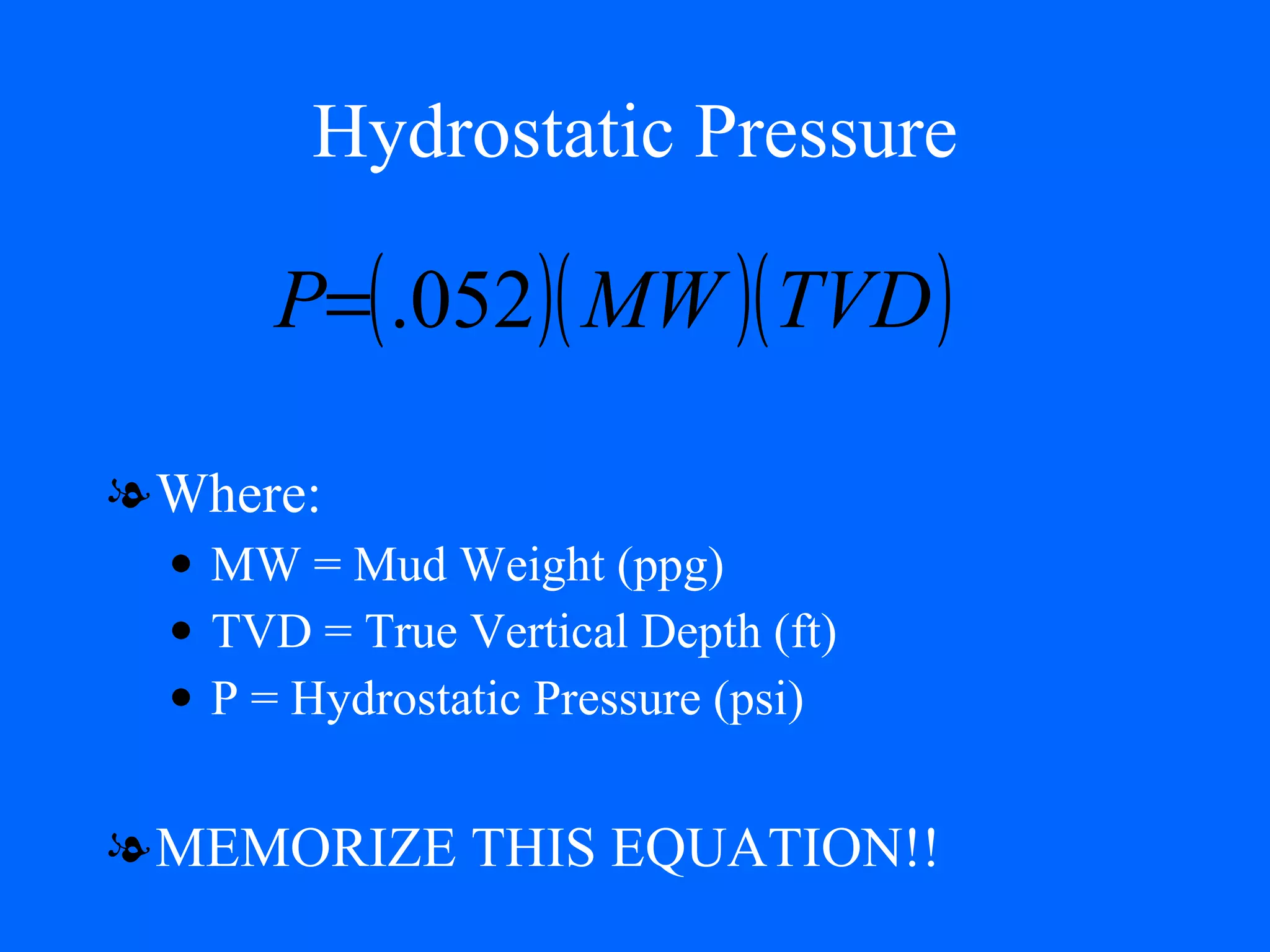

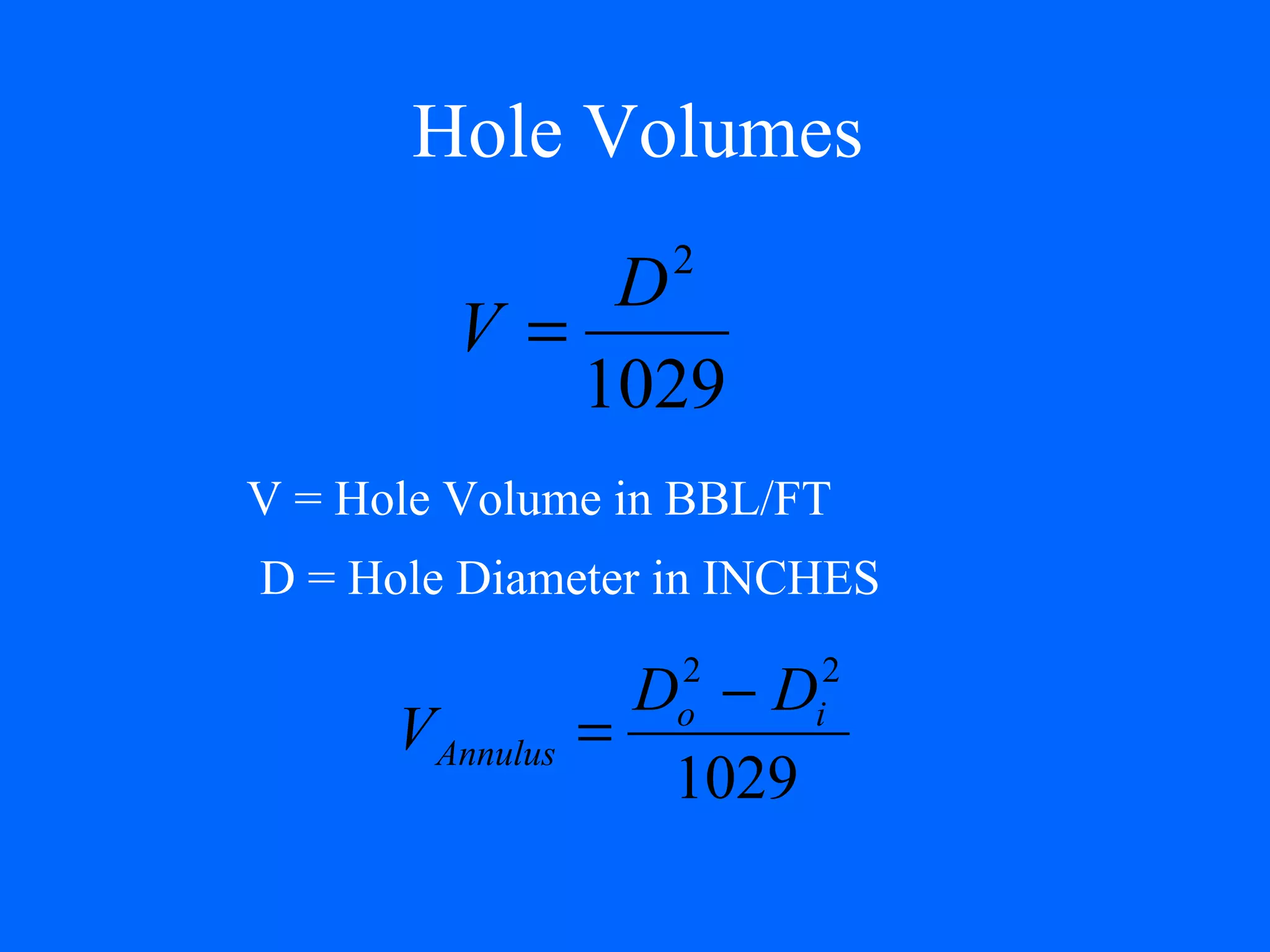

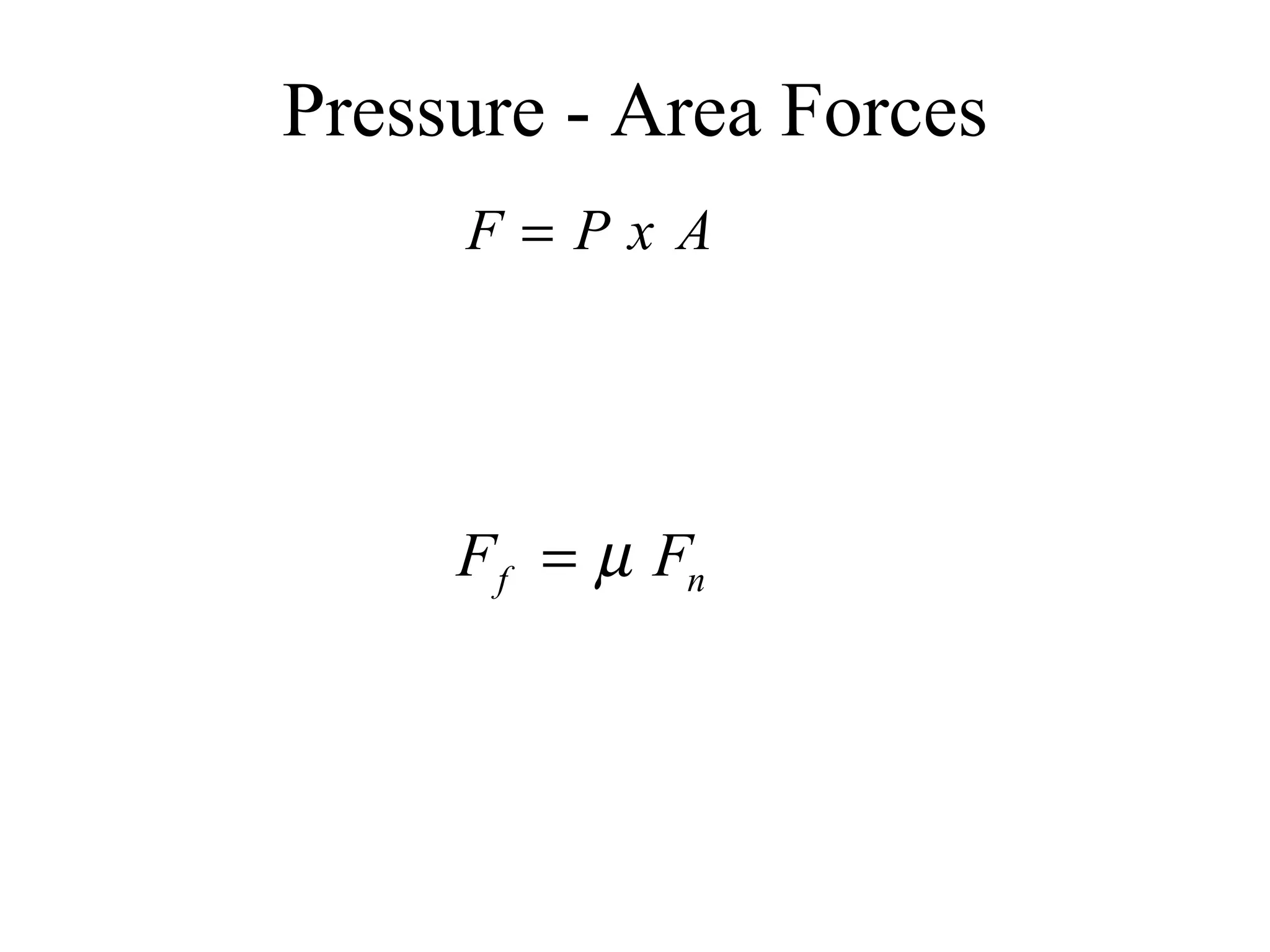

The document discusses various causes and prevention methods for stuck pipe while drilling. It covers solids induced pack-off, differential sticking, mechanical/wellbore geometry sticking, and inadequate hole cleaning. Key prevention strategies include maintaining proper mud properties, minimizing differential pressures, anticipating drilling hazards, and making wiper trips to clean the hole.