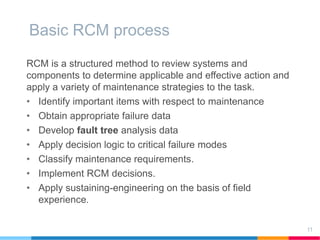

Reliability Centered Maintenance (RCM) is a systematic approach designed to ensure that physical facilities meet their functions efficiently within their operating context, focusing on preventive maintenance for failure modes. Key components of RCM include reactive, preventive, predictive, and proactive maintenance, each serving distinct roles in minimizing failures and optimizing maintenance strategies. The document outlines the goals and principles of RCM, emphasizing safety, cost-effectiveness, and continuous improvement in maintenance practices.