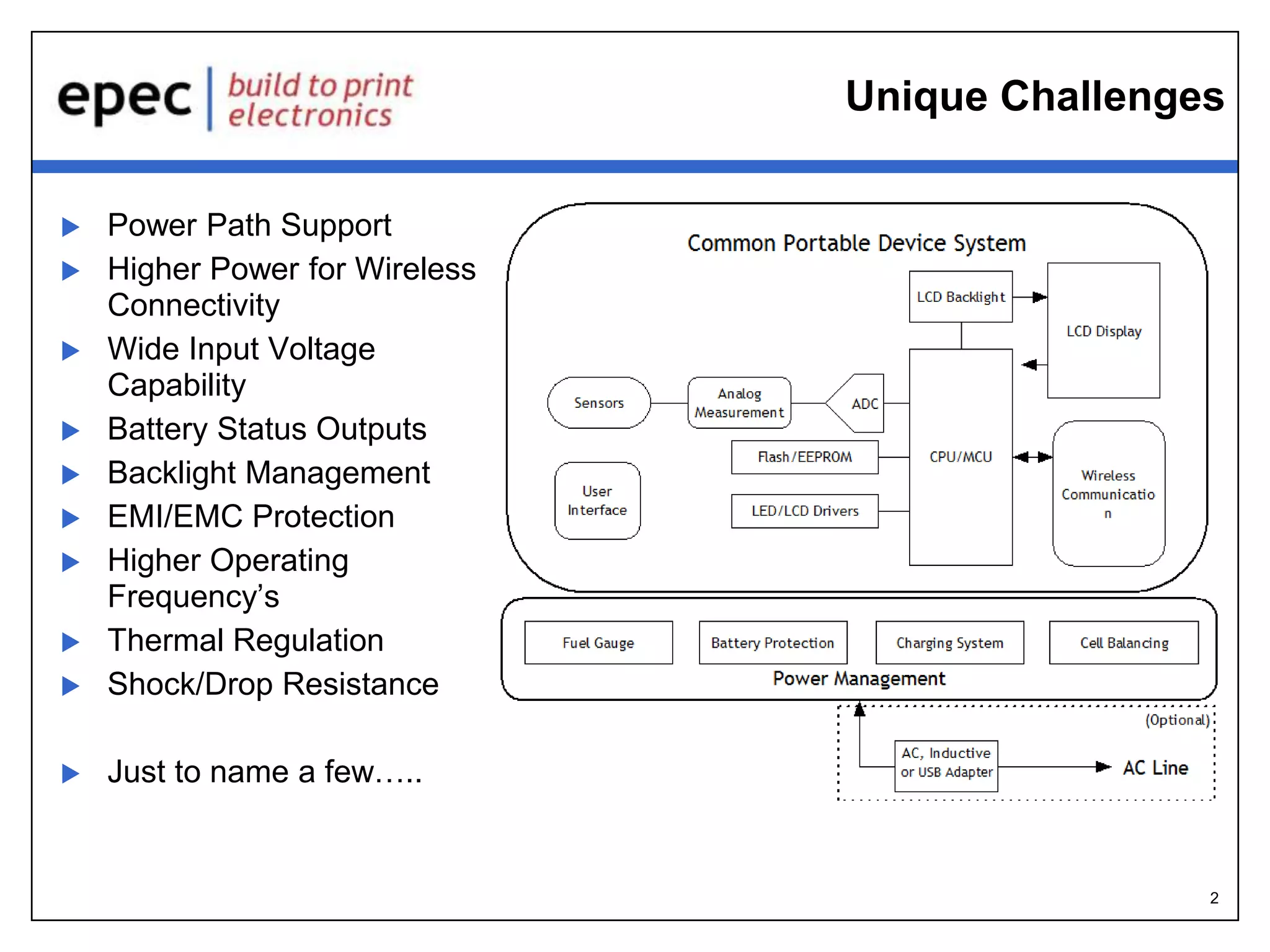

The document outlines Epec Engineered Technologies' extensive expertise in battery power management for portable devices, highlighting unique challenges and specific solutions for increasing efficiency and battery life. It details their capabilities in design, manufacturing, and regulatory compliance, along with their investment in global operations to enhance quality and reduce lead times. Furthermore, Epec emphasizes their commitment to customer-specific needs through tailored inventory management and technical support.