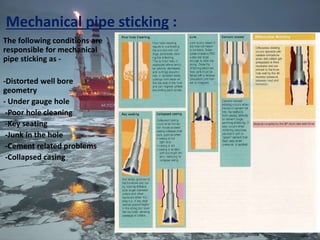

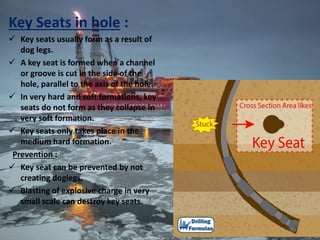

This document discusses downhole problems that can occur while drilling wells and methods to prevent them. It covers various downhole problems like pipe sticking, pipe failure, dog legs, key seats, shale problems, and lost circulation. Pipe sticking can be mechanical or differential. Dog legs occur from changes in formation dip or bit weight. Key seats form from doglegs. Shale problems include hole enlargement, caving, sloughing, and heaving. Lost circulation happens when mud pressure exceeds formation pressure. Prevention methods include using inhibitive muds, slowing drill string movement, and drilling with low pump pressure and fluid velocity. Faster drilling can mitigate many downhole problems by reducing shale exposure time and mud costs.