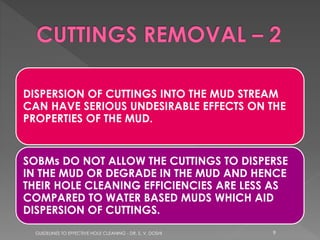

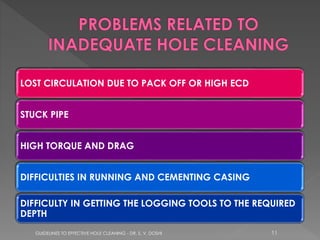

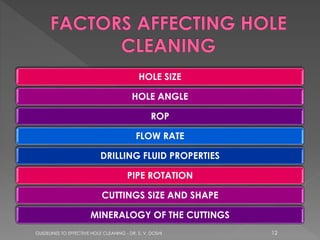

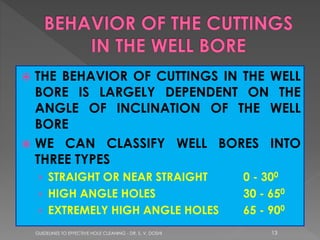

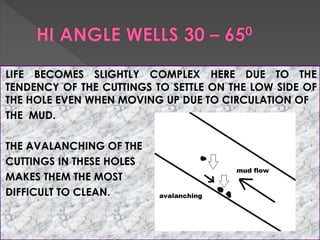

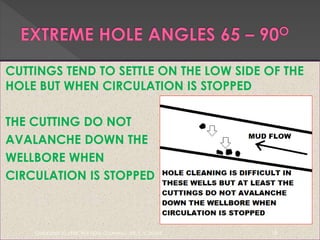

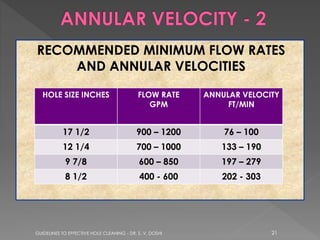

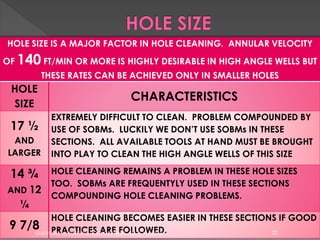

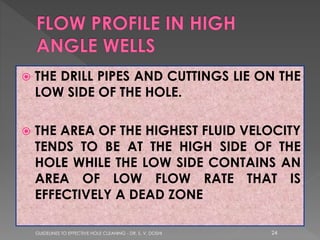

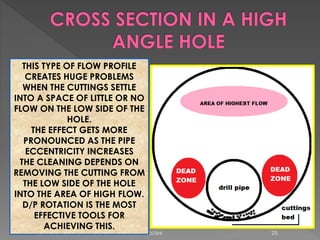

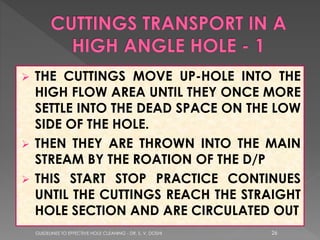

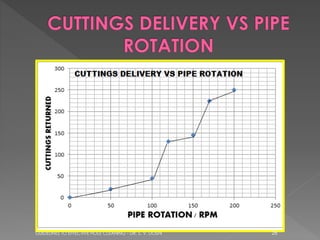

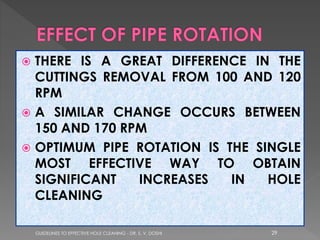

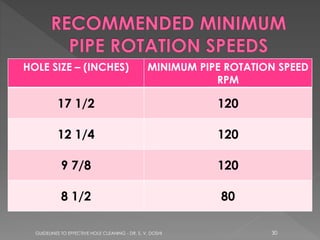

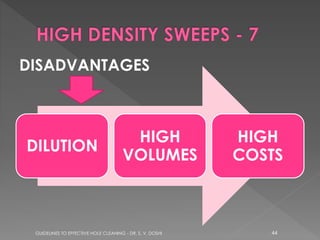

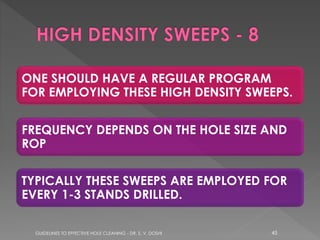

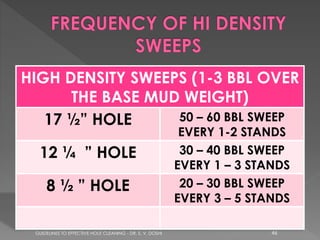

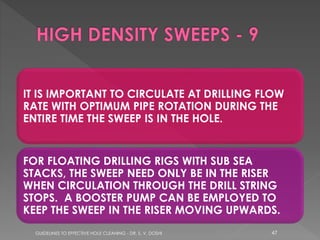

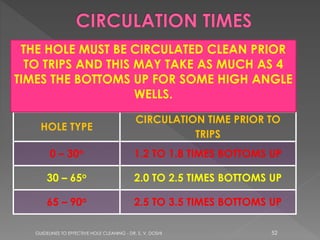

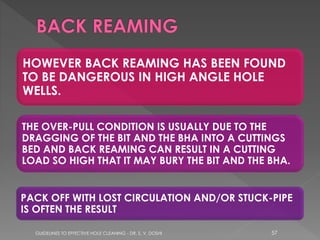

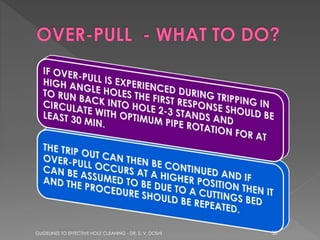

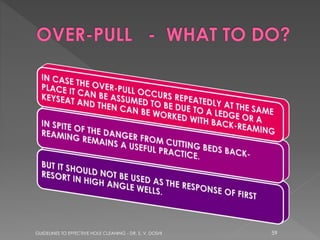

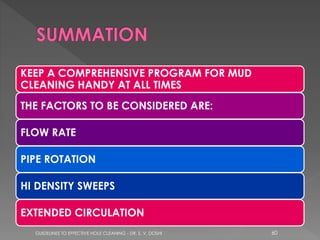

This document provides guidelines for effective hole cleaning when drilling wells. It discusses that hole cleaning, which is removing drilled material from the borehole, is an important but often overlooked part of the drilling process. For high angle and deviated wells, cuttings follow a complex path down the hole and can accumulate on the low side of the borehole if not properly removed. The key factors that influence effective hole cleaning are discussed, including maintaining adequate flow rates and annular velocities, optimizing drilling fluid properties, and using drill pipe rotation to help move cuttings. High density sweeps are also recommended to help clean cuttings from deviated wellbores.