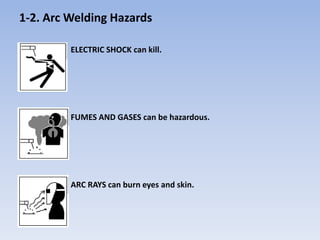

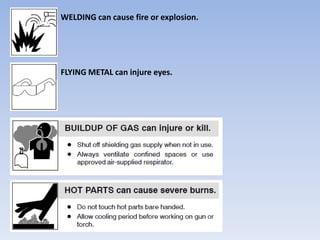

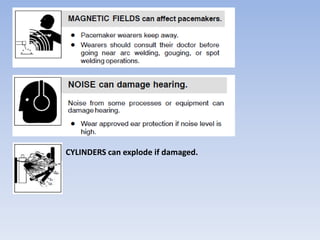

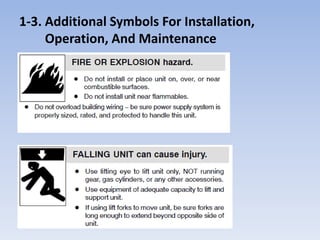

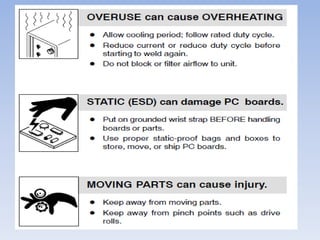

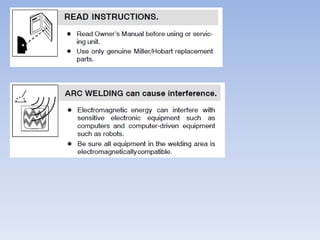

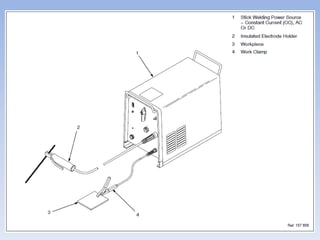

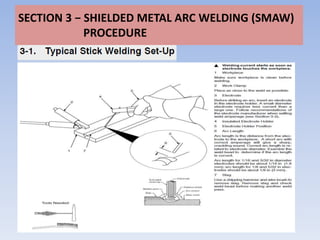

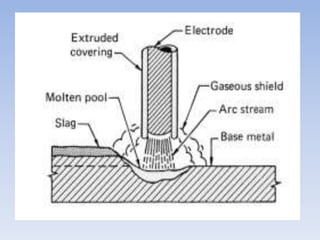

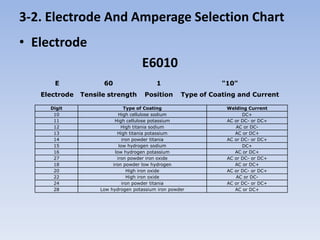

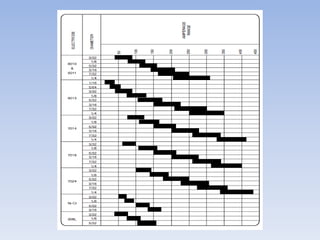

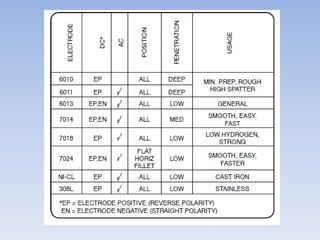

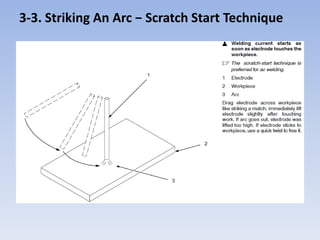

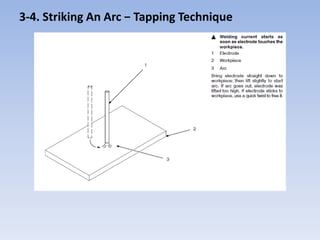

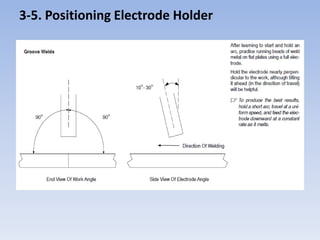

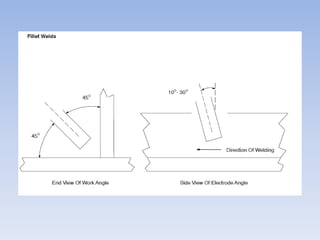

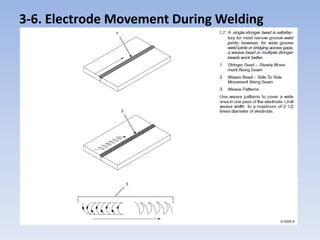

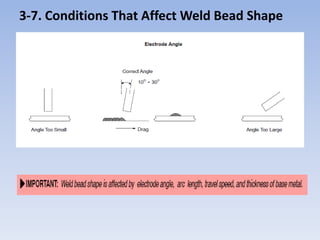

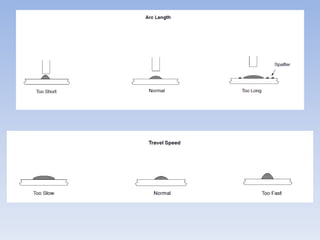

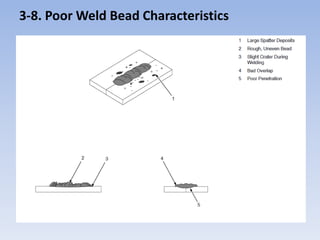

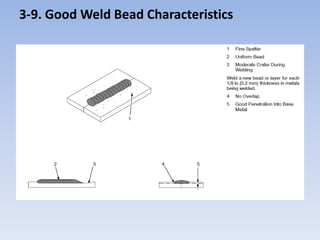

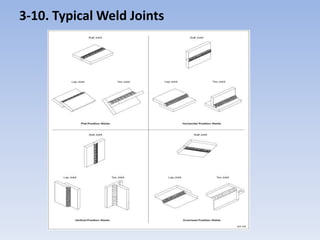

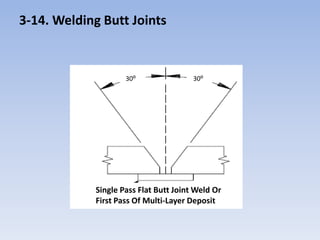

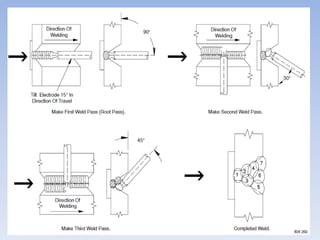

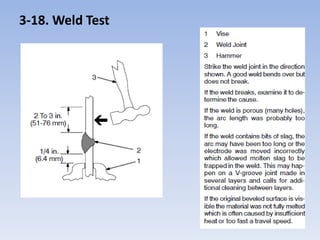

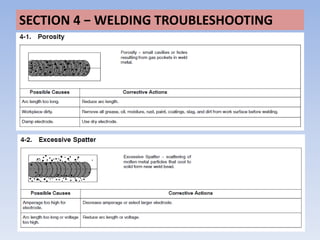

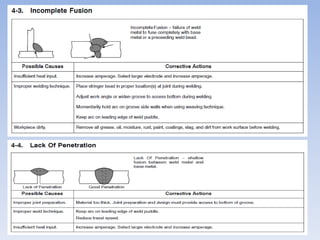

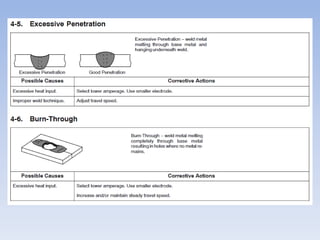

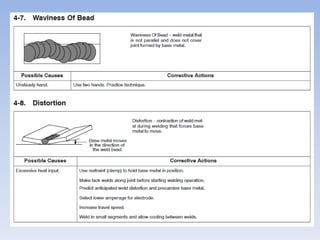

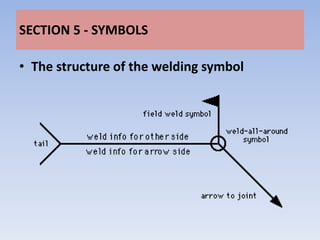

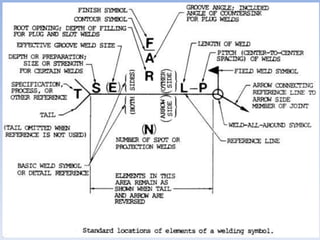

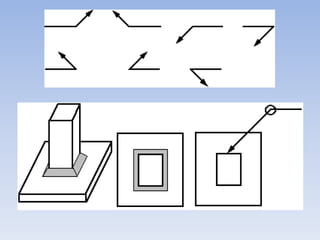

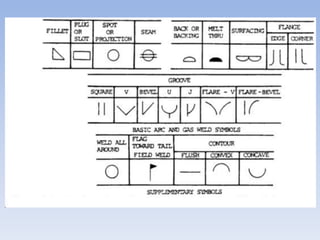

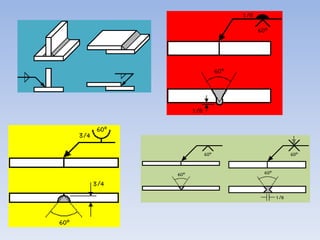

This document provides safety precautions and instructions for shielded metal arc welding (SMAW). It discusses hazards of electric shock, fumes, arc rays, fire and explosions, and flying metal. It also covers principles of SMAW, electrode and amperage selection, techniques for striking an arc and electrode movement, factors that affect weld bead shape, and examples of good and poor welds. Symbols used in welding are explained.