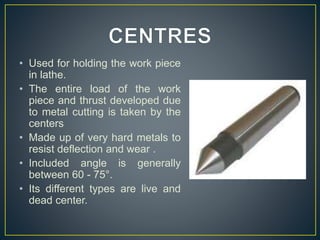

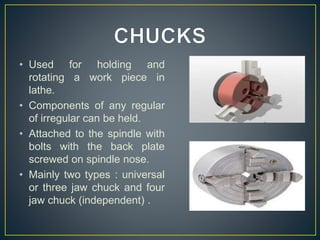

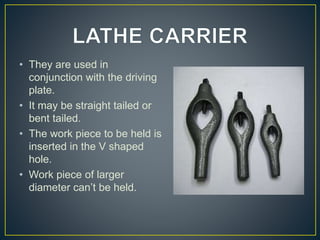

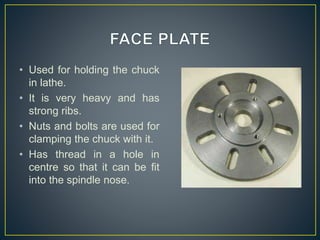

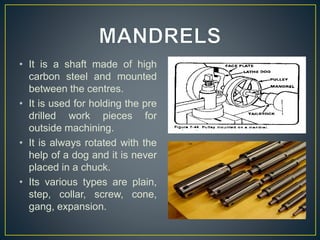

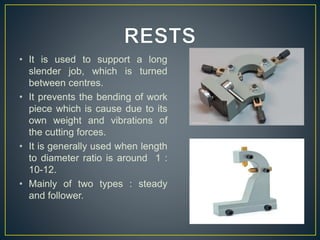

The document describes various components and their functions in a lathe, including centers, chucks, driving plates, and angle plates. It explains the types of centers (live and dead), chucks (three jaw and four jaw), and the use of different tools for holding and rotating workpieces. Additionally, it discusses the importance of using these components to prevent deflection and support longer jobs during machining.