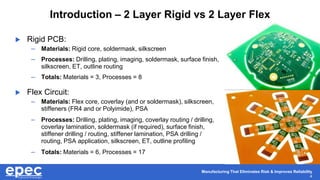

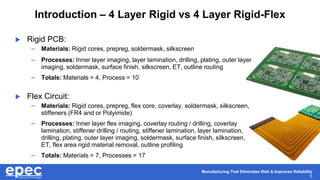

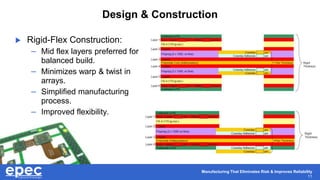

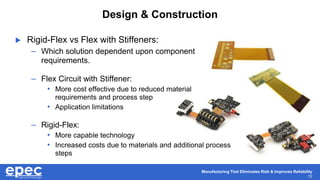

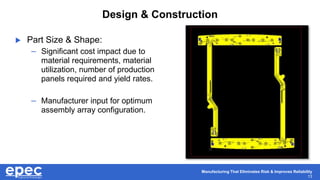

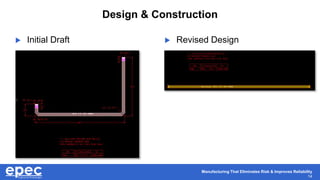

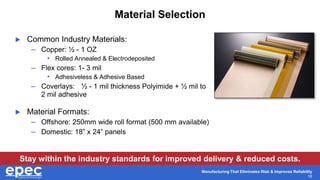

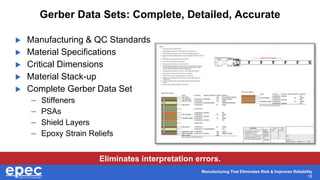

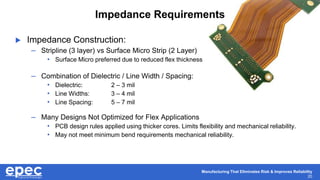

The document outlines the complexities of manufacturing flex and rigid-flex printed circuit boards (PCBs), emphasizing the need for streamlining designs to reduce costs and enhance reliability. It discusses the various materials and processes involved, the importance of Design for Manufacturability (DFM), and the role of early manufacturer input in optimizing designs. Key features such as impedance requirements, additional elements like stiffeners and shield layers, and their impact on manufacturing efficiency are also highlighted.