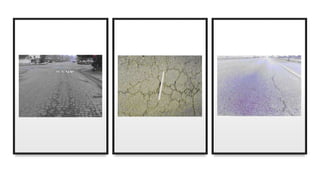

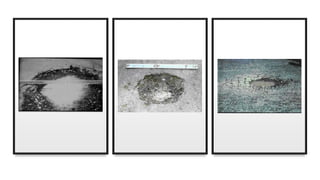

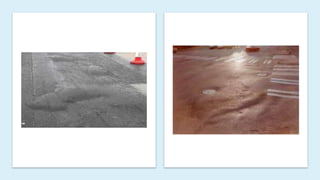

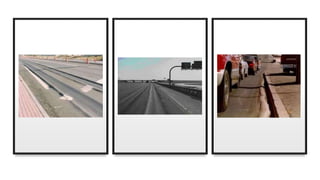

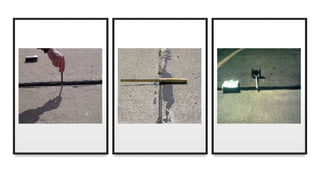

This document provides descriptions, causes, and repair strategies for various types of pavement distresses that can occur in both flexible (asphalt) and rigid (concrete) pavements. It discusses distresses such as fatigue cracking, block cracking, longitudinal cracking, rutting, patching, potholes, shoving, joint seal damage, corner spalling, mid-panel cracks, corner breaks, shattered slabs, and faulting/settlement. For each distress, it explains how to identify it and what factors may have led to its development, such as excessive traffic loads, poor drainage, or inadequate compaction during construction. It also recommends approaches for repairing different levels of distress severity.