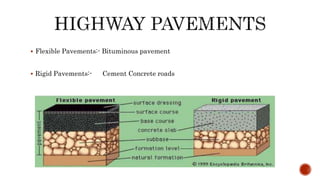

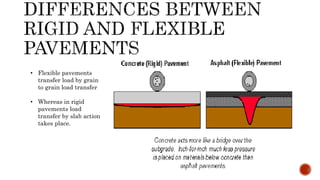

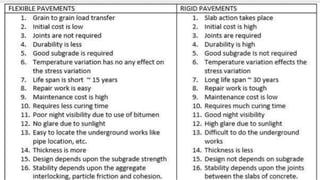

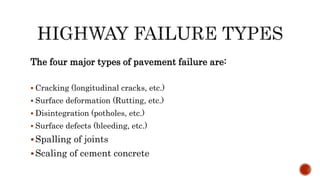

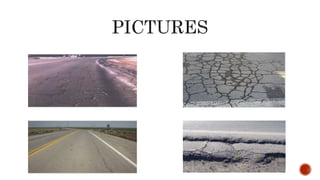

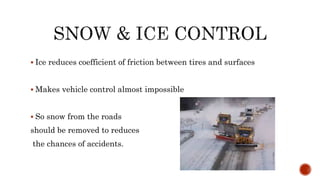

This document discusses highway pavements and maintenance. It describes the main types of highway pavements as flexible like bituminous, and rigid like cement concrete. The major causes of highway failure are rutting, heavy loads, instability and cracking. Highway maintenance aims to preserve the road, provide safety and efficient travel, and includes activities like patching, sealing, resurfacing, drainage maintenance, snow removal, bridge upkeep and traffic services. Key materials used are concrete, bitumen, asphalt and gravel. Periodic maintenance is needed to prolong a highway's lifespan.