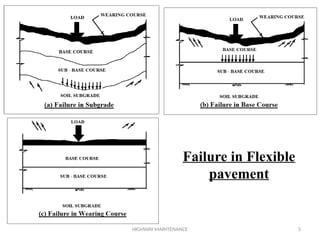

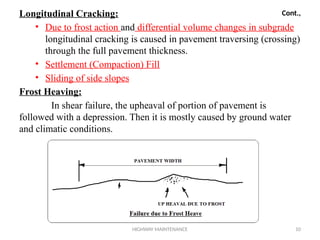

The document discusses the necessity and types of highway maintenance, highlighting the various causes of pavement failures such as material quality defects, construction issues, and environmental factors. It categorizes maintenance works into routine, periodic, and special repairs, and details specific types of failures in flexible and rigid pavements, including their causes and characteristics. Methods of pavement evaluation are also covered, emphasizing the importance of assessing structural integrity and surface conditions to maintain highway performance.