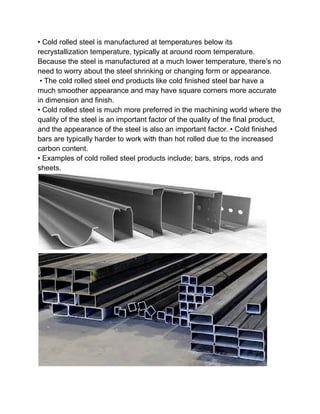

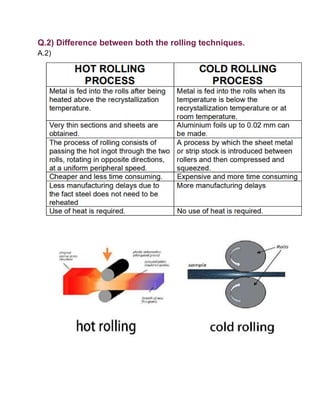

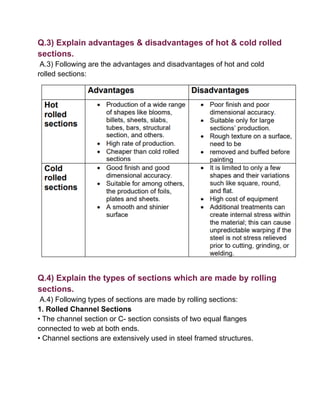

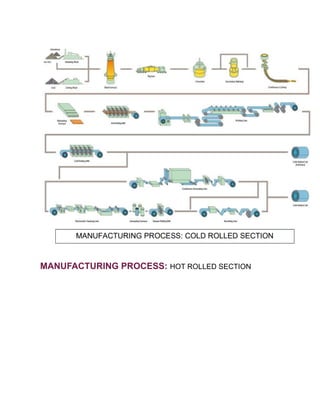

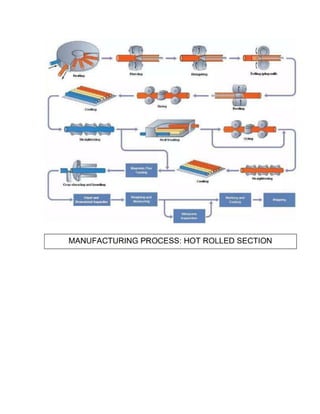

The document discusses hot rolled and cold rolled steel sections. Hot rolled sections involve shaping steel above its recrystallization temperature using large rollers to deform hot metal slabs. This allows large sizes but with less dimensional control. Cold rolled sections further process hot rolled steel below the recrystallization temperature through annealing and tempering rolls. This increases strength, hardness and dimensional accuracy but requires more rolling cycles. The document provides examples of sections produced by both methods like channels, angles and bars, and discusses their advantages and uses.