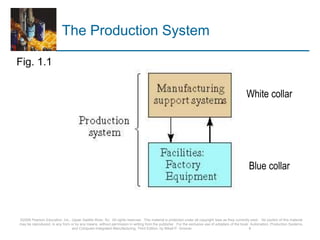

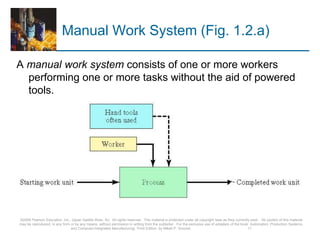

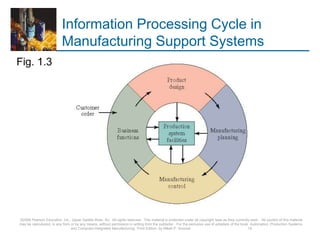

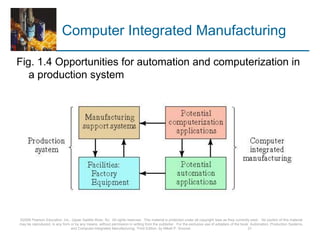

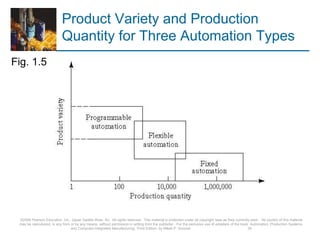

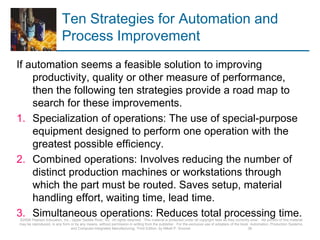

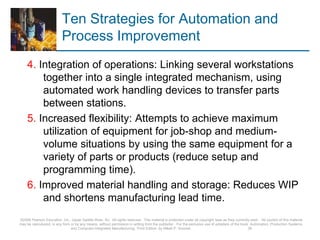

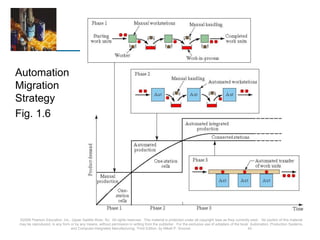

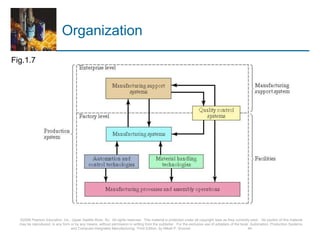

The document provides an overview of computer-integrated manufacturing, discussing the evolution of manufacturing processes from manual labor to automation and the realities of modern manufacturing, including globalization and quality expectations. It highlights the importance of manufacturing systems, support systems, and various automation technologies essential for operational efficiency and competitive advantage. Specific categories of automation such as fixed, programmable, and flexible automation are also described, emphasizing their roles in contemporary manufacturing environments.