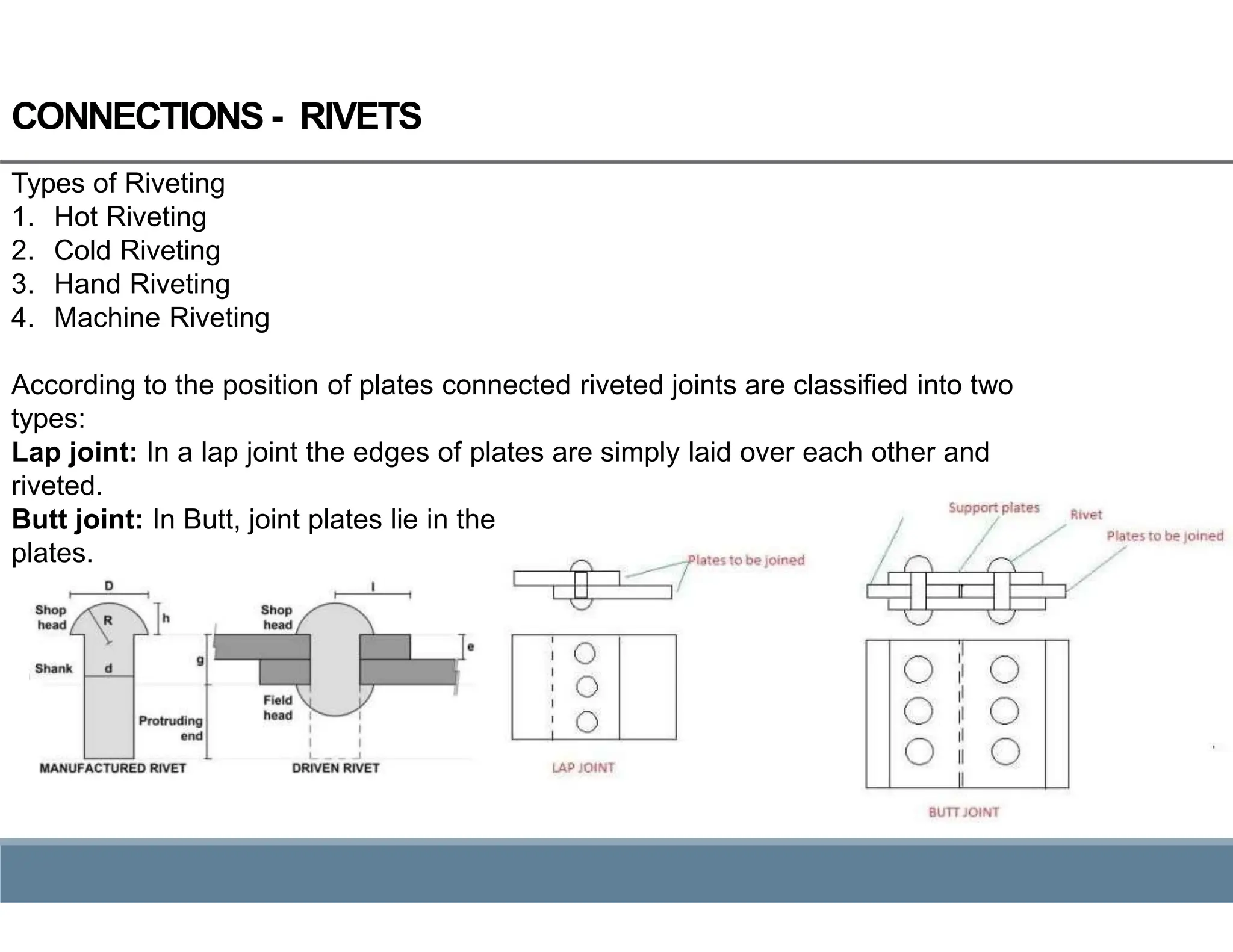

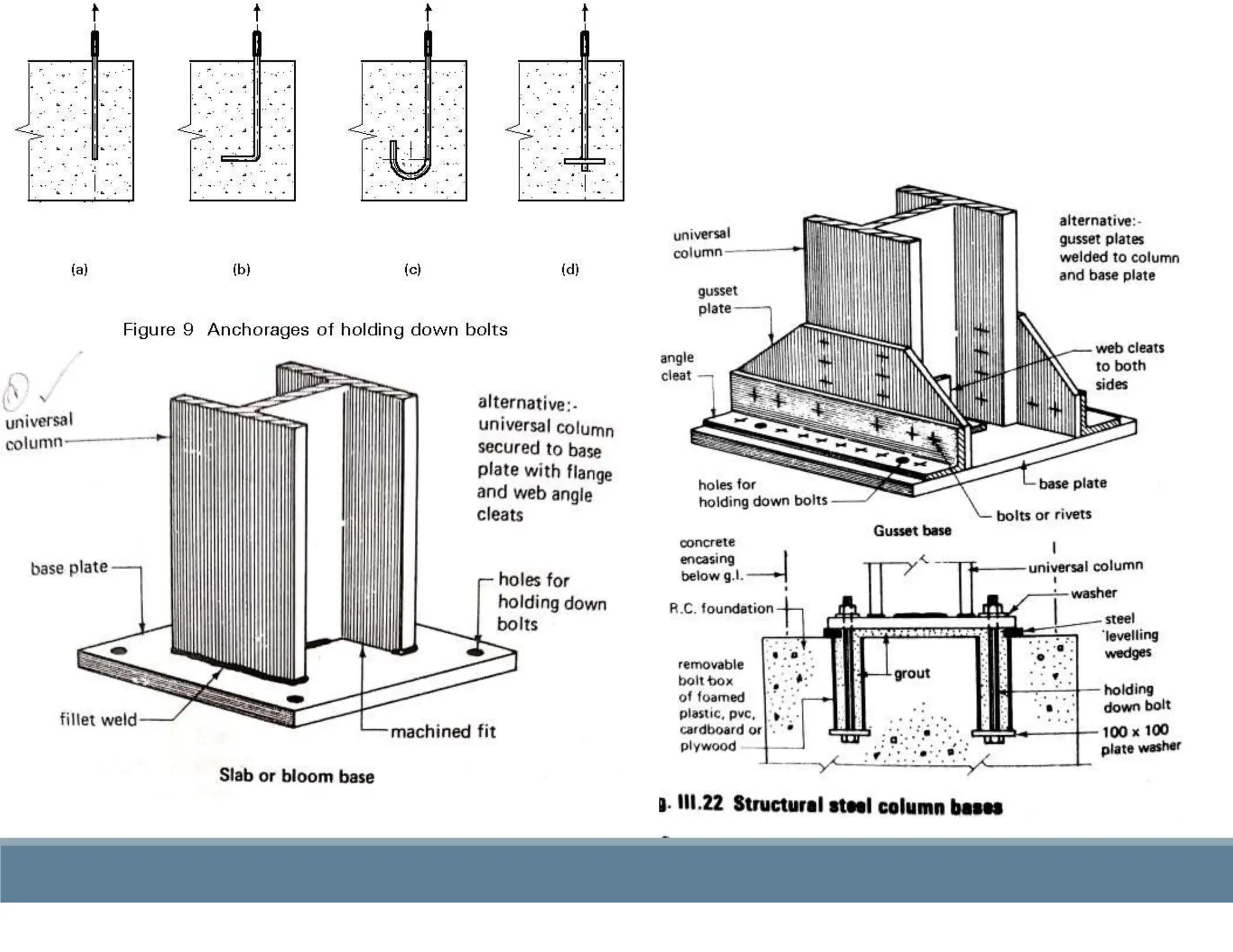

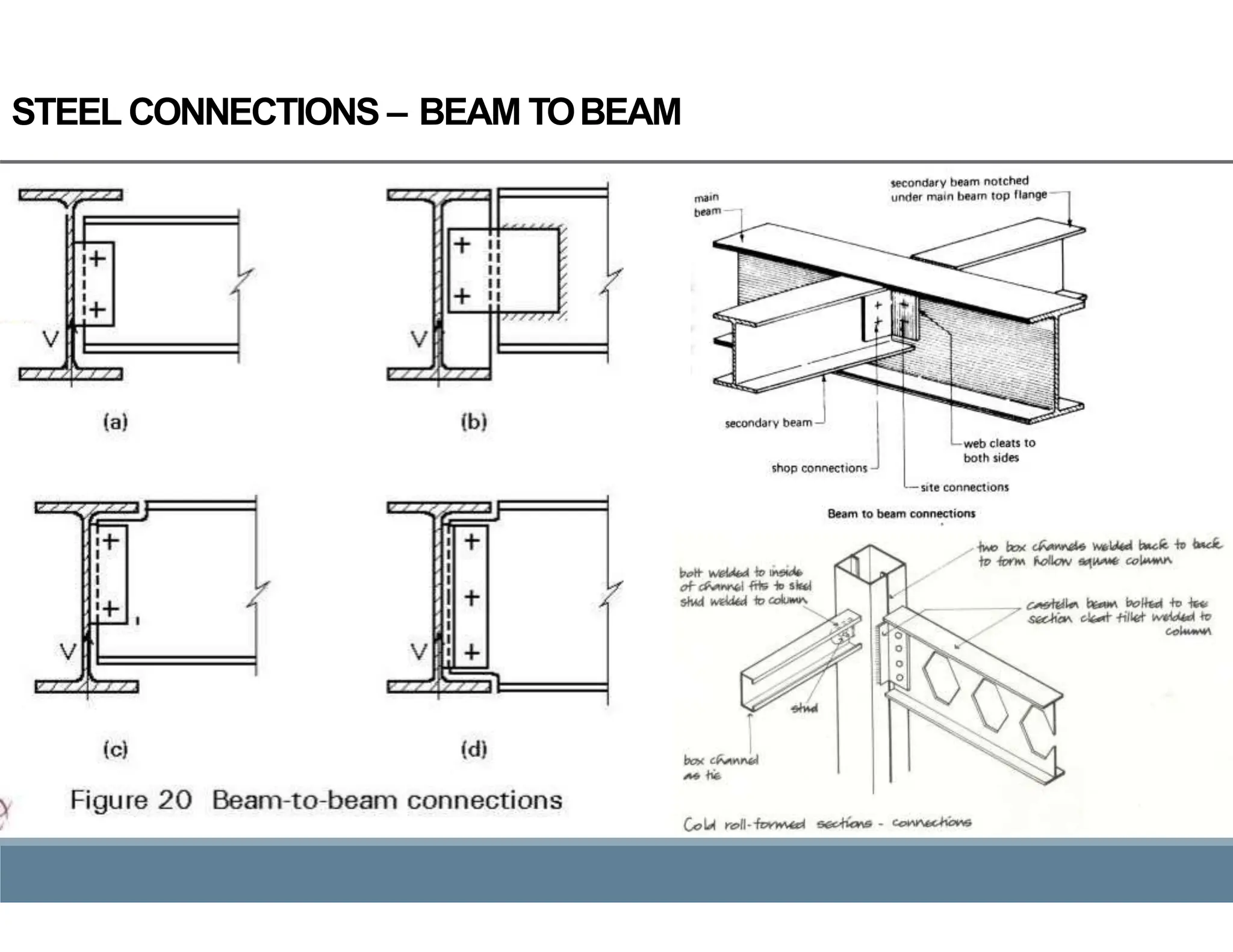

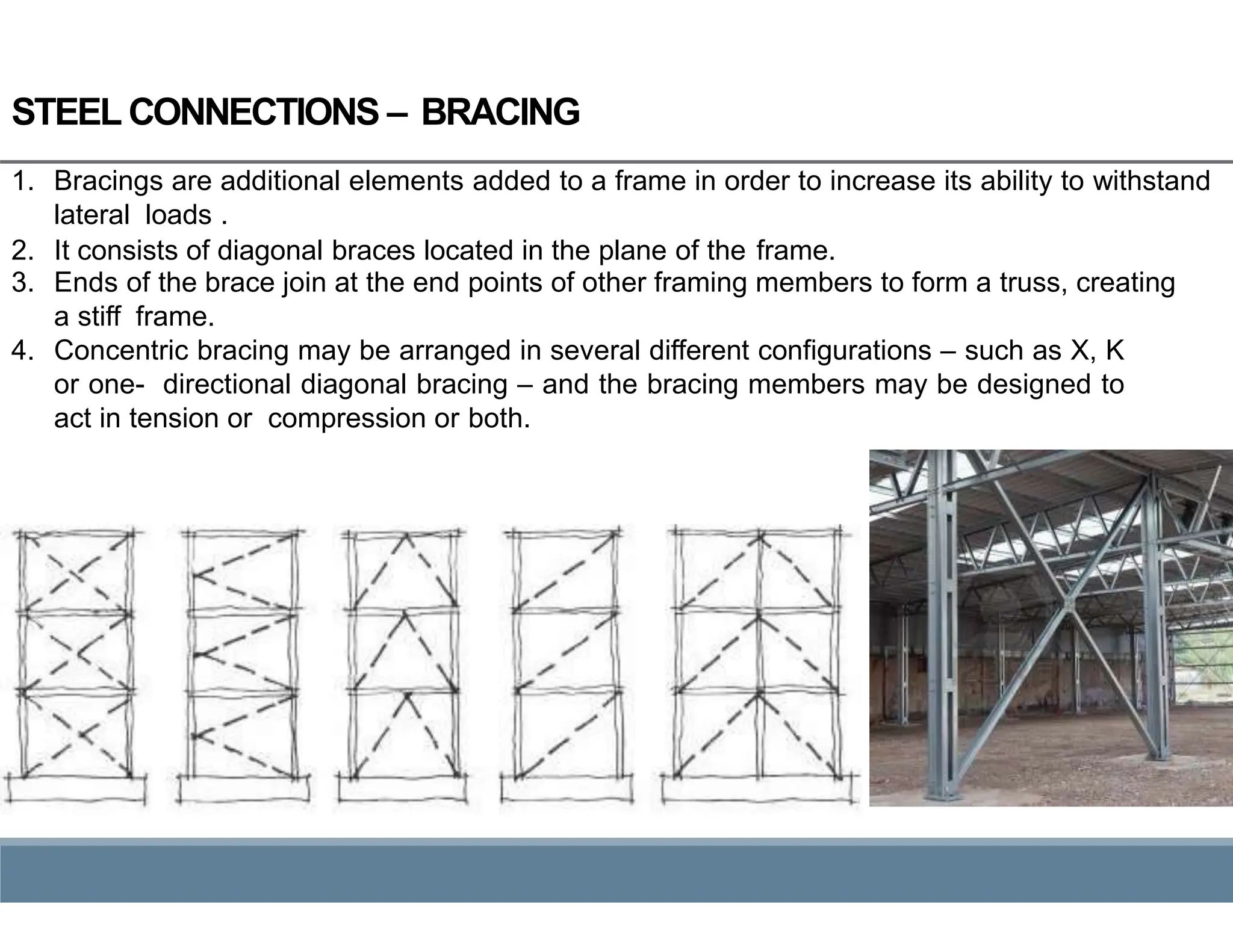

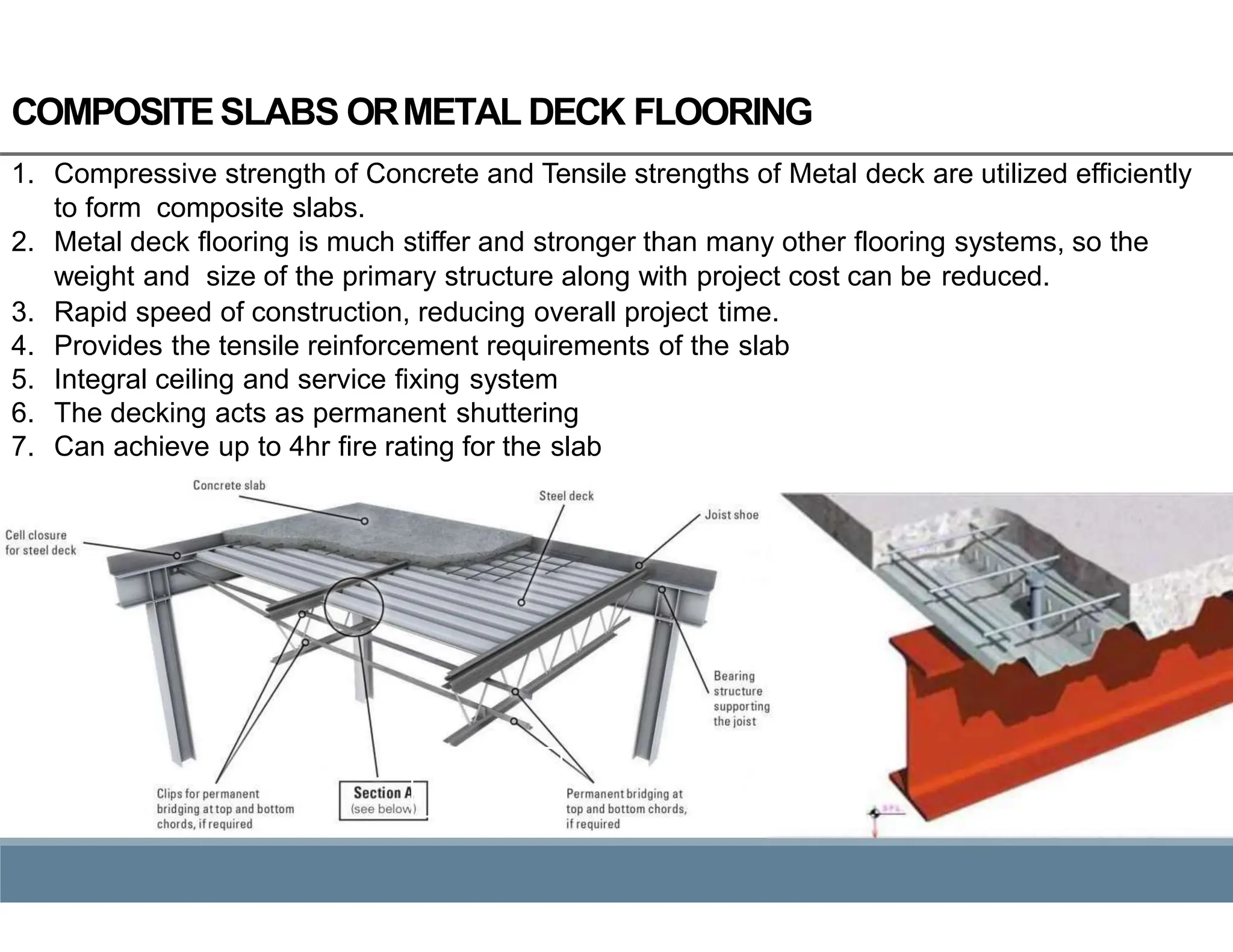

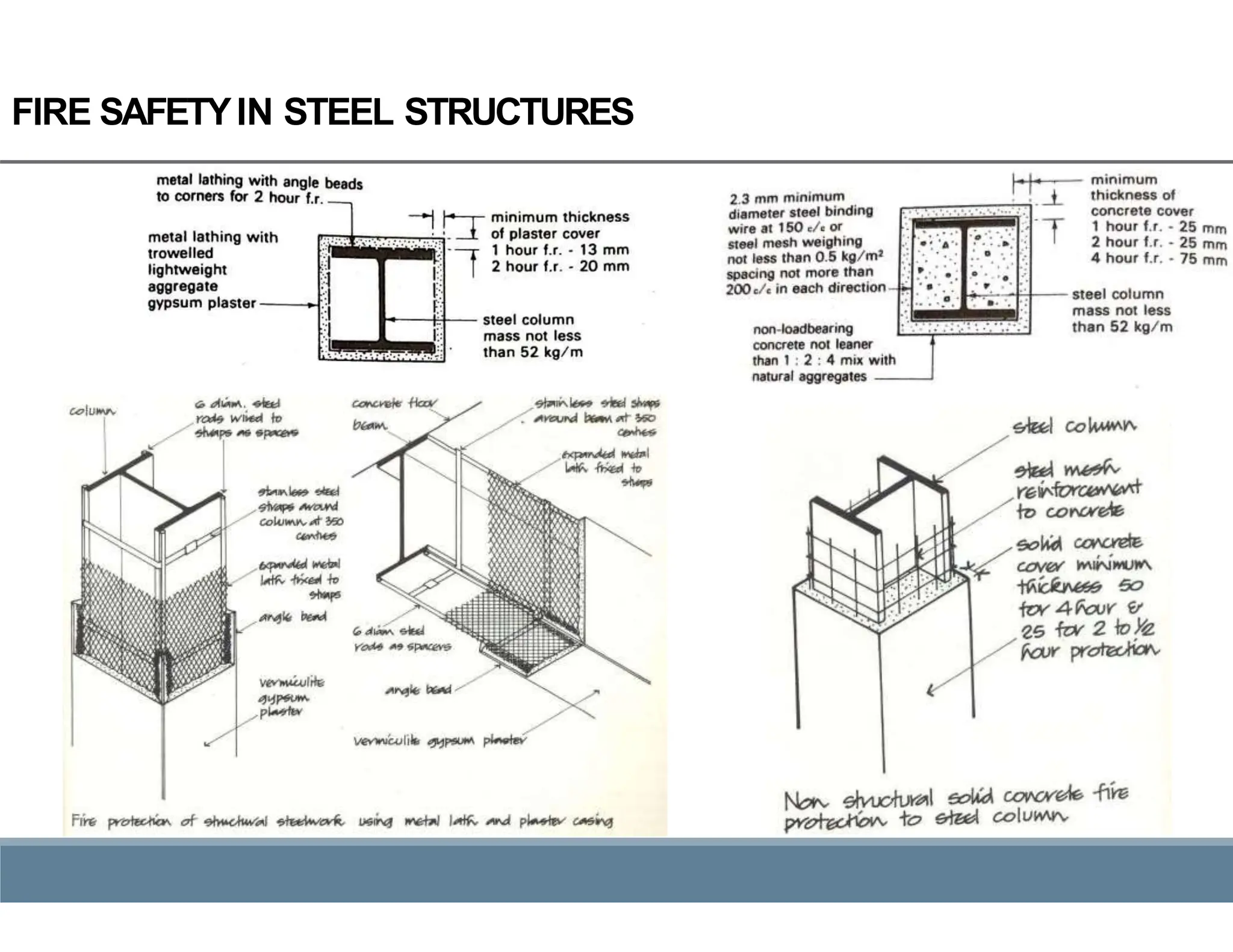

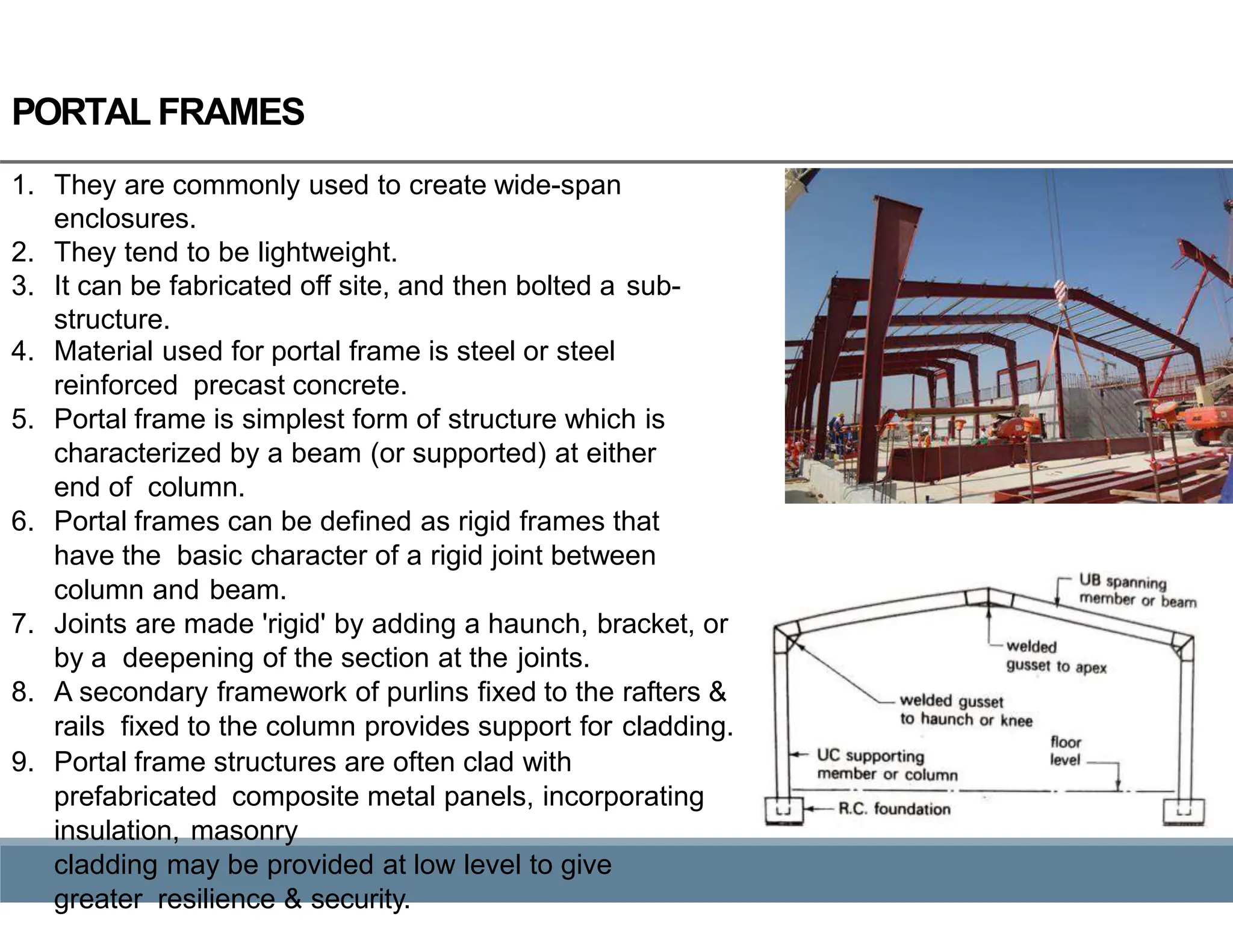

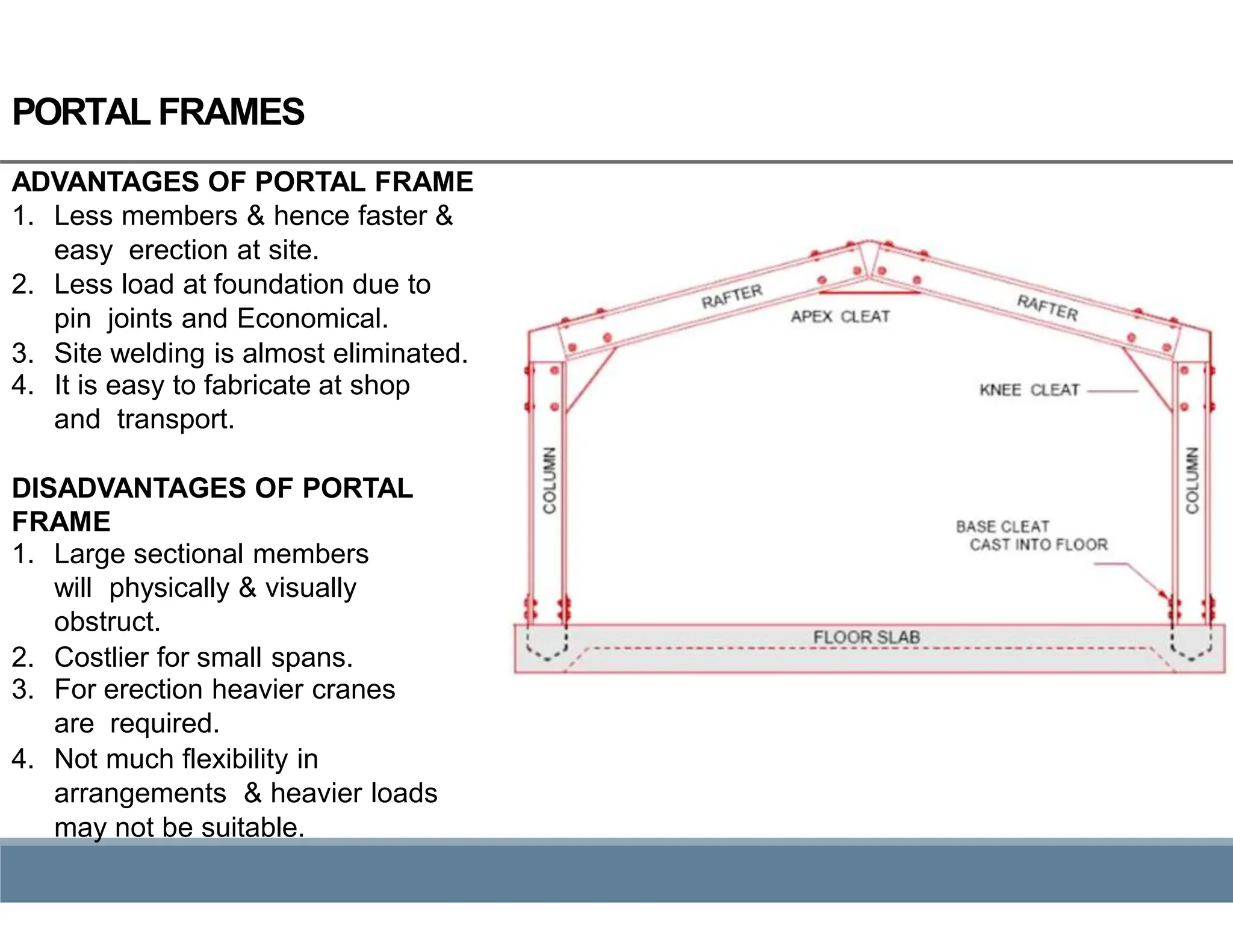

Steel structures are commonly used for high-rise buildings, long-span structures, industrial and warehouse buildings, and temporary structures due to steel's strength, light weight, speed of construction, and ability to create large spaces. Steel structures have advantages such as strength, flexibility, ductility, stability, earthquake resistance, and lighter weight compared to other materials. However, steel loses strength at high temperatures and is susceptible to corrosion. Common steel sections include angles, channels, I-beams, T-beams, round/square bars, and plates. Steel connections are made through bolting, riveting, and welding. Portal frames provide wide spans and are lightweight but require large members and cranes for erection.