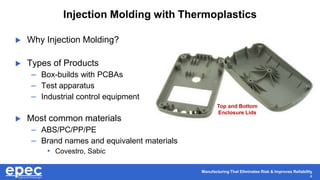

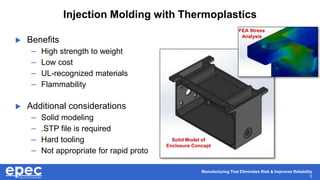

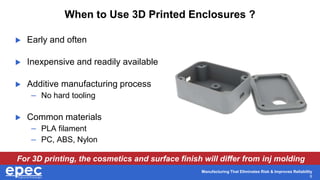

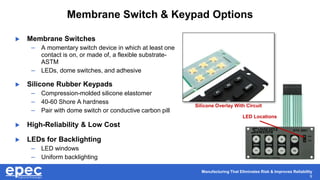

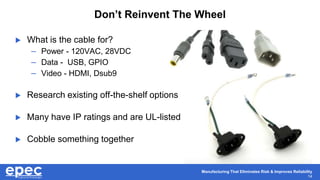

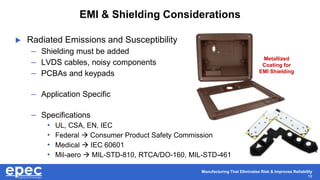

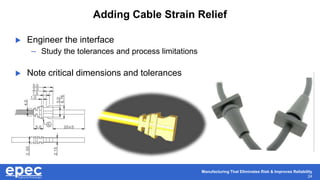

The document discusses manufacturing processes for creating custom injection-molded enclosures with a focus on keypads and cabling solutions to enhance reliability and reduce risks. It provides insights into material selection, prototyping, ingress protection, and design considerations for electronic assemblies. Key recommendations include the use of 3D printing for prototyping, understanding certifications, and the importance of guarding against environmental ingress.