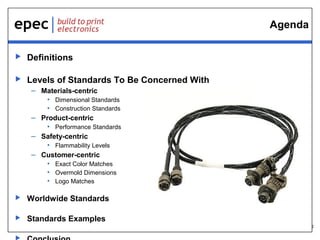

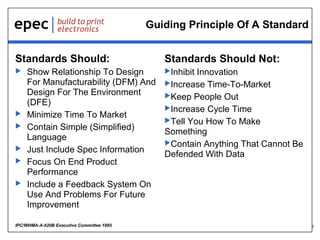

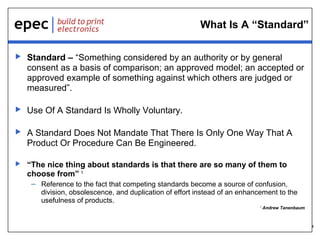

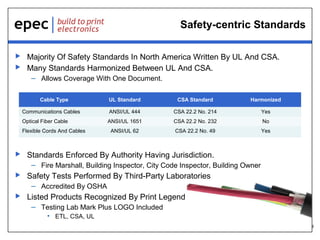

The document discusses industry standards and how they impact cable assembly designs. It defines various types of standards including materials-centric, product-centric, safety-centric, and customer-centric standards. It also discusses key standards organizations, different types of standards documents, and examples of performance and safety standards that are important for cable assemblies. The document aims to provide an overview of the many industry standards that must be considered in cable assembly design.