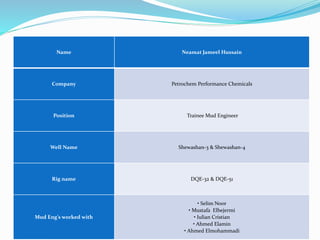

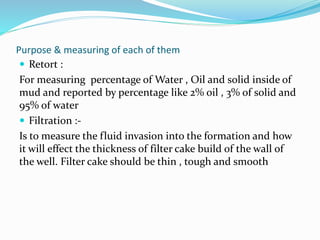

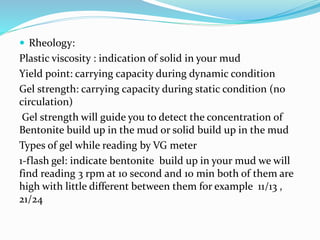

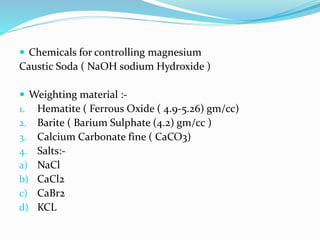

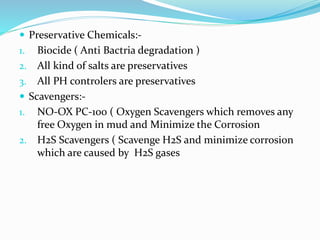

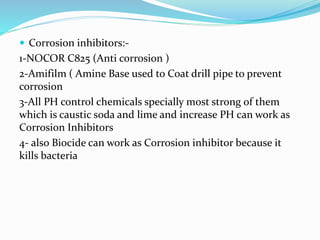

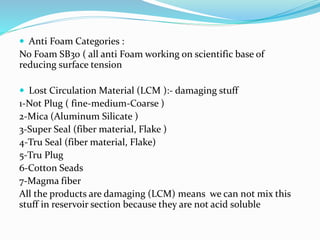

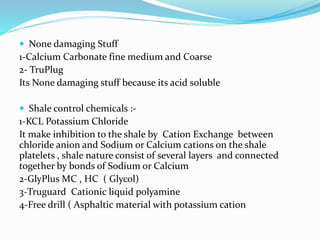

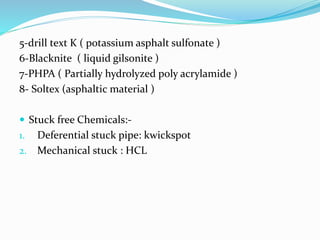

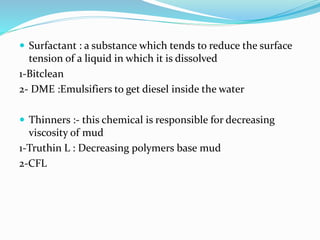

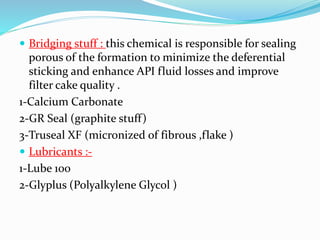

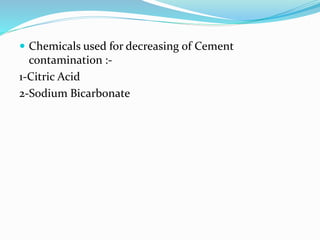

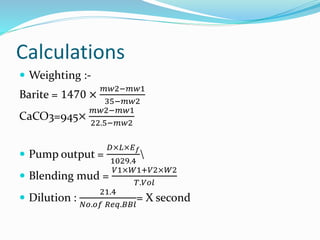

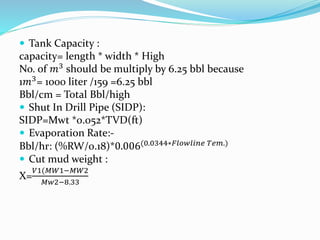

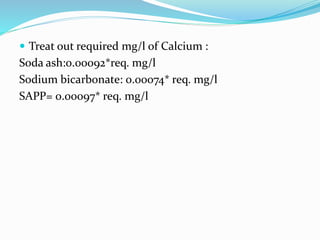

This document provides an overview of a mud engineer trainee's work experience with two rigs, DQE-32 and DQE-51. It discusses the functions of drilling fluid, types of mud, testing procedures, chemical categories used in mud systems, calculations, cementing operations, formation and downhole problems, and general mud engineering information. The trainee thanks their mentors at Petrochem for providing training support over their 3-month internship.