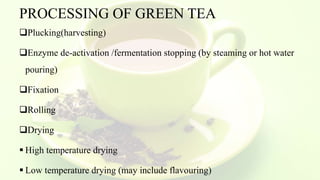

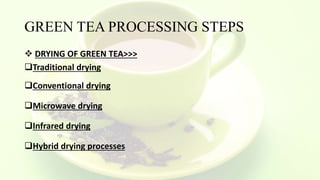

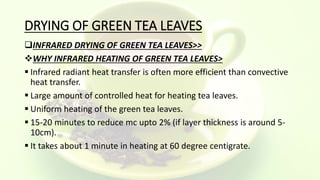

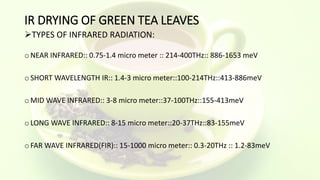

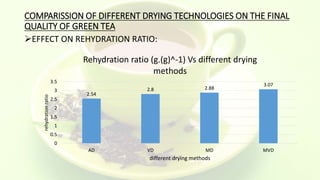

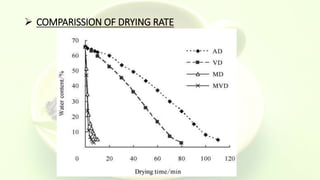

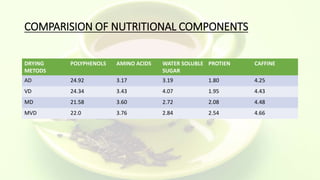

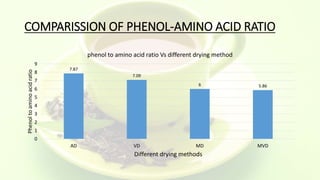

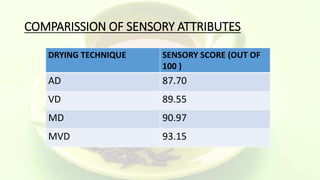

Green tea processing involves several steps including plucking, enzyme deactivation through steaming, rolling, and drying. Traditional drying methods include sun drying and shade drying but modern methods like convection drying, microwave drying, infrared drying, and hybrid processes are now commonly used. Microwave drying provides uniform and rapid heating but can damage tea leaves. Infrared drying also allows for fast, controlled, and uniform heating without contact. Comparison of drying methods found microwave vacuum drying produced the highest quality tea based on sensory attributes and rehydration ratio, though conventional methods can better retain certain nutrients like amino acids. Overall, modern methods can significantly reduce drying time but require more capital investment.