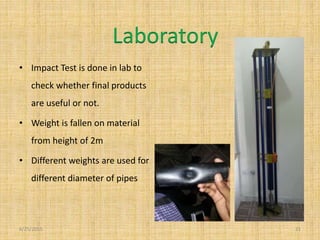

This document provides information about Newtech Pipe Industry located in Islamabad, Pakistan. It discusses the group members, machinery suppliers, production details, raw materials, manufacturing process, waste management, and testing facilities. The industry produces HDPE pipes using an automated process run primarily by one person. Pipes are produced in diameters ranging from 2 to 12 inches and are used for applications like water supply, gas transportation, and plumbing.