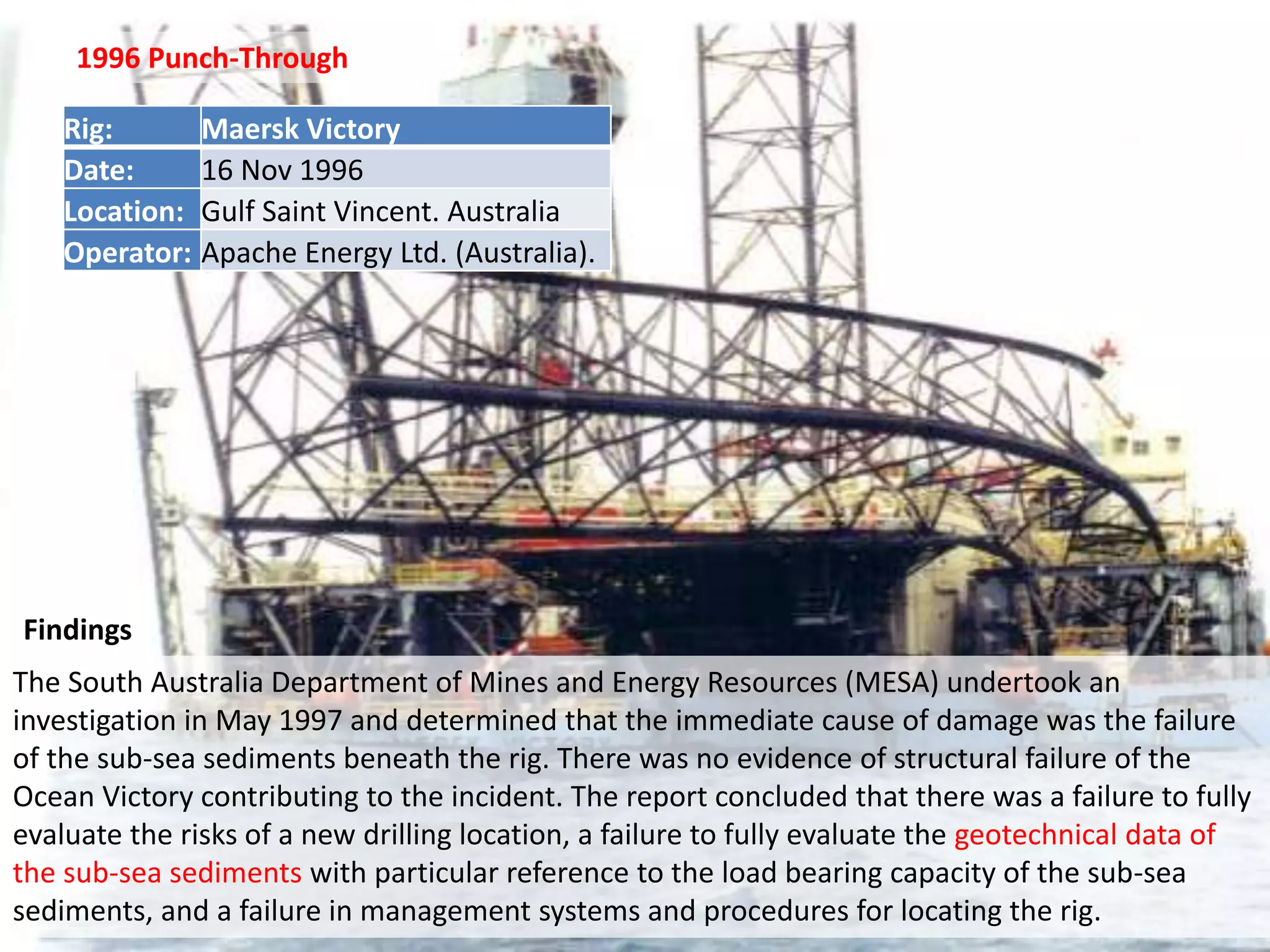

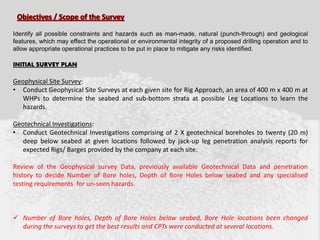

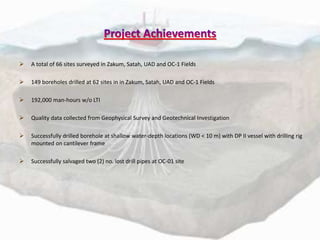

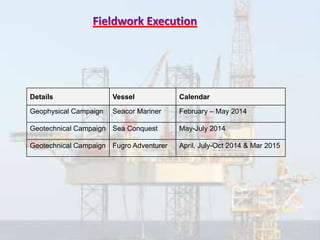

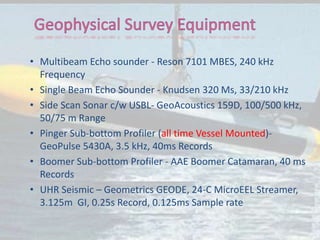

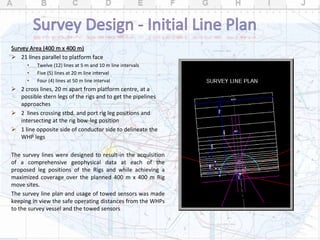

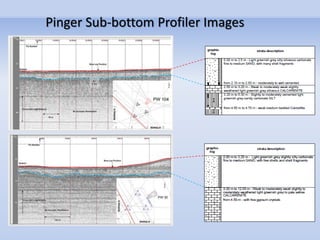

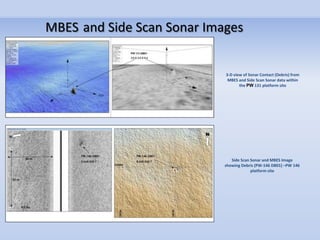

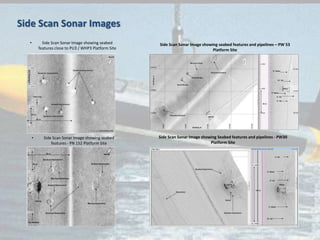

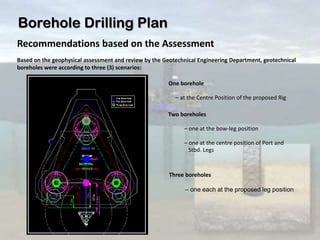

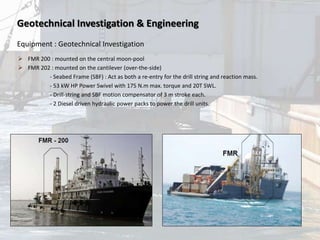

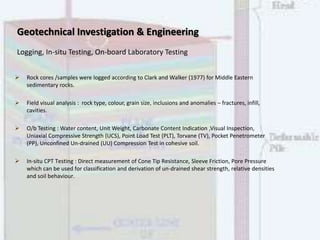

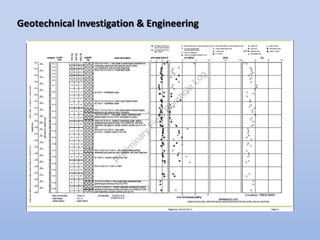

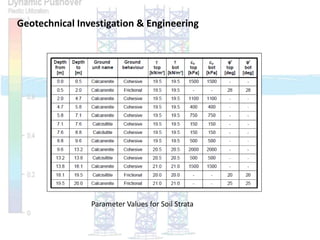

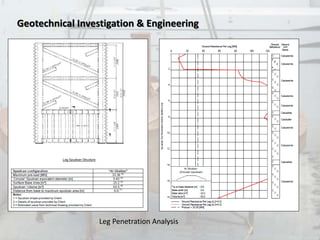

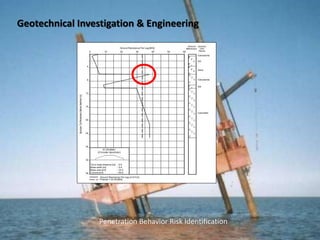

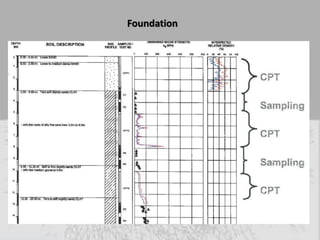

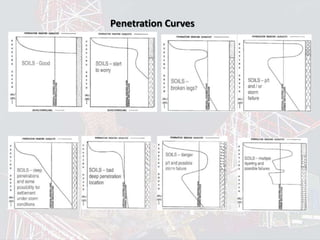

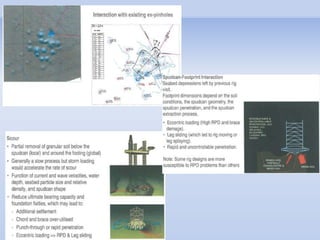

The document summarizes a geophysical and geotechnical survey conducted of 61 sites for rig and barge moves. A comprehensive data acquisition campaign involved geophysical surveying and geotechnical borehole drilling and testing to identify seabed and subsurface hazards. The surveys found debris and disturbed seabed at some locations that could impact rig stability. The data obtained will support safe rig and barge positioning by informing plans to mitigate risks from geological features or man-made hazards.