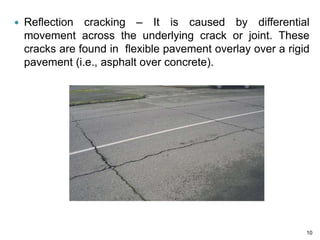

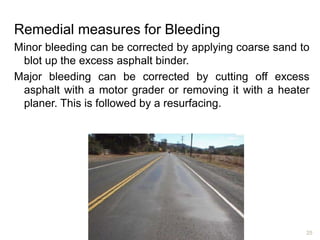

This document summarizes common pavement failures and their causes and maintenance methods. It describes 7 types of failures: cracking, potholes, rutting, shoving, raveling, bleeding. Cracking can be alligator, block, longitudinal/transverse, or reflection. Potholes form from untreated cracking. Rutting and shoving are caused by traffic loads. Raveling occurs from aggregate loss. Bleeding makes the surface shiny and tacky. The document provides details on each failure and recommends remedial measures such as patching, sealing, overlaying, or resurfacing. The goal is to repair the pavement and prevent further deterioration.