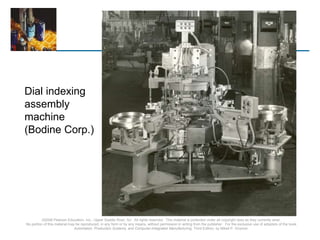

This document discusses automated assembly systems. It begins by defining automated assembly as using mechanized devices to perform assembly tasks in an automated line or cell. Automated assembly is most suitable for products made in large quantities with stable designs. Common assembly configurations include in-line machines with sequential stations, dial indexing machines with circular work flow, and single-station cells often using robots. The document describes various automated assembly processes and parts delivery systems used at workstations, such as vibratory bowl feeders.