Custom battery pack design plays a crucial role in ensuring optimal performance, longevity, and safety across a wide range of applications. Whether you're designing for high-power industrial systems, lightweight consumer electronics, or mission-critical medical devices, every aspect of battery selection and integration impacts efficiency, reliability, and compliance.

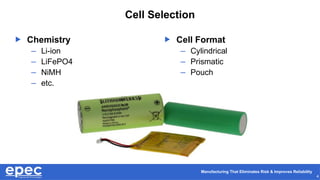

In this webinar, we cover key design factors, including how different battery chemistries, such as Li-Ion, LiFePO4, and NiMH affect performance, safety, and cycle life. We’ll discuss the importance of balancing capacity and voltage to meet power demands while maximizing efficiency. Charging configurations also play a major role, whether prioritizing fast charging or long-term battery longevity. Additionally, environmental conditions, including temperature extremes and space constraints, influence battery performance, requiring careful design considerations.

For more information on our custom battery pack solutions, visit https://www.epectec.com/batteries/.