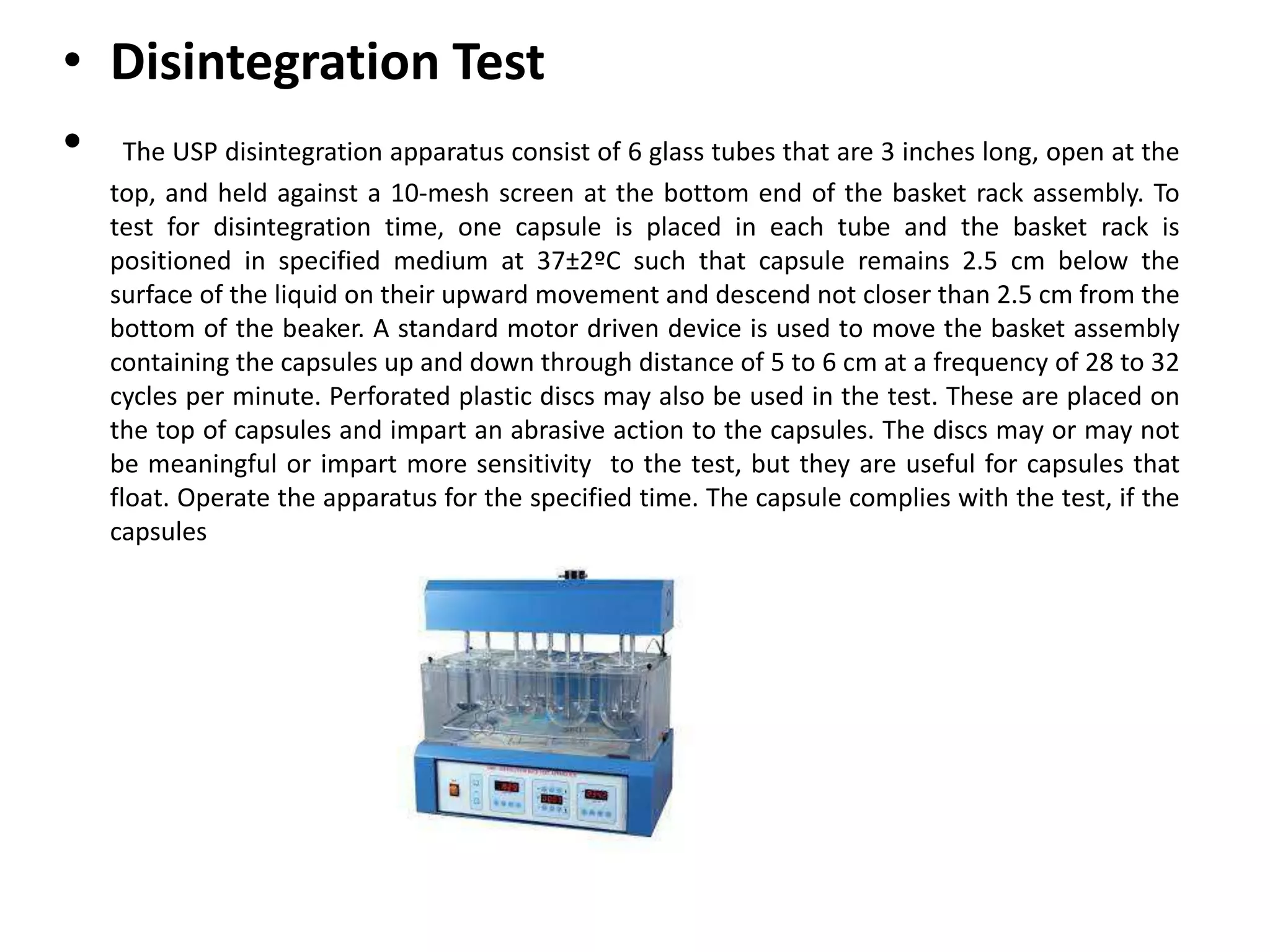

This document discusses quality control tests for pharmaceutical capsules that are performed during the manufacturing process (IPQC tests) and on finished products (FPQC tests). It provides details on various physical parameters tested by IPQC like temperature, humidity, weight variation. FPQC tests include assays, dissolution testing, stability testing, and ensuring uniform drug content between capsules. The document outlines specific test methods and acceptance criteria from pharmacopeias for tests like disintegration, dissolution and content uniformity. It emphasizes that quality testing helps ensure capsules meet regulatory standards and provides maximum safety for human health.