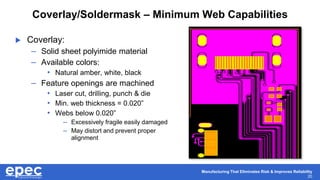

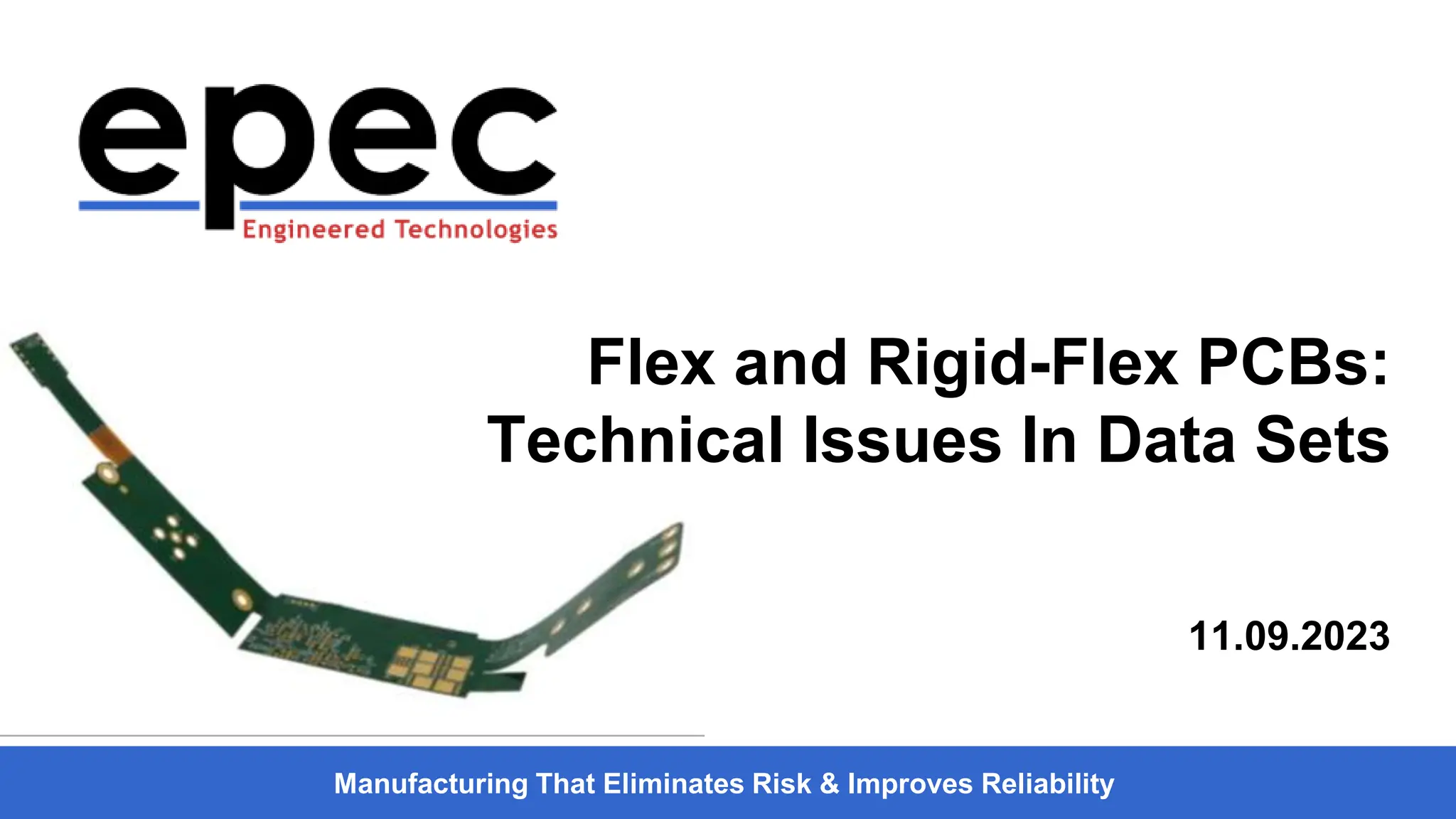

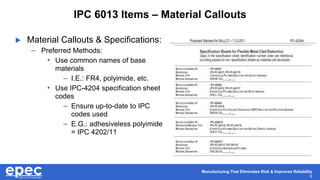

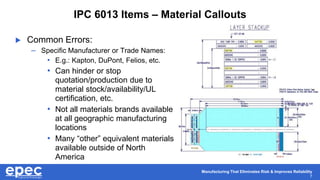

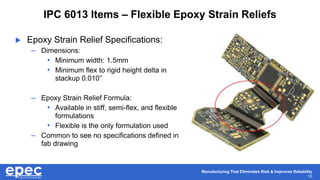

The document discusses the technical challenges in designing flex and rigid-flex printed circuit boards (PCBs), highlighting key issues like IPC 6013 requirements, mechanical specifications, and material callouts. It emphasizes the importance of accurate specifications to avoid delays or redesigns in manufacturing, and addresses common errors that can hinder production, such as incorrect callouts and design practices. Furthermore, it covers the use of combination coverlay and soldermask for high-density components and the implications of brand-specific material requirements on supply chains.

![Manufacturing That Eliminates Risk & Improves Reliability

11

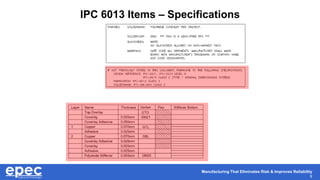

IPC 6013 Items – Plated Through Holes & Vias

Plating Requirements

– Per IPC-6013 for Flex & Rigid-Flex

• 2-layer flex

– Average 12um [472uin], Minimum 10um [394uin]

• 3+layer rigid-flex and flex boards

– Average 25um [984uin], Minimum 20um [787uin]

– Common Errors:

• Copper thickness callout for incorrect layer count

• Callouts for IPC-6012 plating](https://image.slidesharecdn.com/flexandrigid-flexpcbs-technicalissuesindatasets-231109190607-1429811e/85/Flex-and-Rigid-Flex-PCBs-Technical-Issues-In-Data-Sets-11-320.jpg)