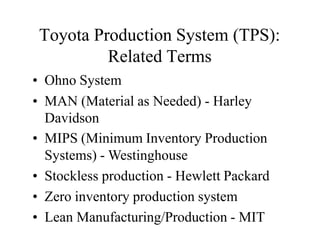

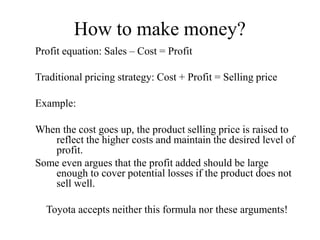

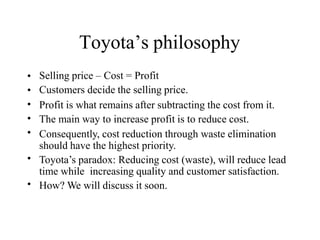

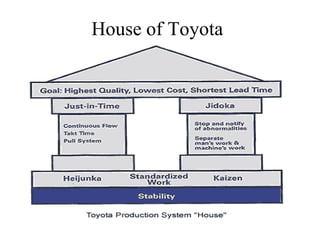

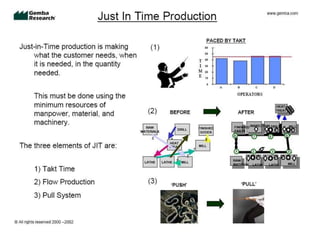

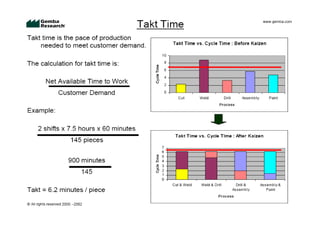

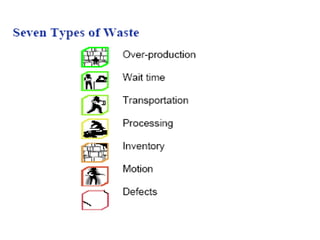

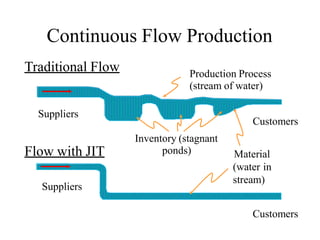

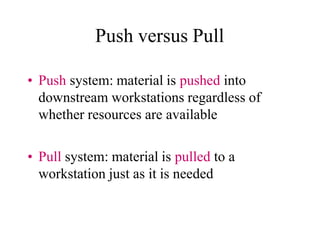

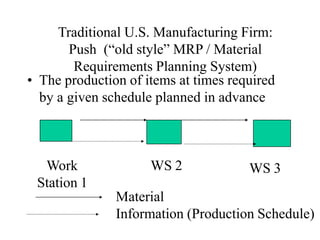

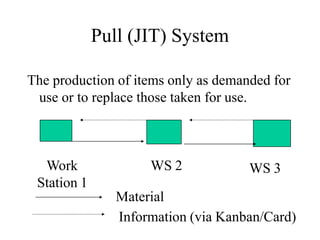

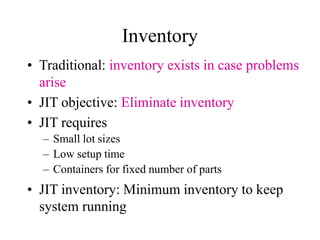

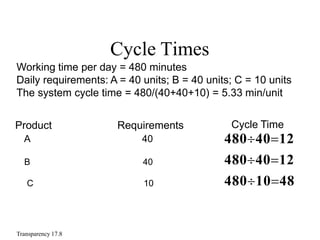

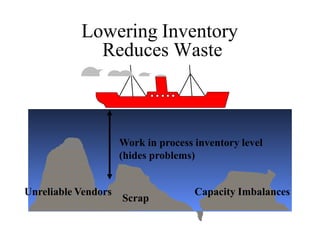

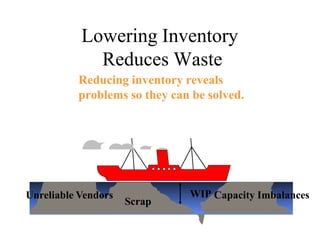

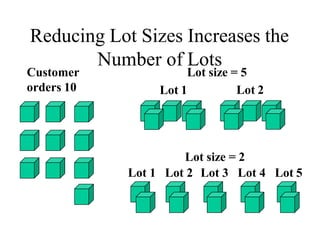

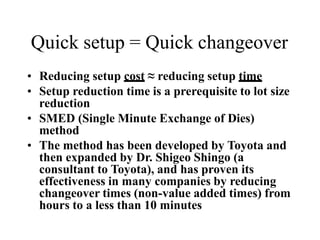

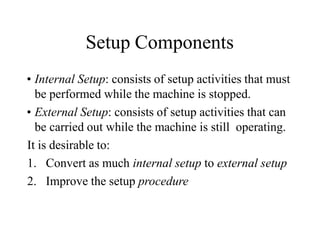

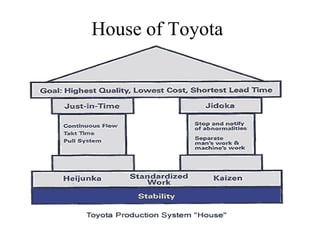

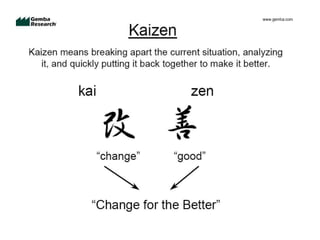

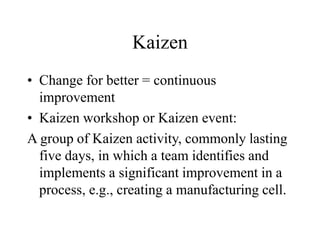

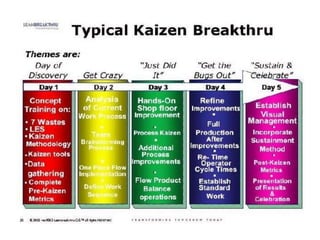

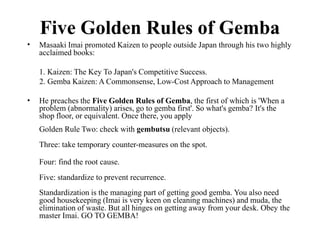

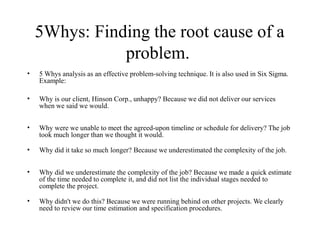

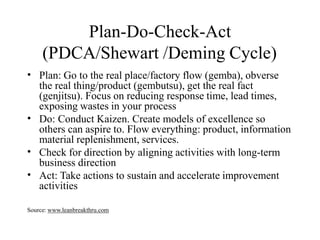

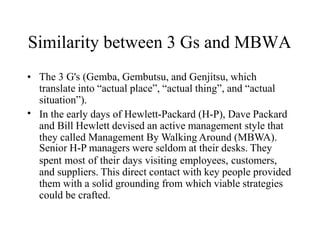

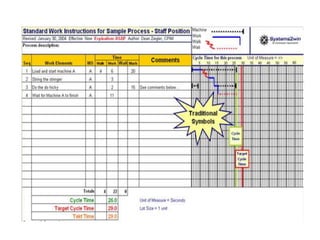

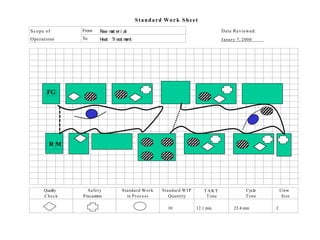

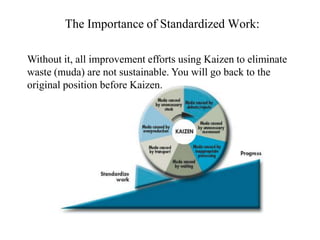

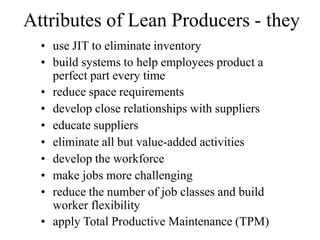

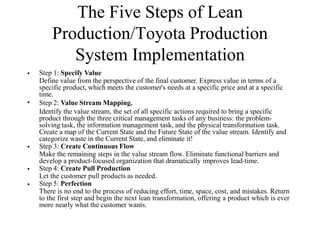

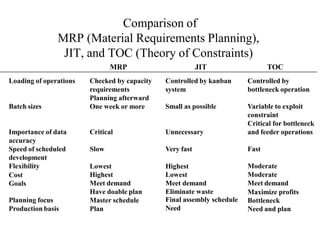

The document outlines the history and principles of the Toyota Production System (TPS), including its two main pillars: Just-in-Time (JIT) and Jidoka (autonomation). It describes key figures involved in its development, the concepts of waste reduction, continuous improvement through Kaizen, and methodologies like the 5 Whys and Plan-Do-Check-Act cycles. TPS has significantly influenced manufacturing practices worldwide, promoting effective resource management and quality assurance.